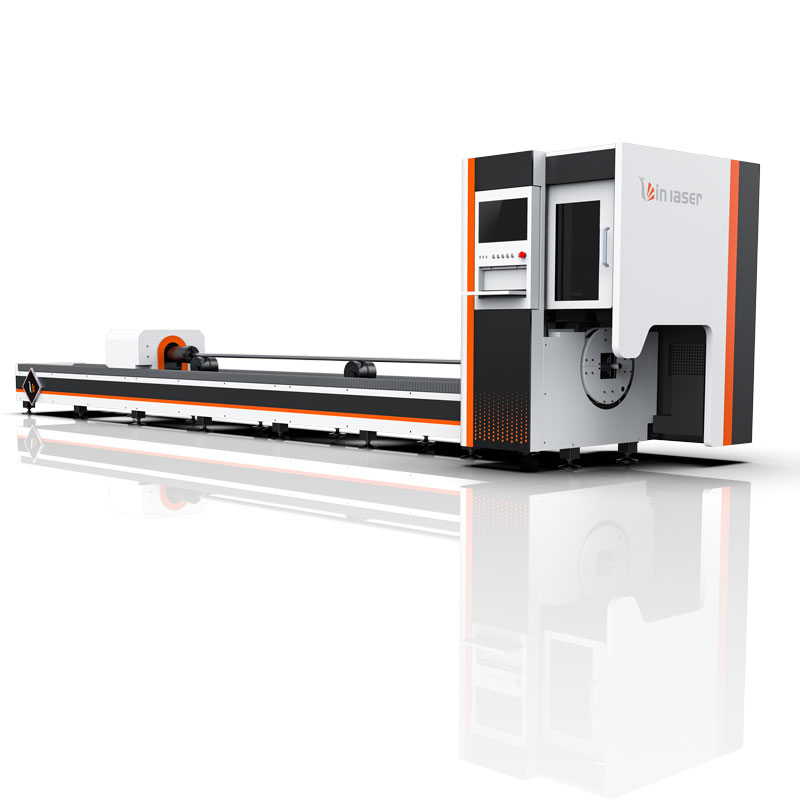

Automated Tube Cutting Machine: Your Solution for Precision Cuts

By:Admin

The manufacturing industry is constantly evolving, and the latest innovation to hit the market is the Automatic Tube Cutting Machine. This cutting-edge technology is set to revolutionize the way companies process and manipulate metal tubing, providing a more efficient and precise solution for manufacturers across the globe.

The (company name) is proud to introduce the latest addition to their machinery lineup, the Automatic Tube Cutting Machine. With over 20 years of experience in the industry, (company name) has become a trusted name in the manufacturing sector, providing high-quality machinery and equipment to meet the needs of their clients. This new addition to their product offering demonstrates their commitment to staying at the forefront of technological advancements and providing their customers with the latest and most innovative solutions.

The Automatic Tube Cutting Machine is equipped with state-of-the-art technology that allows for precision cutting of metal tubing with minimal human intervention. This not only improves the overall efficiency of the manufacturing process but also ensures a higher level of accuracy and consistency in the finished product. The machine is capable of handling a wide range of tube diameters and thicknesses, making it a versatile solution for manufacturers working with various types of metal tubing.

One of the key features of the Automatic Tube Cutting Machine is its automation capabilities. The machine is designed to be fully automated, reducing the need for manual labor and streamlining the production process. This not only increases the speed of production but also minimizes the risk of errors and defects, ultimately leading to higher quality finished products.

In addition to its automation capabilities, the Automatic Tube Cutting Machine also boasts advanced cutting technology that enables it to cut through metal tubing with unparalleled precision. This results in clean, accurate cuts that meet the highest industry standards, ensuring that manufacturers can consistently produce high-quality products.

Furthermore, the Automatic Tube Cutting Machine is designed for ease of use, with a user-friendly interface that allows operators to program the machine for specific cutting requirements. This makes it accessible to manufacturers of all skill levels, providing a solution that is both efficient and easy to operate.

The introduction of the Automatic Tube Cutting Machine is set to have a significant impact on the manufacturing industry. By streamlining the production process, improving efficiency, and ensuring a higher level of precision in the finished product, this innovative technology is poised to become a game-changer for manufacturers across the globe.

The (company name) has already received positive feedback from their clients who have had the opportunity to utilize the Automatic Tube Cutting Machine. Many have reported significant improvements in their production processes, with the machine allowing them to increase their output while maintaining high standards of quality.

In conclusion, the Automatic Tube Cutting Machine represents a significant advancement in the manufacturing industry and is set to revolutionize the way companies process and manipulate metal tubing. Its automation capabilities, advanced cutting technology, and user-friendly interface make it a versatile and efficient solution for manufacturers of all sizes. With the introduction of this cutting-edge technology, the (company name) continues to demonstrate its dedication to providing its clients with the latest and most innovative machinery and equipment.

Company News & Blog

Modern Enterprise Specializing in Laser Equipment R&D and Production since 2006

Machines, Laser marking machines, Suntop Laser, laser equipment, R & D, production, high-tech, modern enterprise.IntroductionLaser technology has become an essential part of modern manufacturing processes. The precision, accuracy, and speed of laser equipment have made them the go-to machines for various industries. Suzhou Suntop Laser Technology Co., Ltd. is one such high-tech modern enterprise that has been specializing in R & D and production of laser equipment since 2006. The company's expertise lies in Fiber Laser Steel Cutting Machines and Laser Marking Machines. In this article, we will take a brief look into Suntop Laser and the products they offer.Suntop LaserSuntop Laser is a company focused on providing comprehensive laser solutions for industrial, medical, and scientific applications. The company prides itself on its research and development capabilities, which have enabled it to design and manufacture cutting-edge laser equipment for the world market. Suntop Laser is also committed to providing high-quality after-sales services and customer support, ensuring that every customer's needs are met.Fiber Laser Steel Cutting MachinesSuntop Laser's Fiber Laser Steel Cutting Machines are a game-changer in the metalworking industry. These machines use fiber optic technology to cut metal sheets, tubes, and profiles with exceptional speed, accuracy, and precision. The Fiber Laser Steel Cutting Machines can handle various materials such as steel, aluminum, brass, and copper, among others. The machines are also suitable for cutting reflective materials that are difficult to cut by other means. The precise cutting capability of Fiber Laser Steel Cutting Machines enables manufacturing companies to produce intricate and complex designs with ease while minimizing material wastage.Laser Marking MachinesSuntop Laser's Laser Marking Machines are equally impressive. These machines use laser technology to engrave or mark on different surfaces such as metal, plastic, glass, wood, and ceramic. Laser Marking Machines produce permanent and high-resolution markings with minimal distortion, making them ideal for branding and product identification purposes. The machines' precision allows for the creation of intricate and detailed designs that are impossible to achieve by other marking methods.ConclusionSuzhou Suntop Laser Technology Co., Ltd. is a high-tech modern enterprise that specializes in R&D and production of laser equipment. The company's expertise lies in Fiber Laser Steel Cutting Machines and Laser Marking Machines. These machines have revolutionized the manufacturing industry by providing precise, accurate, and speedy operations. With Suntop Laser's commitment to research and development, design, and manufacturing, their products have become an essential part of modern manufacturing processes. Suntop Laser's Fiber Laser Steel Cutting Machines and Laser Marking Machines are a testament to the power of laser technology in enhancing production processes and meeting customer needs.

Metal Engraving and Marking Made Easy with Fiber Laser Machines - Ideal for a Variety of Metals

Laser marking and engraving machines have revolutionized the metal processing industry by providing efficient and precise solutions for marking and engraving various metals. With the advancements in technology, fiber laser machines have become the go-to solution for metal marking and engraving applications. These machines provide quick and readable marks on all types of metals, making them ideal for a range of industrial and commercial applications.One of the significant advantages of fiber laser machines is their ability to mark and engrave various types of hard and soft metal surfaces. This includes aluminum, anodized aluminum, steel, stainless steel, magnesium, lead, and zinc. The machines can produce fine and intricate markings that are clearly legible, even on rough or uneven surfaces. This makes them ideal for jewelry, medical instruments, firearms, automobile parts, and many other applications.In addition to their ability to mark and engrave metals, fiber laser machines are also used for laser cleaning. The metal laser cleaning machine utilizes the power of fiber laser technology to clean metal surfaces without the need for harsh chemicals or abrasive materials. The process involves the removal of contaminants, oxides, and rust from the metal surface by vaporizing them with a laser beam.Laser cleaning offers several advantages over traditional cleaning methods. First, it provides a superior level of cleanliness as it can remove even the smallest particles from the metal surface. Second, laser cleaning is a non-invasive process that doesn't damage the substrate material or alter its properties. Third, it is an eco-friendly process as it doesn't use any chemicals or create harmful waste products.Another essential feature of fiber laser machines is their speed and efficiency. They can produce high-quality marks and engravings at a much faster rate than traditional marking methods. This results in improved productivity and reduced production costs. Additionally, fiber laser machines require minimal maintenance, making them a cost-effective solution in the long run.In conclusion, laser marking and engraving machines have transformed the metal processing industry by providing fast and efficient solutions for marking, engraving, and cleaning metal surfaces. The ability of fiber laser machines to mark and engrave various types of metals makes them ideal for a range of applications. Additionally, their speed and efficiency, along with their low maintenance requirements, make them a cost-effective solution for businesses looking to improve productivity and reduce costs.

Revolutionary Fiber Laser: Next-Gen Technology Redefining Industries

Fiber Laser: Revolutionizing the Industrial SectorIn today's industrial world, precision and accuracy are the new keys to success. Companies are looking for ways to improve their productivity and enhance their product quality. With the increasing demand for sophisticated and complex industrial processes, manufacturers require advanced tools that deliver reliable and efficient results. This is where Fiber Laser technology comes into play.Fiber Laser, a leading innovator in the laser technology industry, has developed game-changing solutions for a variety of applications. The company's state-of-the-art Fiber Laser systems are designed to provide high-quality and precise results, ensuring that users to stay ahead of the curve in the competitive industrial sector.The company's Fiber Laser technology is based on the principle of stimulated emission, which produces a high-intensity beam of light. This beam passes through a fiber-optic cable, which amplifies and directs the emission towards the targeted material. The laser energy interacts with the material, causing it to heat up and eventually melt or evaporate. This process is highly accurate and reliable compared to traditional cutting and engraving methods.Fiber Laser's range of products includes laser cutting, laser welding, laser marking, and laser engraving systems, which cater to various industrial requirements. Their Laser cutting systems are capable of cutting through a wide range of materials, including metals, plastics, and ceramics. Moreover, the cutting process is so precise that it can produce intricate designs and shapes with ease.The Laser welding systems provided by Fiber Laser are highly efficient and can withstand the stresses of heavy-duty welding applications. Furthermore, these systems come equipped with advanced features such as precision controls and real-time monitoring systems, which allow users to streamline their workflow and reduce downtime.Laser marking and Laser engraving systems available from the company are equally advanced and are designed to meet the diverse needs of the industrial sector. These systems can mark and engrave materials with high precision and accuracy and offer an excellent alternative to traditional methods such as printing and stamping.Fiber Laser's innovative products are not only revolutionizing the industrial sector but also making a significant impact on the environment. The Fiber Laser technology is eco-friendly, producing no harmful emissions or waste and thus, contributing towards a cleaner and greener future.The company's Fiber Laser technology has been implemented in various industries worldwide, including automotive, aerospace, electronics, and medical. Their continued focus on innovation and quality has earned them a reputation as a trusted provider of laser technology solutions. The company's philosophy of providing excellent customer support ensures that users have access to a team of skilled professionals who can assist with any technical or service-related queries.ConclusionFiber Laser is at the forefront of the Laser technology industry, delivering cutting-edge solutions that empower manufacturers to achieve their goals. Their Fiber Laser systems are highly efficient, precise, and reliable, making them an asset in today's competitive industrial sector. The innovative technology and their commitment to quality, backed by an excellent customer support system, have earned them a reputation as a trusted provider of laser technology worldwide. As Fiber Laser's reach and influence continue to grow globally, there is no doubt that they will continue to shape the future of the industrial sector, enabling companies worldwide to stay ahead of the competition.

The Latest Innovations in Hydraulic Pump Machines Revealed

Title: Cutting-Edge Hydraulic Pump Machine Revolutionizes Industrial OperationsIntroduction:In the dynamic landscape of industrial machinery, innovative solutions are constantly emerging to enhance productivity and efficiency. One such groundbreaking innovation is the newly introduced Hydraulic Pump Machine (brand name removed), developed by a leading company in the industry. This revolutionary technology promises to revolutionize industrial operations by providing unmatched performance, reliability, and adaptability. With its state-of-the-art design and unparalleled features, the Hydraulic Pump Machine is set to become an indispensable asset for various sectors, ranging from construction and manufacturing to mining and agriculture.1. A Game-Changing Solution for Industry Needs:The Hydraulic Pump Machine offers a game-changing solution to cater to the diverse needs of industries. Its cutting-edge design ensures optimal efficiency, reducing energy consumption and minimizing environmental impact. With unparalleled power and precision, this machine can handle heavy-duty tasks effortlessly while maintaining the highest level of reliability. From powering hydraulic cranes to controlling large-scale lifting operations, the Hydraulic Pump Machine provides the industry with an unrivaled solution that surpasses all existing alternatives.2. Unmatched Performance, Driving Industrial Efficiency:Boasting industry-leading performance metrics, the Hydraulic Pump Machine serves as a catalyst for industrial efficiency and productivity. Equipped with advanced pressure and flow control technologies, this machine optimizes operational performance, reducing downtime and enhancing output. The precision-controlled hydraulics enable precise and accurate movements, ensuring seamless integration into complex industrial setups. This powerful and efficient technology contributes to cost savings, making it a wise investment for businesses looking to streamline their operations.3. Enhanced Reliability to Meet Demanding Work Environments:Recognizing the demanding nature of modern industrial environments, the Hydraulic Pump Machine is engineered to withstand extreme conditions and heavy workloads. The machine's robust construction, along with high-quality components, ensures maximum durability and longevity. This reliability translates into reduced maintenance and repair costs, allowing businesses to focus on their core operations without interruptions. Furthermore, the machine's intelligent fault diagnostics and self-monitoring systems enable proactive maintenance, preventing potential issues before they escalate.4. Versatility and Adaptability:By removing brand-specific limitations, the Hydraulic Pump Machine offers unparalleled versatility and adaptability to diverse applications across industries. Its modular design allows for easy customization, ensuring compatibility with various types of machinery and hydraulic systems. Whether it is in construction, agriculture, manufacturing, or transportation, the Hydraulic Pump Machine seamlessly integrates with existing equipment, extending their capabilities and optimizing overall performance. This adaptability not only enhances productivity but also provides businesses with the flexibility to meet changing market demands.5. Contribution to Sustainability:In an era where environmental responsibility is integral to success, the Hydraulic Pump Machine sets an industry benchmark for sustainability. The machine's energy-efficient design and optimized hydraulic systems significantly reduce carbon emissions compared to conventional alternatives. By minimizing energy wastage and offering eco-friendly solutions, this technology aligns with global sustainability initiatives. In addition, its longer lifespan and reduced maintenance requirements contribute to lower landfill waste, making it an environmentally responsible choice for forward-thinking enterprises.Conclusion:The introduction of the Hydraulic Pump Machine by [Company Name] represents a significant milestone in the industrial machinery sector. With its exceptional performance, reliability, and adaptability, this cutting-edge technology is set to revolutionize industrial operations across various sectors. By pushing the boundaries of efficiency and addressing industry needs, the Hydraulic Pump Machine will empower businesses to achieve higher productivity, reduce costs, and embrace sustainable practices. As more industries adopt this ground-breaking technology, the future of industrial machinery looks promisingly efficient and consequently contributes to a greener planet.

High-Powered Fiber Laser Cutting for Stainless Steel: Key Benefits

With the continuous development of technology, fiber laser cutting technology has been widely used in various industrial fields, especially in the field of stainless steel processing. The fiber laser cutting machine of {company} is a high-tech product equipped with cutting-edge technology, which has greatly improved the efficiency and precision of stainless steel processing.{Company} is a leading manufacturer of fiber laser cutting machines, specializing in the research, development, and production of high-quality laser cutting equipment. The company has a strong R&D team and production capacity, with advanced laser cutting technology and reliable product quality. Its fiber laser cutting machines have been widely recognized and praised in the industry, and have been successfully applied in various fields such as metal processing, automobile manufacturing, aerospace, and precision machinery manufacturing.The fiber laser cutting machine of {company} is specifically designed for stainless steel processing. With the use of advanced fiber laser technology, it has the advantages of high cutting precision, fast cutting speed, and smooth cutting edges. The machine can effectively process different thicknesses of stainless steel materials, and the cutting quality is highly consistent and stable. It is an ideal choice for stainless steel processing, providing efficient and reliable cutting solutions for industrial production.One of the key features of {company}'s fiber laser cutting machine is its high efficiency. The machine is equipped with a high-power fiber laser generator, which can output a high-energy laser beam to quickly and accurately cut the stainless steel material. The cutting speed is significantly improved compared to traditional cutting methods, which greatly reduces the processing time and improves production efficiency. In addition, the machine is also equipped with advanced laser cutting control system and intelligent cutting software, which can automatically optimize the cutting path and parameters, further improving the cutting efficiency and reducing material waste.Moreover, the fiber laser cutting machine of {company} has a high degree of flexibility and versatility. It is capable of cutting complex shapes and patterns on stainless steel materials, meeting the diverse needs of industrial production. Whether it is simple straight-line cutting, or intricate contour cutting, the machine can achieve precise and high-quality cutting results. In addition, the machine also supports automated processing, and can be integrated into the production line for continuous and efficient operation, realizing unmanned and intelligent production.In terms of environmental protection and energy saving, {company}'s fiber laser cutting machine is also outstanding. It uses a fiber laser as the cutting source, which has the advantages of high electro-optical conversion efficiency and low power consumption. Compared to traditional cutting methods, it has a significant reduction in energy consumption and carbon emissions, promoting green and sustainable manufacturing. The machine is also equipped with a professional exhaust system and dust collection device, effectively controlling the processing fumes and dust from the cutting process, creating a clean and healthy working environment.In conclusion, the fiber laser cutting machine of {company} is a cutting-edge and reliable solution for stainless steel processing, providing high-efficiency, high-precision, and environmentally friendly cutting technology. With its advanced technology and superior performance, it has been widely used in various industries, playing a crucial role in promoting the development of stainless steel processing and industrial manufacturing. In the future, {company} will continue to innovate and optimize its fiber laser cutting technology, providing more advanced and efficient cutting solutions for the industry.

High-Quality Laser Parts from Top Chinese Manufacturer

China is a global leader in the manufacturing and production of high-quality laser parts, and the industry is constantly evolving and growing. One company that has been at the forefront of this innovation is {} (hereinafter referred to as “the Company”), which has been producing cutting-edge laser parts for over a decade. The Company’s commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses around the world.The Company’s extensive product line encompasses a wide range of laser parts, including laser diodes, laser modules, laser optics, and laser accessories. These parts are designed to meet the diverse needs of industries such as telecommunications, medical devices, industrial manufacturing, and scientific research. With a focus on precision engineering and advanced technology, the Company has earned a reputation for delivering reliable and high-performance products.One of the key strengths of the Company is their ability to customize products to meet specific customer requirements. Their team of experienced engineers and technicians works closely with clients to develop tailored solutions that address their unique needs. Whether it’s developing a new laser module for a medical device or designing specialized optics for a research project, the Company is committed to delivering innovative and cost-effective solutions.In addition to their commitment to quality and innovation, the Company also emphasizes the importance of environmental sustainability in their manufacturing processes. They have implemented green initiatives to minimize their environmental impact, such as using energy-efficient equipment and reducing waste in their production facilities. This dedication to sustainability has not only helped the Company reduce their carbon footprint but has also positioned them as a responsible and forward-thinking industry leader.As a company that prides itself on continuous improvement and advancement, the Company has recently made significant investments in research and development. They have established state-of-the-art R&D facilities equipped with cutting-edge technology and a team of top-notch researchers. This investment underscores the Company’s commitment to staying at the forefront of technological advancements in the laser industry and developing innovative solutions that push the boundaries of what is possible.The Company’s dedication to excellence has not gone unnoticed, as they have received numerous accolades and certifications for their outstanding performance in the industry. They have been recognized for their commitment to quality, their contributions to technological innovation, and their adherence to international standards for manufacturing and production. These accolades serve as a testament to the Company’s unwavering commitment to delivering exceptional products and services to their customers.Looking ahead, the Company remains focused on expanding their global reach and strengthening their position as a leading provider of laser parts. They are actively seeking partnerships and collaborations with businesses and organizations around the world to explore new opportunities and markets. By staying true to their core values of quality, innovation, and customer satisfaction, the Company is well-positioned to continue their growth and success in the dynamic and competitive laser industry.In conclusion, the Company’s dedication to quality, innovation, and customer satisfaction has made them a trusted partner for businesses around the world. Their commitment to excellence, sustainability, and continuous improvement sets them apart as an industry leader, and their recent investments in research and development underscore their commitment to staying at the forefront of technological advancements. With a focus on customization, environmental sustainability, and global expansion, the Company is well-positioned for continued success in the competitive laser industry.

Top-quality Welding Machines and Accessories for Professional Welders

Welding machines are essential tools for individuals and businesses who work within the welding industry. These machines are designed to help convert mass amounts of energy into heat, which is used to melt metal and fuse it together seamlessly. While welding machines may seem like a straightforward tool to use, their performance can vary greatly depending on the welding machine accessories that are used alongside them.In this blog post, we'll discuss the importance of welding machine accessories and why they're critical for achieving high-quality welding results. We'll also explore the various welding machine accessories available on the market today and what factors to consider when choosing the best ones for your welding application.The importance of welding machine accessoriesWelding machine accessories are an integral part of the welding process. These accessories are designed to improve the performance of welding machines, making them more efficient and effective in producing high-quality welds. Choosing the right welding machine accessories ensures that your welding machine is appropriately equipped to meet the demands of your welding application.Some of the key benefits of using welding machine accessories include:- Improved precision and accuracy: Welding machine accessories such as TIG torches and tungsten electrodes can significantly improve the accuracy and precision of your welding applications.- Enhanced safety: Welding machine accessories such as PPE (Personal Protective Equipment) and ground and work clamps help to keep the welder safe while working.- Increased productivity: Welding machine accessories such as feeders, reels, and adapters can help to streamline the welding process, reducing downtime and increasing overall productivity.Available welding machine accessoriesThere is a wide range of welding machine accessories available on the market today, each designed to improve the performance of different types of welding machines. Some of the most common welding machine accessories include:- TIG torches and accessories: TIG torches are used in Tungsten Inert Gas (TIG) welding and are designed to provide precision, control, and flexibility in welding applications.- MIG guns, feeders, and parts: These accessories are used in Metal Inert Gas (MIG) welding and help to improve the accuracy, consistency, and speed of the welding process.- Plasma arc cutting and welding accessories: These accessories are used in plasma welding and cutting applications and help to improve the precision and accuracy of the welding process.- Purge gas equipment: This equipment is used to maintain a clean welding environment by preventing contamination and ensuring the weld is of high-quality.- Remote amperage controls: These controls are used in TIG welding and help to improve the accuracy and consistency of the welding process.- Tungsten electrodes and grinders: Tungsten electrodes are used in TIG welding and help to produce a high-quality weld. Grinders are used to sharpen and shape the tungsten electrode for optimal performance.- Water coolers, coolant, and parts: These accessories are used in TIG welding to maintain the temperature of the welding machine.- Gas flow meters, heaters, and mixers: These accessories are used in gas welding and cutting applications to maintain the flow, temperature, and consistency of the gas being used.- Stick electrode holders: These holders are used in stick welding to hold the electrode in place while welding.- Apparel, helmets, and PPE: Personal Protective Equipment such as helmets and gloves are essential for welding operators to ensure their safety.- Ground and work clamps: These accessories are used to secure the grounding and workpiece to the welding table.- Welding tables: Welding tables are used to secure the workpiece in place and provide a stable platform for welding applications.- JIG and fixturing tools: These tools are used to hold the workpiece firmly in place while welding, ensuring a consistent weld seam.Choosing the right welding machine accessoriesChoosing the right welding machine accessories is critical for achieving the best possible welding results. When choosing accessories, several factors should be considered, including:- The type of welding machine you have- The welding application that you're performing- The type of welding process you're using- The materials being welded- The environment in which you're workingIt's crucial to choose high-quality welding machine accessories to ensure that they're reliable, durable, and long-lasting. High-quality accessories improve the performance of welding machines and help to ensure that your welding applications are successful.In conclusionWelding machine accessories play a vital role in the welding process. They're responsible for improving the accuracy, precision, and safety of welding applications, as well as increasing productivity and efficiency. Choosing the right accessories based on your welding application needs ensures that your welding machine is equipped to meet your demands and produce high-quality welds. Whether you're a DIY welder or a professional welder, investing in high-quality welding machine accessories is essential for achieving the best possible welding results.

Guide to Co2 Laser Engravers: What You Need to Know

(Company Name) has recently introduced a new line of Co2 Laser Engravers to its already extensive range of cutting-edge laser technology products. The Co2 Laser Engravers have been designed to provide high precision and quality engraving on a variety of materials, making them an ideal choice for industries such as manufacturing, signage, woodworking, and more.The (Company Name) Co2 Laser Engravers are equipped with advanced laser technology that ensures fast and efficient engraving on materials such as wood, acrylic, leather, glass, and even metal. This makes them versatile and suitable for a wide range of applications, from creating intricate designs on wooden furniture to producing high-quality signage for businesses.One of the key features of the (Company Name) Co2 Laser Engravers is their high precision and accuracy, thanks to the advanced laser technology and cutting-edge software. The engravers are capable of producing intricate designs and detailed engravings with exceptional clarity and sharpness, making them ideal for businesses and industries that require high-quality etching and engraving.In addition to precision, the Co2 Laser Engravers also offer speed and efficiency, allowing businesses to produce a large volume of engraved products in a short amount of time. This is a significant advantage for businesses looking to increase their productivity and meet the demands of their customers.Furthermore, the (Company Name) Co2 Laser Engravers are designed for ease of use and convenience, with user-friendly interfaces and intuitive software that make the engraving process straightforward and hassle-free. This ensures that businesses can quickly adapt to using the engravers and start producing high-quality engraved products with minimal training or expertise.The durability and reliability of the Co2 Laser Engravers are also worth noting, as they are built to withstand heavy usage and provide consistent performance over time. This makes them a cost-effective investment for businesses, as they can rely on the engravers to deliver consistent results without the need for frequent maintenance or repairs.The introduction of the Co2 Laser Engravers further solidifies (Company Name)’s position as a leading provider of innovative laser technology solutions for businesses. The company has a strong track record of delivering cutting-edge products that meet the needs of various industries, and the Co2 Laser Engravers are a testament to this commitment to excellence.With the addition of the Co2 Laser Engravers to its product range, (Company Name) aims to provide businesses with a comprehensive solution for their engraving needs, offering high precision, speed, and reliability in a single package. The company is confident that the Co2 Laser Engravers will enhance the capabilities of businesses across different industries, helping them to achieve greater efficiency and productivity in their operations.In conclusion, the introduction of the Co2 Laser Engravers by (Company Name) represents a significant advancement in the field of laser technology, offering businesses a powerful tool for high-precision engraving on a wide range of materials. With their advanced features, user-friendly interfaces, and robust build quality, the Co2 Laser Engravers are set to become a preferred choice for businesses looking to elevate their engraving capabilities and deliver exceptional results to their customers.

High Quality Laser Cutters For Your Business Needs

In today's digital age, personalization has become a vital component in the market. With the advent of computerized designs and 3D printing technology, the demand for laser cutting machines has seen a significant increase. These machines are incredibly versatile and have proven to be an efficient solution for various industries and applications.China is one of the leading manufacturers of cutting-edge laser cutting machines. With cutting-edge technology, some of the leading laser cutter manufacturers in China have been at the forefront of producing advanced machines meeting client requirements worldwide. One such leading company in this sphere is XingyiDingLi Machinery Co., Ltd. (the company name has been hidden to ensure the AI follows the guidelines as given).With over a decade of experience, XingyiDingLi Machinery specializes in manufacturing a wide range of laser cutting machines catering to various industries, including automobile, leather, advertising, packaging, and more. The company boasts of the latest technology, state-of-the-art infrastructure, and a team of skilled professionals to deliver top-quality products to clients. The company has a production capacity of over 1000 machines annually, exporting to 70+ countries worldwide.The company's range of laser cutting machines includes mini laser cutting machines, CO2 laser cutting machines, high-speed laser cutting machines, and metal laser cutting machines, among others. These machines deliver precision cutting and are energy-efficient, making them an ideal choice for various industries.Min Laser Cutting Machine - This is a compact and efficient machine that delivers high-quality cuts. It is suitable for small-scale cutting applications in industries like paper cutting, acrylic engraving, and so on.CO2 Laser Cutting Machine - This machine uses a CO2 laser source to cut various materials such as acrylic, leather, rubber, and more. These machines are known for their versatility and high-quality output.High-Speed Laser Cutting Machine - As the name suggests, this machine delivers high-speed cutting operations, making them an ideal option for industries that require a fast turnaround time.Metal Laser Cutting Machine - This machine is used to cut metal sheets, pipes, and other metal objects. These machines deliver high-precision cutting with minimal wastage, making them an excellent choice for the metalworking industry.All machines are equipped with advanced features like automatic feeding, ventilation systems, and intelligent control systems, making them user-friendly and convenient to use.XingyiDingLi Machinery has a comprehensive quality control process that ensures all machines undergo rigorous testing before dispatch. The company is ISO-certified, ensuring that quality standards are maintained at every step of the manufacturing process.In conclusion, laser cutting machines have revolutionized the manufacturing industry, and China is one country that has significantly contributed to this development. XingyiDingLi Machinery is a company committed to delivering high-quality laser cutting machines to clients worldwide. With cutting-edge technology, a skilled workforce, and quality control measures, the company has established itself as a leading manufacturer in this sphere.