- Home

- Automated Welding Systems

Top Manufacturer of Automated Welding Systems for Wholesale and OEM Supply from China

Lin Laser Technology Co., Ltd. is a leading manufacturer and supplier of high-quality automated welding systems in China. Our automated welding systems are designed with advanced technology to ensure maximum efficiency, accuracy, and productivity.

Our automated welding systems are perfect for various applications and industries such as aerospace, automotive, construction, and more. With our expertise and experience in welding technology, our automated welding systems are guaranteed to provide consistent and high-quality results every time.

At Lin Laser Technology Co., Ltd., we use only the finest quality materials and components to ensure durability and longevity of our systems. Our automated welding systems are also easy to operate, maintain, and require minimal supervision, allowing you to save time, labor costs, and boost your overall production output.

Choose Lin Laser Technology Co., Ltd. for your automated welding needs and experience the difference in quality, efficiency, and cost-effectiveness. Contact us today to learn more about our automated welding systems and how we can help you improve your welding process.

Lin Laser Technology Co., Ltd.,

Company News

Related News

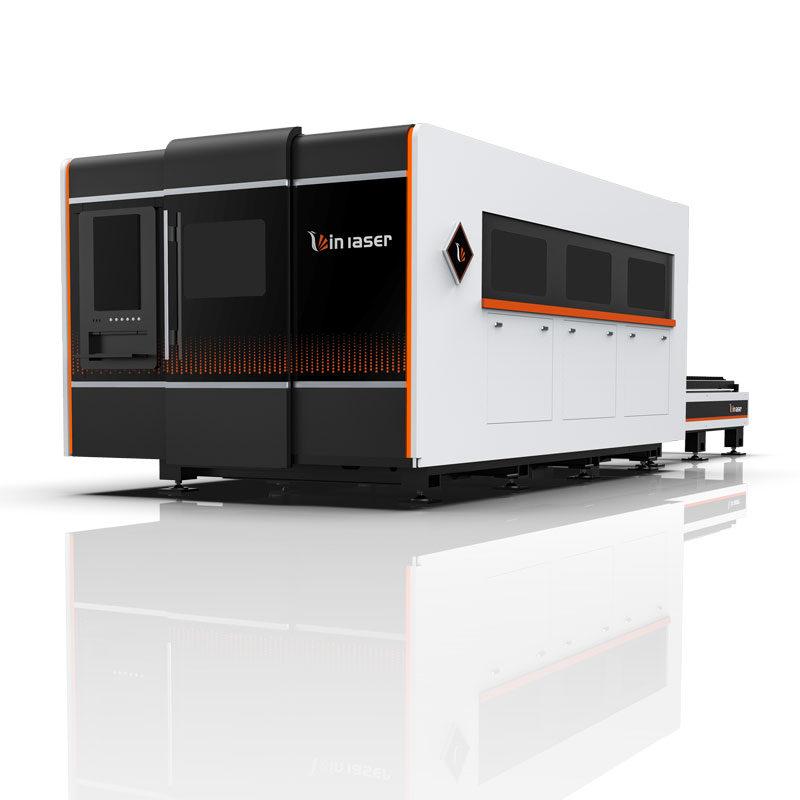

High power&Ultra-large format metal sheet fiber laser cutting machine

We are a factory specializing in the production of high-power and ultra-large format metal sheet fiber laser cutting machines. Our advanced machines are designed for precision and efficiency, delivering unparalleled results for all your metal cutting needs. Trust us for quality, durability, and affordability!

Laser Cleaning Machine - High-tech Surface Cleaning Solution for Multiple Industries

Our Laser Cleaning Machine is a sophisticated solution for thoroughly cleaning surfaces in various industries. As a factory, we deliver top-quality products that meet your needs and exceed your expectations.

SmartSheet - The Ultimate Automated Tower Storage for Sheet Metal Parts

SmartSheet is the perfect storage solution for sheet metal parts in any factory. Our automated tower system maximizes efficiency and space, improving productivity.

Revolutionize your industry with our 3-in-1 laser welding cleaning and cutting machine

Revolutionize your industry with our 3-in-1 laser welding cleaning and cutting machine! As a factory, we offer high-quality equipment for all your industrial needs. Upgrade your processes and increase efficiency today.

3 in 1 Laser Welding Cleaning and Cutting Machine

As a factory, we offer the convenient and efficient 3 in 1 Laser Welding Cleaning and Cutting Machine. This versatile tool is perfect for all your industrial needs.

Blade Cleaner - Revolutionizing Blade Cleaning with High Speed Efficiency

Blade Cleaner is a game-changer in the world of blade cleaning. Our factory produces top-notch, high-speed efficiency products that are designed to revolutionize your cleaning process. Get your hands on Blade Cleaner today for the ultimate cleaning experience!

Whole cover&Exchange platform Fiber Laser Cutting Machine

Fiber Laser Cutting Machine - Whole cover&Exchange platform from our factory. Get efficient and precise cutting with our advanced technology. Order now!

Laser Cleaning Machine

Looking for a reliable factory that produces high-quality laser cleaning machines? Look no further than our top-of-the-line product line. Our laser cleaning machines are perfect for removing rust, paint, and other unwanted substances from a variety of surfaces. Contact us today to learn more.

High Energy Fiber Laser Cutting Machine - Unleash Your Cutting Potential

As a factory specializing in high-energy fiber laser cutting machines, we offer a cutting-edge solution to unleash your cutting potential. Experience precision, speed, and versatility with our top-notch equipment.

Automatic tower storage device for sheet metals

Looking for an efficient way to store your sheet metals? Our Automatic Tower Storage Device for Sheet Metals is the perfect solution! As a factory, we understand the importance of maximizing space and productivity. Try our product today!

Revolutionize your welding process with our handheld laser welder

Revolutionize your welding process with our handheld laser welder. As a factory, we specialize in manufacturing high-quality welding equipment that's perfect for various industrial applications. Boost your productivity today!

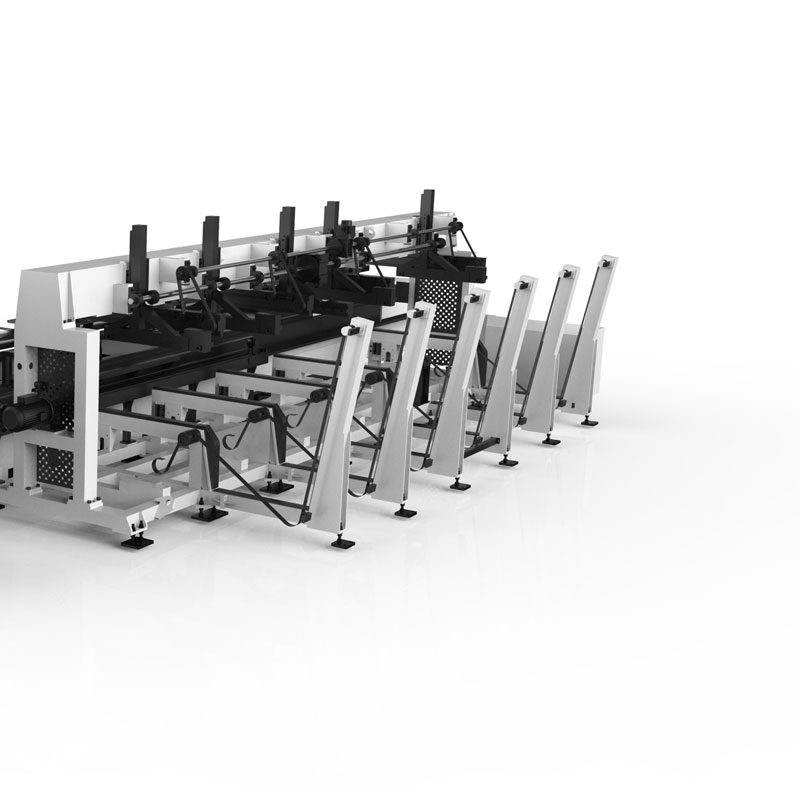

Tube machine automatic loading and unloading device

Looking for efficient and reliable automatic loading and unloading systems for your tube machine? Look no further! Our factory offers top-quality products to streamline your production processes and boost efficiency. Contact us today to learn more!

Blade cleaner

Get your blades looking new again with Blade Cleaner. As a factory, we ensure high-quality cleaning for all types of blades. Order now for a spotless finish.

Sheet&Tube Dual-use Fiber Laser Cutting Machine

As a factory, we offer the Sheet&Tube Dual-use Fiber Laser Cutting Machine. This multifunctional machine can help you achieve precise and efficient cutting on both sheets and tubes.

Our CNC press brakes feature unrivaled precision and efficiency

Looking for precise & efficient CNC press brakes? Look no further than our factory! Our products feature unrivaled precision & efficiency. Order now! #CNCPressBrakes #Precision #Efficiency #Factory

- Top Manufacturer of Automated Welding Systems in China - OEM Solutions Available

- Reviews

- Related Videos

Automated Welding Systems are the future of welding. With the advanced technology and precision engineering, automated welding systems make the process faster, more efficient, and higher quality. The systems use advanced software and robotics to produce consistent and accurately welded parts with minimal waste material. There are various types of automated welding systems available in the market. From robotic welding machines to automated welding cells, these systems are designed to suit various industries and applications. Automated welding systems have become an essential part of manufacturing plants, especially in industries like aerospace, automotive, and construction. One of the key benefits of these systems is improved safety. Welding can be a dangerous job, but with these systems, operators can work remotely and safely. Additionally, the consistency and precision of automated welding systems increase the accuracy of welding, resulting in fewer reworks and better-quality end-products. The automated welding systems are easy to integrate into existing workflows, making them an ideal choice for companies looking to improve productivity and efficiency. They not only increase the speed of production but also reduce labor costs significantly. In conclusion, automated welding systems are a must-have for any company that needs consistent, high-quality welding output while optimizing their resources. With their advanced capabilities and multiple benefits, automated welding systems are indeed revolutionizing the welding industry.

Automated welding systems are an excellent technological advancement in the world of welding. These systems make welding work fast, efficient, and error-free. The use of automated welding systems allows for a more precise production of quality welds. By automating welding, manufacturers can increase productivity and reduce the occurrence of defects in productions. The automated welding systems also provide a much safer environment for workers as they minimize the need for human interaction with hazardous substances. With a wide range of automated welding systems in the market today, it has become easy for companies to choose the best system that meets their welding needs.

The automated welding systems are perfect for modern industries that require a high level of precision and efficiency. These systems are designed to simplify welding tasks, making it easier and faster to produce high-quality welds every time. The systems are equipped with advanced sensors and fully automated controls that help to ensure consistent weld quality, even in complex welding applications. With automated welding systems, there is no need for manual welding, which saves time and money while also reducing labor costs. They are well worth the investment, especially for manufacturers who rely on welding to deliver quality products.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours