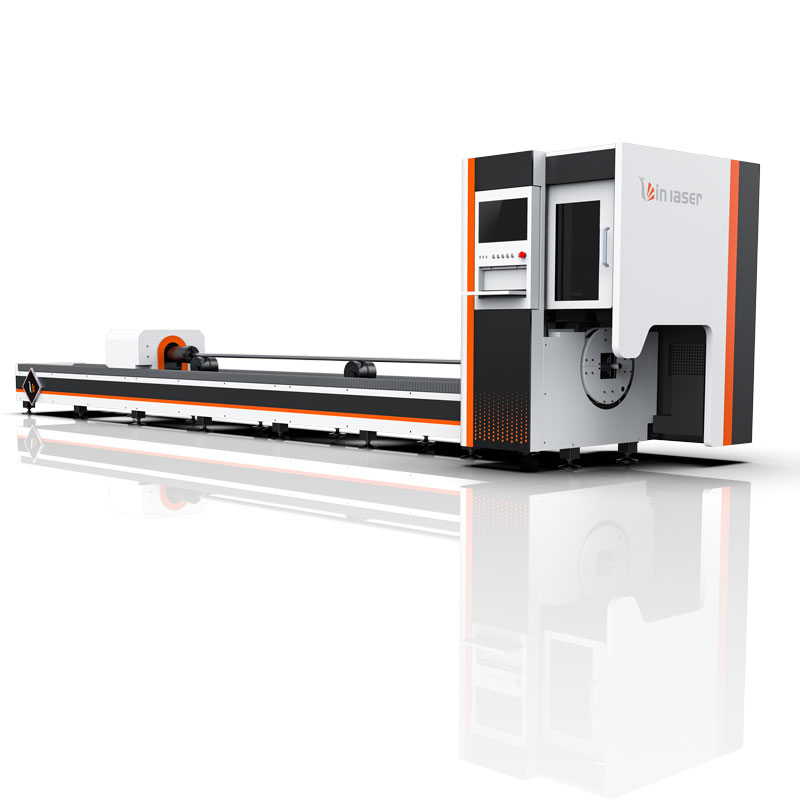

Advanced Pipe Laser Machine for Efficient and Precise Pipe Cutting

By:Admin

The pipe construction industry has seen a significant transformation with the introduction of the latest Pipe Laser Machine from [Company Name]. This state-of-the-art technology has been developed to streamline the pipe installation process and enhance the overall efficiency of construction projects.

[Company Name] has been a leading manufacturer of construction machinery and equipment for over two decades. With a strong focus on innovation and technological advancement, the company has constantly strived to develop cutting-edge solutions to meet the evolving demands of the industry. The Pipe Laser Machine is the latest addition to their impressive portfolio of products, and it has quickly gained traction for its exceptional performance and reliability.

The Pipe Laser Machine is designed to offer precise and accurate alignment for pipe installation, ensuring that the pipes are laid out with utmost precision. This not only reduces the margin for error but also helps in optimizing the use of materials, resulting in cost savings for construction companies. The machine is equipped with advanced laser technology that enables it to accurately measure and align pipes, regardless of the terrain or environmental conditions.

One of the key features of the Pipe Laser Machine is its versatility and adaptability to various pipe diameters and materials. This ensures that it can be used for a wide range of construction projects, including sewer lines, drainage systems, water pipelines, and more. The machine can be easily calibrated to accommodate different pipe sizes, thereby offering a high level of flexibility for contractors and construction crews.

In addition to its precision and adaptability, the Pipe Laser Machine is also known for its user-friendly interface and intuitive controls. This makes it easy for operators to set up and operate the machine, reducing the need for extensive training and specialized skills. The machine also comes with an array of automated functions that further streamline the pipe installation process, allowing for faster and more efficient project completion.

Furthermore, the Pipe Laser Machine is equipped with robust construction and durable components, ensuring its longevity and reliability even in rugged construction environments. This translates to lower maintenance costs and minimal downtime, ultimately contributing to higher productivity and profitability for construction firms. The machine is built to withstand the rigors of the construction site, offering a dependable and consistent performance throughout its lifespan.

The impact of the Pipe Laser Machine on the construction industry has been nothing short of revolutionary. It has significantly accelerated the pipe installation process, allowing for quicker project completion and faster turnaround times. This not only benefits construction companies in terms of increased productivity but also contributes to overall project efficiency and client satisfaction.

As the construction industry continues to evolve and embrace technological advancements, the Pipe Laser Machine has emerged as a game-changer, redefining the standards for pipe installation and construction practices. Its innovative features and superior performance have set a new benchmark for efficiency and precision in pipe construction, making it an indispensable tool for modern construction projects.

In conclusion, the Pipe Laser Machine from [Company Name] has raised the bar for pipe installation in the construction industry. Its advanced technology, precision alignment, versatility, and user-friendly interface make it an invaluable asset for construction firms looking to optimize their pipe construction processes. With its proven track record of enhancing project efficiency and performance, the Pipe Laser Machine has undoubtedly become a cornerstone of modern pipe construction practices.

Company News & Blog

New High-Quality Machinery for Increased Production Efficiency

In the ever-evolving world of manufacturing, the need to have the most advanced and versatile equipment is essential for companies to stay ahead of the competition. In order to keep up with the increasing demand for product quantity and quality, many manufacturers rely on state-of-the-art machines and equipment. The latest offering from a global manufacturing equipment supplier is a top-of-the-line automated system that is sure to revolutionize production processes and deliver unparalleled levels of excellence.With over 40 years of experience in the industry, the company is a leader in the manufacturing equipment market. With a commitment to delivering the latest and most advanced technology, the company has made it their mission to stay ahead of the curve and provide customers with the tools they need to succeed. Their latest release is a fully automated system that is designed to optimize production processes for a variety of applications.The new system boasts a range of impressive features, including advanced material handling capabilities, precise controls, and customizable options to meet specific production needs. Capable of handling different materials and sizes, the automated system is built to deliver consistent and repeatable results, with minimal operator involvement. This allows for reduced waste, increased productivity, and enhanced employee safety.One of the most impressive aspects of the system is its ease of use. With user-friendly interfaces and intuitive controls, operators can quickly and easily adjust settings to accommodate varying production needs. The system also features a comprehensive monitoring system, enabling operators to track production progress and identify potential issues in real-time. This ensures that any issues that arise can be quickly addressed, minimizing downtime and maximizing efficiency.The automation system is particularly well-suited for applications where precision, consistency, and speed are critical. These include industries such as medical device manufacturing, electronics, and automotive production. The versatility of the system also makes it ideal for other applications, including food and beverage production, packaging, and logistics.In addition to the system's features, the company's customer service is known for being top-notch. With a team of highly skilled engineers and technical support professionals, customers can rely on them for unparalleled expertise and support. Their commitment to providing the highest level of support and assistance ensures that customers are always in good hands.The release of the new automation system is sure to have a significant impact on the industry. Its advanced features and versatility make it an excellent addition to any manufacturing operation, regardless of industry or product. The system's ability to optimize production processes, reduce waste, and increase employee safety makes it an attractive option for companies looking to streamline their operations and improve their bottom line.In conclusion, the release of the advanced automated system by the global equipment supplier marks a new era in manufacturing. With its advanced capabilities and user-friendly design, the system is sure to have a significant impact on the industry and make waves among manufacturers looking to stay ahead of the competition. With its commitment to innovation and customer service, the company is poised to continue leading the way in delivering the most advanced technology and equipment for the manufacturing industry.

Leading Manufacturers and Suppliers of Co2 Laser Machines for Marking, Cutting, and CNC Applications in China

Co2 Laser CNC Machine: The Cutting-Edge Technology in ManufacturingWith the continuous advancement of technology, manufacturing companies are faced with the challenge of coming up with more efficient and precise fabrication processes. Traditional methods of cutting and engraving materials are becoming obsolete, as they require manual labor and produce low-quality results. In this age of automation, it’s not surprising that Co2 Laser CNC Machine has emerged as the most innovative and modern way of achieving top-notch precision in cutting, engraving, and marking various materials.Co2 Laser CNC Machines have been gaining a lot of popularity in recent years due to their ability to perform complex tasks with high accuracy and speed. CNC stands for Computer Numerical Control, which means that the machine is operated by a computer that uses software to control its movements and directions. Co2 lasers, on the other hand, use Carbon Dioxide gas to produce incredibly powerful laser beams that can cut through thick materials with ease.The Co2 Laser CNC Machine technology offers several advantages over traditional methods of cutting and engraving. Foremost is its speed, which is significantly faster than any other cutting technology. It’s also more precise, with a laser beam width of less than 0.1mm, and produces fewer scraps since it uses a focused beam to make clean and precise cuts in materials.Another advantage of Co2 Laser CNC Machines is its versatility. These machines can cut and engrave materials such as wood, acrylic, leather, glass, plastic, and even metals. With their precision, they can create intricate designs that would be difficult to accomplish by hand or with traditional machines.Co2 Laser CNC Machines can also be custom-made to meet particular manufacturing needs. Whether for batch production or single piece projects, these machines can be programmed to execute a specific task, ensuring that each workpiece is of uniform quality. Additionally, they can be integrated with other automation technologies, such as robotics and sensors, to increase productivity and reduce labor costs.Finally, unlike other cutting and engraving methods, the Co2 Laser CNC Machine technology is eco-friendly. Since they use a laser beam instead of physical blades, for instance, there is no need to change blades frequently, therefore reducing waste and making them environmentally sustainable.ConclusionIn conclusion, Co2 Laser CNC Machine technology has revolutionized the manufacturing industry by providing an incredibly efficient and precise way of cutting, engraving, and marking various materials. The versatility, speed, precision, and eco-friendliness of these machines make them a must-have for any manufacturing company looking to stay ahead of the competition. There are many types of Co2 Laser CNC Machine available in the market, and selecting the right one for your need is critical. Therefore, we recommend that you consult with an experienced and reputable supplier of Co2 Laser CNC Machine to guide you in selecting the best-fit technology for your business.

High-Performance Fiber Cutting Machine for Precision Cutting

Fiber Cutting Machine Revolutionizing Material ProcessingIn today's fast-paced manufacturing industry, the demand for efficient and precise material processing solutions is higher than ever. As companies strive to improve productivity and reduce operational costs, the need for advanced cutting technology has become increasingly prevalent. One company at the forefront of this cutting-edge technology is {Company}, an industry leader in fiber cutting machines.{Company} is a global company with a proven track record of delivering high-quality, innovative solutions for a wide range of industries. With a focus on research and development, the company has consistently pushed the boundaries of what is possible in the field of material processing. Their dedication to providing cutting-edge technology has made them a trusted partner for businesses seeking to improve their manufacturing processes.The latest innovation from {Company} is the Fiber Cutting Machine, a state-of-the-art solution that is revolutionizing the way materials are processed. This cutting-edge machine is equipped with advanced features that set it apart from traditional cutting equipment, making it the ideal choice for businesses looking to improve efficiency and accuracy in their operations.One of the key features of the Fiber Cutting Machine is its ability to cut a wide range of materials with exceptional precision. Whether it is metal, plastic, or composite materials, this machine can handle them all with ease. The high-speed cutting capabilities of the machine ensure that productivity is maximized, allowing businesses to meet tight deadlines and improve overall efficiency.In addition to its cutting capabilities, the Fiber Cutting Machine also boasts a user-friendly interface that makes it easy to operate. This intuitive design minimizes the need for extensive training, allowing businesses to integrate the machine into their operations quickly and efficiently. This ease of use is coupled with advanced safety features, ensuring that operators can work confidently without compromising their well-being.Furthermore, the Fiber Cutting Machine's advanced software enables businesses to program complex cutting patterns with ease. This level of customization allows for greater flexibility in the manufacturing process, allowing businesses to meet the unique needs of their customers without compromising on quality.With sustainability becoming an increasingly important consideration for businesses, the Fiber Cutting Machine also excels in this area. By minimizing material waste and maximizing efficiency, businesses can reduce their environmental impact while improving their bottom line. This commitment to sustainability is a testament to {Company}'s dedication to delivering solutions that not only benefit businesses but also the world around us.As businesses across various industries continue to seek ways to improve their operations, the Fiber Cutting Machine from {Company} has emerged as a game-changer. Its advanced capabilities, user-friendly design, and commitment to sustainability make it the ideal choice for businesses looking to push the boundaries of material processing.As {Company} continues to innovate and expand its product offerings, their Fiber Cutting Machine stands as a testament to their dedication to delivering cutting-edge solutions for the manufacturing industry. With a proven track record of excellence and a commitment to pushing the boundaries of what is possible, it is no wonder that {Company} is recognized as a leader in the field of material processing technology.In conclusion, the Fiber Cutting Machine from {Company} represents a significant leap forward in the field of material processing. As businesses seek to improve their operations and meet the demands of a rapidly evolving market, this cutting-edge machine has emerged as a solution that delivers on all fronts. With its advanced capabilities, user-friendly design, and commitment to sustainability, the Fiber Cutting Machine is poised to revolutionize the manufacturing industry.

Understanding the Different Classes of Lasers for Safe Use

Laser Classification System Enhances Safety and Productivity Across IndustriesLasers are used in a variety of industries for tasks ranging from cutting and welding to marking and engraving. Though these devices have proven remarkably useful in a vast array of applications, they also present potential dangers to human beings and the environment. Laser Classification is an important aspect to ensure safety in workplaces, especially in industries that rely heavily on lasers.Laser Classification involves the categorization of lasers into different classes based on their potential dangers, with each class assigned its own set of safety guidelines and requirements. Class 1 lasers present no hazard, while Class 2 lasers are low-power and can cause eye damage if viewed directly for extended periods without eye protection. Class 3 and 4 lasers, on the other hand, pose significant risks, such as skin and eye injuries, burns and potential fire hazards. The proper classification of laser devices is essential to ensure the safety of people and effective operation of such equipment in the workplace.A leading provider of laser technology has introduced a comprehensive Laser Classification System, designed to enhance workplace safety, productivity, and regulatory compliance in a broad range of industries. The company's LCD touch-screen interface and automated software system classify the laser, ensuring that the device is being used safely and in compliance with regulatory guidelines."We understand the importance of providing our customers with safe, efficient, and reliable laser technology," said the company's CEO. "With our new Laser Classification System, we are not only ensuring safety, but we are also streamlining the entire classification process, allowing our customers to focus on their critical applications."The system automatically performs a series of tests, including measurement of output power, wavelength, pulse duration, and beam divergence, to accurately measure the laser's safety classification. Based on the results, the system assigns the appropriate classification according to the international safety standards and regulations, saving time and reducing the likelihood of human error in the classification process.In addition to offering a more efficient classification process, the system provides access to detailed reports and data, including the laser's classification and specifications. The data is automatically stored and can be easily retrieved for auditing and regulatory compliance purposes. This not only simplifies the classification process but also makes it easier to maintain safety records and facilitate the disposal or reclassification of devices when necessary.The Laser Classification System has been well-received by professionals across multiple industries, from aerospace to medical device manufacturing. In the aerospace industry, lasers are used for cutting and welding aircraft components and structures. With the implementation of the Laser Classification System, engineers and technicians can now work with confidence knowing that their laser devices are properly classified and safe to use. "The new system has made laser classification much more user-friendly, and we are pleased to have our lasers registered and certified in compliance with international standards," said the operations manager of an aircraft components manufacturer. "This has significantly reduced our regulatory compliance workload and has streamlined our laser device inventory management."Likewise, in the medical device industry, lasers are used for a broad range of procedures, from cutting and ablating tissue to sealing blood vessels. Effective laser classification is essential to ensuring the safety of patients and the healthcare professionals who use the devices. With the Laser Classification System in place, medical device manufacturers can now ensure that their laser products are properly classified in accordance with the international safety regulations.In conclusion, the introduction of Laser Classification System by a leading provider of laser technology is a significant achievement, providing reassurance to industries that rely on lasers that they are using this equipment safely and in compliance with regulations. This automation of the laser classification process not only simplifies it but also enhances workplace safety, productivity, and regulatory compliance across multiple industries. The Laser Classification System is an example of how technology can solve existing problems and create a safer working environment for professionals.

Explore Laser Engravers in Belleville Area - Shop, Sell, or Trade Now on Local Classifieds

When it comes to creating intricate designs or personalized gifts, a laser engraver can be a game-changer. These machines allow you to etch your designs onto a variety of materials quickly and easily. If you're in the market for a laser engraver, the Belleville Area has got you covered with its vast offerings on Kijiji's local classifieds. When choosing a laser engraver, one important factor to consider is its power. A 80w Co2 laser engraver is an excellent choice for those looking to tackle a wide range of materials such as wood, acrylic, and even stainless steel. Its high-powered beam allows for precise and deep engraving, making it ideal for commercial use. But it's not just for businesses - hobbyists and DIY enthusiasts can also benefit from owning a 80w Co2 laser engraver. It opens up endless possibilities for personalized creations such as custom signs, jewelry, and even leather goods. With a bit of creativity, the sky's the limit with what you can accomplish with this powerful machine. If you're worried about the cost of a new laser engraver, consider browsing Kijiji for used options. Many sellers offer high-quality machines that have been gently used and maintained for a fraction of the cost of a new one. Plus, by buying locally, you can save on shipping costs and potentially even get a chance to see the machine in action before making your purchase. In conclusion, a 80w Co2 laser engraver is a fantastic investment for anyone looking to add a new dimension to their creative endeavors. Whether you're a business owner or a DIY enthusiast, the versatility and power of this machine make it a must-have tool. Be sure to check out Kijiji's local classifieds in the Belleville Area to find the perfect laser engraver for your needs.

Efficient Laser Machine for Precise Gold Cutting: Top Features Your Business Needs to Look For

Title: Industry-Leading Gold Cutting Laser Machine Revolutionizes Jewelry ManufacturingIntroduction:In a groundbreaking development for the jewelry manufacturing industry, a pioneering company, known for its excellence in laser technology, has introduced the latest version of its Gold Cutting Laser Machine. This state-of-the-art equipment encompasses cutting-edge features and precision, poised to transform the way jewelry is manufactured. Equipped with advanced optics and intelligent software, it promises to streamline production processes while maintaining impeccable quality standards. This revolutionary addition to the company's portfolio is set to redefine the future of gold jewelry production globally.Paragraph 1:The Gold Cutting Laser Machine is the result of years of research and development by the renowned laser technology experts at [Company Name]. By combining their extensive knowledge of laser machinery with an in-depth understanding of the jewelry manufacturing industry, [Company Name] has designed a cutting-edge product that addresses the complexities and demands of this sector. This machine ensures high precision and accuracy during the intricate gold cutting process, allowing jewelry designers and manufacturers to create intricate and delicate patterns effortlessly.Paragraph 2:At the core of this revolutionary machine lies its advanced optics system, which guarantees unparalleled efficacy in gold cutting. The laser beam emitted by the machine is focused to an incredibly small point size, enabling precise and intricate cuts on gold sheets or blanks. Whether creating unique designs or replicating complex patterns, the machine produces flawless results with minimal material loss, saving both time and cost for manufacturers. This cutting-edge technology eliminates the need for traditional jewelry manufacturing techniques, such as sawing or hand cutting, thus boosting overall efficiency and productivity.Paragraph 3:To further enhance the machine's capabilities, [Company Name] has integrated intelligent software that seamlessly integrates with existing design software used by jewelry designers. This software enables users to import their digital designs directly into the machine, ensuring a precise replication of the pattern onto the gold surface. The Gold Cutting Laser Machine's software accurately interprets the intricate details of the design, making it possible to create highly customized and unique jewelry pieces that were previously challenging to manufacture manually.Paragraph 4:Moreover, this innovative machine supports a wide range of gold thicknesses, providing manufacturers with greater flexibility and adaptability. The machine's automatic thickness detection feature ensures optimal settings for every gold sheet, saving time that would otherwise be spent calibrating the machine for each piece. The Gold Cutting Laser Machine maintains consistent cutting quality across various gold thicknesses, granting jewelry manufacturers increased confidence and eliminating production inconsistencies.Paragraph 5:Safety has been a major consideration during the development of the Gold Cutting Laser Machine. Incorporating rigorous safety measures and protocols, this equipment ensures both operator and machine safety. With features such as automated shut-off mechanisms, real-time monitoring of the cutting process, temperature sensors, and fire suppression systems, [Company Name] has prioritized the well-being of its users while maintaining utmost precision and efficiency during production.Conclusion:The introduction of the Gold Cutting Laser Machine by [Company Name] marks a significant milestone in the jewelry manufacturing industry. With its breakthrough technology, advanced optics system, intelligent software, and emphasis on safety, this state-of-the-art machine is set to revolutionize the way gold jewelry is cut and manufactured. Offering unmatched precision, efficiency, and customization options, [Company Name] continues to push the boundaries of laser technology, facilitating the creation of exquisite jewelry that exceeds customer expectations worldwide.

Wholesale Industrial Ultrasonic Cleaner for Large-Scale Saw Blade Cutter Cleaning in China

and Suppliers, Industrial Ultrasonic Cleaner, Saw Blade Cutter Cleaning, 135L Large Capacity Ultrasonic Cleaner, Wholesale Ultrasonic Cleaner, Factory Direct Ultrasonic Cleaner.Industrial processes are often associated with a lot of dirt and greasy residue that needs to be cleaned up. However, cleaning such surfaces manually can be a cumbersome and time-consuming task, especially if it involves cutting tools like saw blades. That’s where industrial ultrasonic cleaners come in handy. These machines use ultrasonic cavitation to effectively clean cutting tools and other industrial surfaces without causing any damage.One such industrial ultrasonic cleaner designed for large saw blade cutter cleaning tasks is the 135L large capacity industrial ultrasonic cleaner. This 135-litre ultrasonic cleaner is manufactured by leading blade cleaner manufacturers and suppliers in China, and it is built to handle industrial cleaning tasks with outstanding efficiency. One of the standout features of this industrial ultrasonic cleaner is its large capacity. This attribute makes it well-suited for cleaning larger cutting tools that may require submersion in order to clean effectively. Additionally, the ultrasonic cavitation generated by this machine ensures that the entire cutting blade is thoroughly cleaned even at the microscopic level, eliminating any dirt or residue that could potentially cause performance issues. Furthermore, this machine is designed to be user friendly. It is equipped with a digital timer and temperature control system, making adjustments easy to navigate. In addition, its stainless steel construction ensures durability and longevity, and it is built with safety features to protect the operator. Buying this industrial ultrasonic cleaner from a wholesale ultrasonic cleaner supplier makes it even more affordable, as factory direct ultrasonic cleaners offer competitive pricing and access to reliable manufacturing support. Most reputable ultrasonic cleaner manufacturers and suppliers have been in the business for over a decade, and they have a proven track record of delivering high-quality machines that meet clients' needs. In conclusion, the 135L large capacity industrial ultrasonic cleaner for saw blade cutter cleaning is a highly effective cleaning solution that eliminates the tedious manual cleaning process for industrial surfaces, especially large cutting tools. With features like large capacity, superior cleaning capabilities, durability, and user-friendly controls, it is a machine that every industrialist should consider adding to their cleaning arsenal. So, the next time you need to clean your cutting tools and other industrial surfaces, consider investing in this versatile machine from a reputable blade cleaner manufacturer or supplier.

High Performance Fiber Laser Marking Machines with CE FDA Certification - Seeking Global Distributors

Fiber lasers have revolutionized the field of laser marking, and for good reason. These lasers offer a number of benefits over traditional marking methods, including faster processing speeds, higher resolution, and greater accuracy. If you are looking for a fiber laser marking machine, look no further than the DEK-10W/20W/30W/50W fiber laser marking machine from Jinan Dekcel CNC Equipment Co., Ltd.One of the biggest advantages of the DEK-10W/20W/30W/50W fiber laser marking machine is its speed. These machines can mark up to 10,000 mm/s, allowing you to complete your projects faster than ever before. They are also highly accurate, ensuring that each mark is clean and precise.The DEK-10W/20W/30W/50W fiber laser marking machines are also incredibly versatile, with the ability to mark a variety of materials including metals, plastics, and ceramics. This makes them an ideal choice for a wide range of applications, from engraving serial numbers on electronic components to adding logos to promotional products.In addition to their performance capabilities, the DEK-10W/20W/30W/50W fiber laser marking machines are also very user-friendly. They feature an intuitive interface and are easy to set up and use, even for those with little experience in laser marking technology.Of course, safety is always a top priority when working with lasers, and the DEK-10W/20W/30W/50W fiber laser marking machines are no exception. They come equipped with a number of safety features, such as automatic shut-off if the machine encounters an obstacle or if the temperature exceeds a certain level.Finally, it is worth noting that the DEK-10W/20W/30W/50W fiber laser marking machines are CE and FDA certified, ensuring that they meet rigorous safety standards and are suitable for use in a variety of settings.Overall, if you are in the market for a fiber laser marking machine, the DEK-10W/20W/30W/50W from Jinan Dekcel CNC Equipment Co., Ltd is an excellent choice. With its blazing fast speed, superior accuracy, and user-friendly interface, this machine is sure to be a valuable addition to your arsenal of marking tools.

High-Quality Metal Cutting Machinery for OEM Applications

OEM Metal Cutting Machinery, a leading manufacturer of high-quality metal cutting equipment, continues to make strides in the industry by providing cutting-edge solutions for a wide range of metal cutting applications. With a strong emphasis on innovation, reliability, and customer satisfaction, OEM Metal Cutting Machinery has become a trusted name in the manufacturing sector.Founded in [year], OEM Metal Cutting Machinery has built a solid reputation for delivering top-of-the-line metal cutting equipment to industries such as automotive, aerospace, energy, construction, and more. The company takes great pride in its ability to design and manufacture state-of-the-art machinery that meets the evolving needs of modern manufacturing.OEM Metal Cutting Machinery's commitment to excellence is evident in its extensive product line, which includes a variety of cutting machines such as CNC plasma cutters, laser cutting systems, waterjet cutters, and more. These machines are designed to deliver precision, speed, and efficiency, allowing manufacturers to achieve superior results in their metal cutting processes.In addition to its cutting-edge equipment, OEM Metal Cutting Machinery offers a range of services to support its customers, including installation, training, and technical support. The company's team of skilled technicians and engineers are dedicated to ensuring that customers receive the highest level of service and assistance in using their machinery effectively.One of the key factors that sets OEM Metal Cutting Machinery apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and incorporate the latest technological advancements into its products. This ensures that customers have access to the most advanced and efficient metal cutting solutions on the market.Moreover, OEM Metal Cutting Machinery is known for its focus on quality and reliability. Each machine is manufactured using the highest quality components and undergoes rigorous testing to ensure that it meets the company's strict quality standards. This attention to detail and dedication to producing reliable machinery has earned OEM Metal Cutting Machinery the trust and loyalty of its customers.Furthermore, sustainability is a key priority for OEM Metal Cutting Machinery. The company is committed to minimizing its environmental impact by implementing eco-friendly practices in its manufacturing processes and reducing energy consumption. This dedication to sustainability not only benefits the environment but also demonstrates OEM Metal Cutting Machinery's commitment to responsible and ethical business practices.As the manufacturing industry continues to evolve, OEM Metal Cutting Machinery remains at the forefront of innovation, consistently pushing the boundaries of what is possible in metal cutting technology. The company's ongoing investment in research, development, and customer support ensures that it is well-positioned to meet the evolving needs of manufacturers around the world.In conclusion, OEM Metal Cutting Machinery has established itself as a leader in the metal cutting machinery industry, thanks to its unwavering commitment to innovation, quality, reliability, and customer satisfaction. With a diverse range of cutting machines, exceptional service and support, a focus on sustainability, and a dedication to continuous improvement, OEM Metal Cutting Machinery continues to set the standard for excellence in the manufacturing sector.

Laser Cutting: Unveiling Innovations in Teaching, Learning, and Research

Title: Advancing Research and Possibilities: The Power of Laser Cutting[City], [Date] - Laser cutting technology has been making waves across various industries, revolutionizing manufacturing and design capabilities. The science behind precision cutting has found its way into the hallowed halls of Harvard University, with researchers harnessing its power to push boundaries in teaching, learning, and research. This breakthrough application represents a pivotal moment in the convergence of innovation and education.A collaboration between Harvard University and Cutting Laser Cutting, an industry-leading company specializing in laser cutting solutions, is enabling researchers at Harvard to explore new frontiers. With the ability to precisely cut through a variety of materials, including metal, wood, plastic, and fabric, laser cutting technology has opened up countless possibilities for innovation.Harvard's commitment to cutting-edge research and education has always been at the forefront. By utilizing laser cutting technology, the university aims to elevate its renowned programs even further, empowering students and faculty to explore new dimensions of creativity and problem-solving.One of the key areas where laser cutting is making a significant impact is in the field of engineering. By integrating this technology into the curriculum, Harvard is preparing its students for a future that demands proficiency in both traditional and advanced manufacturing techniques. Students can now witness firsthand the transformative power of precision cutting, incorporating it into their projects and research to push boundaries and achieve breakthroughs.Laser cutting also has the potential to revolutionize the world of art and design. With its remarkable precision and versatility, laser cutting enables artists and designers to bring their visions to life with unparalleled intricacy. By providing students and faculty access to state-of-the-art laser cutting technology, Harvard ensures that the artistic community within its walls remains at the forefront of innovative design and expression.Moreover, the collaboration with Cutting Laser Cutting allows Harvard researchers and scholars to delve deeper into their respective fields of study. Laser cutting technology facilitates intricate experiments, precise fabrications, and customized creations that were once unimaginable. The ability to manipulate materials with such precision serves as a catalyst for groundbreaking discoveries across various disciplines, including physics, biology, architecture, and more.In addition to its educational applications, laser cutting also holds immense potential for entrepreneurial endeavors. Harvard recognizes that the rapidly advancing field of laser cutting has given rise to new business opportunities. By equipping students with the knowledge and skills to harness this technology, the university is nurturing a generation of innovators and entrepreneurs who can spearhead industries of the future.With this collaboration, Harvard aims to further cement its position as a leading institution in promoting interdisciplinary collaboration. By joining forces with Cutting Laser Cutting, the university fosters mutually beneficial relationships with industry leaders, establishing a platform for ongoing research, development, and innovation.As the world adapts to an increasingly interconnected and technology-dependent landscape, Harvard University continues to evolve its teaching, learning, and research methodologies. Through the incorporation of laser cutting technology, the institution strengthens its commitment to preparing students for the challenges and opportunities of the future.Harnessing the power of laser cutting technology, Harvard University is not only shaping the minds of tomorrow's leaders but also pioneering advancements that have the potential to transform industries and society as a whole. The partnership with Cutting Laser Cutting marks a significant milestone in the convergence of academia and technology, propelling Harvard's renowned programs and research to even greater heights.