How Fiber Laser Cutting Systems Are Improving Manufacturing Processes

By:Admin

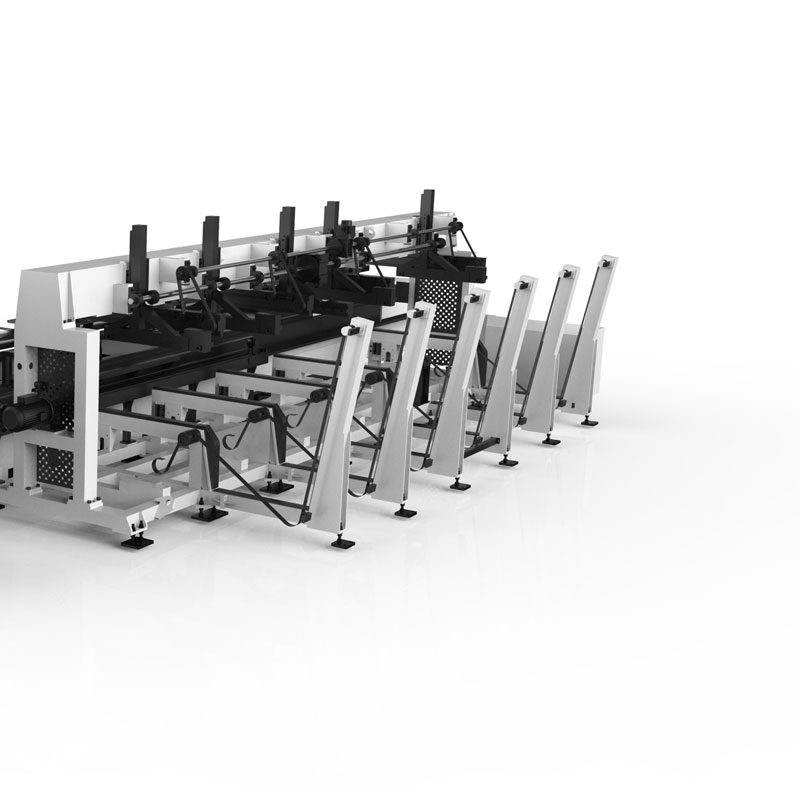

The {Company X} Fiber Laser Cutting Systems are equipped with state-of-the-art technology that allows for fast and accurate cutting of a wide range of materials, including stainless steel, aluminum, copper, and titanium. These cutting systems are designed to meet the needs of various industries, from automotive and aerospace to medical and consumer electronics.

One of the key features of {Company X} Fiber Laser Cutting Systems is their high precision, which is made possible by advanced motion control systems and intelligent software. This level of precision ensures that the finished parts meet the strictest quality standards, making them ideal for use in the most demanding applications.

In addition to precision, {Company X} Fiber Laser Cutting Systems are known for their speed and efficiency. With high-powered laser sources and high-speed cutting heads, these machines can quickly and accurately cut complex shapes and intricate patterns, reducing production time and increasing overall productivity.

Furthermore, {Company X} offers a range of Fiber Laser Cutting Systems to suit different production needs, from small, compact machines for smaller workshops to large, automated systems for high-volume production facilities. This flexibility makes {Company X} a preferred choice for businesses of all sizes, seeking to enhance their metal cutting capabilities.

{Company X} not only provides cutting-edge machines but also offers comprehensive support and services to ensure that their customers get the most out of their investment. This includes training programs, maintenance services, and technical support, all aimed at keeping the Fiber Laser Cutting Systems running at peak performance.

With a strong commitment to research and development, {Company X} is constantly pushing the boundaries of what is possible with Fiber Laser Cutting technology. Their team of engineers and technicians are always working on new innovations and improvements to further enhance the capabilities of their cutting systems, staying ahead of the curve and setting new industry standards.

Through strategic partnerships and collaborations with other industry leaders, {Company X} continues to drive the advancement of Fiber Laser Cutting technology, ensuring that their customers have access to the latest and most advanced solutions for their metal cutting needs.

In conclusion, {Company X} Fiber Laser Cutting Systems are setting new benchmarks in the metal cutting industry, providing unmatched precision, speed, and efficiency to a wide range of businesses. With a strong focus on innovation, customer satisfaction, and comprehensive support, {Company X} remains a trusted partner for those seeking to elevate their metal cutting capabilities. As the demand for high-quality, precision-cut parts continues to grow across various industries, {Company X} is well-positioned to meet and exceed these demands with their cutting-edge technology and unwavering commitment to excellence.

Company News & Blog

High-Quality Metal Cutting Machinery for OEM Applications

OEM Metal Cutting Machinery, a leading manufacturer of high-quality metal cutting equipment, continues to make strides in the industry by providing cutting-edge solutions for a wide range of metal cutting applications. With a strong emphasis on innovation, reliability, and customer satisfaction, OEM Metal Cutting Machinery has become a trusted name in the manufacturing sector.Founded in [year], OEM Metal Cutting Machinery has built a solid reputation for delivering top-of-the-line metal cutting equipment to industries such as automotive, aerospace, energy, construction, and more. The company takes great pride in its ability to design and manufacture state-of-the-art machinery that meets the evolving needs of modern manufacturing.OEM Metal Cutting Machinery's commitment to excellence is evident in its extensive product line, which includes a variety of cutting machines such as CNC plasma cutters, laser cutting systems, waterjet cutters, and more. These machines are designed to deliver precision, speed, and efficiency, allowing manufacturers to achieve superior results in their metal cutting processes.In addition to its cutting-edge equipment, OEM Metal Cutting Machinery offers a range of services to support its customers, including installation, training, and technical support. The company's team of skilled technicians and engineers are dedicated to ensuring that customers receive the highest level of service and assistance in using their machinery effectively.One of the key factors that sets OEM Metal Cutting Machinery apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and incorporate the latest technological advancements into its products. This ensures that customers have access to the most advanced and efficient metal cutting solutions on the market.Moreover, OEM Metal Cutting Machinery is known for its focus on quality and reliability. Each machine is manufactured using the highest quality components and undergoes rigorous testing to ensure that it meets the company's strict quality standards. This attention to detail and dedication to producing reliable machinery has earned OEM Metal Cutting Machinery the trust and loyalty of its customers.Furthermore, sustainability is a key priority for OEM Metal Cutting Machinery. The company is committed to minimizing its environmental impact by implementing eco-friendly practices in its manufacturing processes and reducing energy consumption. This dedication to sustainability not only benefits the environment but also demonstrates OEM Metal Cutting Machinery's commitment to responsible and ethical business practices.As the manufacturing industry continues to evolve, OEM Metal Cutting Machinery remains at the forefront of innovation, consistently pushing the boundaries of what is possible in metal cutting technology. The company's ongoing investment in research, development, and customer support ensures that it is well-positioned to meet the evolving needs of manufacturers around the world.In conclusion, OEM Metal Cutting Machinery has established itself as a leader in the metal cutting machinery industry, thanks to its unwavering commitment to innovation, quality, reliability, and customer satisfaction. With a diverse range of cutting machines, exceptional service and support, a focus on sustainability, and a dedication to continuous improvement, OEM Metal Cutting Machinery continues to set the standard for excellence in the manufacturing sector.

How Fiber Laser Cutting Systems Are Improving Manufacturing Processes

Fiber Laser Cutting Systems are revolutionizing the metal cutting industry with their precision, speed, and efficiency. One of the leading manufacturers of these cutting-edge machines is {Company X}, a global leader in advanced manufacturing technology. With a strong focus on innovation and customer satisfaction, {Company X} has been at the forefront of the industry for over two decades.The {Company X} Fiber Laser Cutting Systems are equipped with state-of-the-art technology that allows for fast and accurate cutting of a wide range of materials, including stainless steel, aluminum, copper, and titanium. These cutting systems are designed to meet the needs of various industries, from automotive and aerospace to medical and consumer electronics.One of the key features of {Company X} Fiber Laser Cutting Systems is their high precision, which is made possible by advanced motion control systems and intelligent software. This level of precision ensures that the finished parts meet the strictest quality standards, making them ideal for use in the most demanding applications.In addition to precision, {Company X} Fiber Laser Cutting Systems are known for their speed and efficiency. With high-powered laser sources and high-speed cutting heads, these machines can quickly and accurately cut complex shapes and intricate patterns, reducing production time and increasing overall productivity.Furthermore, {Company X} offers a range of Fiber Laser Cutting Systems to suit different production needs, from small, compact machines for smaller workshops to large, automated systems for high-volume production facilities. This flexibility makes {Company X} a preferred choice for businesses of all sizes, seeking to enhance their metal cutting capabilities.{Company X} not only provides cutting-edge machines but also offers comprehensive support and services to ensure that their customers get the most out of their investment. This includes training programs, maintenance services, and technical support, all aimed at keeping the Fiber Laser Cutting Systems running at peak performance.With a strong commitment to research and development, {Company X} is constantly pushing the boundaries of what is possible with Fiber Laser Cutting technology. Their team of engineers and technicians are always working on new innovations and improvements to further enhance the capabilities of their cutting systems, staying ahead of the curve and setting new industry standards.Through strategic partnerships and collaborations with other industry leaders, {Company X} continues to drive the advancement of Fiber Laser Cutting technology, ensuring that their customers have access to the latest and most advanced solutions for their metal cutting needs.In conclusion, {Company X} Fiber Laser Cutting Systems are setting new benchmarks in the metal cutting industry, providing unmatched precision, speed, and efficiency to a wide range of businesses. With a strong focus on innovation, customer satisfaction, and comprehensive support, {Company X} remains a trusted partner for those seeking to elevate their metal cutting capabilities. As the demand for high-quality, precision-cut parts continues to grow across various industries, {Company X} is well-positioned to meet and exceed these demands with their cutting-edge technology and unwavering commitment to excellence.

Enhance Your Marking Efficiency with Advanced Fiber Laser Marking Software

Fiber Laser Marking Software is Revolutionizing the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, precision and efficiency are key factors for success. With the introduction of Fiber Laser Marking Software by [Company Name], manufacturers now have access to a cutting-edge technology that is revolutionizing the way products are marked and identified. This innovative software, combined with the company's state-of-the-art fiber laser marking systems, is paving the way for a new era of quality and accuracy in manufacturing.[Company Name] has been a pioneering force in the laser marking industry for over 20 years. Their commitment to delivering advanced solutions for their customers has solidified their reputation as a leader in the field. The introduction of their Fiber Laser Marking Software is the latest example of their dedication to pushing the boundaries of what is possible in manufacturing technology.One of the key features of the Fiber Laser Marking Software is its user-friendly interface. The intuitive design makes it easy for operators to create and customize marking patterns with precision and efficiency. This level of control and customization is invaluable for manufacturers who require highly detailed and accurate markings on their products.The software also offers a wide range of marking options, including text, graphics, and 2D codes. This versatility allows manufacturers to meet the diverse marking requirements of their products, while maintaining the highest levels of quality and consistency.Another significant advantage of the Fiber Laser Marking Software is its compatibility with a variety of file formats, including CAD and graphics files. This seamless integration streamlines the production process, allowing for quick and easy conversion of design files into high-quality markings on the production line.In addition to these features, the software also offers advanced data management capabilities. Manufacturers can easily track and store marking data for quality control and traceability purposes. This level of data management is crucial for industries with stringent regulatory requirements, such as aerospace and medical device manufacturing.The introduction of Fiber Laser Marking Software is a game-changer for manufacturers seeking to optimize their production processes. The combination of this cutting-edge software with [Company Name]'s fiber laser marking systems is setting a new standard for marking precision and efficiency in the industry.[Company Name] is confident that their Fiber Laser Marking Software will empower manufacturers to achieve new levels of quality and consistency in their products. As the industry continues to evolve, [Company Name] remains dedicated to providing innovative solutions that meet the ever-changing needs of their customers.In conclusion, Fiber Laser Marking Software by [Company Name] is a groundbreaking technological advancement that is reshaping the manufacturing industry. Its user-friendly interface, versatile marking options, and advanced data management capabilities make it an invaluable tool for manufacturers seeking to achieve the highest standards of quality and efficiency in their production processes. With the introduction of this innovative software, [Company Name] continues to demonstrate their commitment to delivering cutting-edge solutions that push the boundaries of what is possible in manufacturing technology.

Advanced Compact Fiber Laser Technology Unveiled in Latest News

Compact Fiber Laser Revolutionizes Industrial Cutting and Marking ProcessesThe manufacturing industry has witnessed a significant revolution in recent years with the introduction of advanced technologies to enhance efficiency and quality. One of the key innovations driving this transformation is the compact fiber laser, which has become an indispensable tool for industrial cutting and marking processes. With its high precision, fast operation, and versatile capabilities, the compact fiber laser has set new standards for performance and reliability in the manufacturing sector.Despite its compact size, the compact fiber laser packs a powerful punch when it comes to cutting and marking a wide range of materials, including metals, plastics, ceramics, and more. Its advanced fiber laser technology delivers exceptional beam quality, allowing for precise and clean cuts with minimal heat-affected zones. This level of precision has revolutionized the manufacturing industry by enabling complex designs and intricate patterns to be achieved with utmost accuracy.In addition to its cutting capabilities, the compact fiber laser is also widely used for marking and engraving applications. Whether it is serial numbers, barcodes, logos, or decorative patterns, the compact fiber laser offers unmatched flexibility and speed for producing high-quality marks on various surfaces. This has made it an essential tool for product identification, branding, and customization across different manufacturing sectors.One of the key factors that set the compact fiber laser apart from traditional laser systems is its compact and ergonomic design. With its small footprint and user-friendly interface, it can be easily integrated into existing production lines or used as a standalone solution. This level of versatility and convenience has made the compact fiber laser a top choice for manufacturers seeking efficiency and flexibility in their operations.Furthermore, the compact fiber laser is known for its low power consumption and maintenance requirements, making it a cost-effective solution for long-term use. Its solid-state design and air-cooled operation eliminate the need for consumables or frequent maintenance, resulting in reduced downtime and operating costs for manufacturers. This has made it an attractive investment for businesses looking to improve their bottom line while enhancing their production capabilities.One company at the forefront of the compact fiber laser technology is {}. With a strong focus on innovation and customer satisfaction, {} has developed a range of compact fiber laser systems that are tailored to meet the diverse needs of the manufacturing industry. These systems are designed to deliver exceptional performance, reliability, and ease of use, ensuring that manufacturers can achieve their production goals with confidence.Moreover, {} offers comprehensive technical support and training to help customers maximize the potential of their compact fiber laser systems. From installation and setup to ongoing maintenance and troubleshooting, the company is dedicated to ensuring that its customers can fully leverage the capabilities of the compact fiber laser for their specific applications. This commitment to customer support has earned {} a reputation for excellence and a loyal customer base in the manufacturing sector.As the manufacturing industry continues to evolve, the compact fiber laser is expected to play an even greater role in shaping the future of industrial cutting and marking processes. With its unmatched precision, efficiency, and versatility, it has become a game-changer for businesses seeking to stay ahead in today's competitive market. As more manufacturers recognize the benefits of the compact fiber laser, its widespread adoption is sure to drive further advancements in manufacturing technology and bring new possibilities for innovation and growth.

Discover the Versatile Applications of Laser Cutting Machines

Title: Revolutionizing Industries: Expanding Possibilities with Laser Cutting MachinesIntroduction:In today's rapidly evolving world, laser cutting machines have emerged as revolutionary tools that have transformed a variety of industries. With the ability to cut through various materials with precision and efficiency, these advanced machines have become an indispensable asset for businesses, enabling increased productivity and versatility. This article will explore the myriad uses of laser cutting machines across different sectors, highlighting their impact on modern manufacturing and design processes.Automotive Industry:The automotive industry has greatly benefited from the advent of laser cutting machines. By utilizing these machines, car manufacturers can precisely cut intricate patterns and shapes into various materials, including steel, aluminum, and plastics, thereby facilitating the production of lightweight and fuel-efficient vehicles. Laser cutting technology also enables the creation of customized car parts with greater ease, allowing for improved product personalization and reduced manufacturing costs.Architecture and Construction:Laser cutting machines have revolutionized the architectural and construction industries by providing innovative solutions for creating intricate designs and precise cuts. These machines enable architects to push the boundaries of their creativity by effortlessly cutting various materials, such as glass, wood, and metal, to bring their envisioned designs to life. Additionally, laser cutting machines are utilized for precise metal fabrication, providing structural components that ensure the durability and strength of buildings.Fashion and Textiles:With laser cutting machines, the fashion and textiles industry has experienced a remarkable transformation in design and production. These machines enable designers to effortlessly cut intricate patterns into fabrics, leather, and other materials, enhancing the efficiency and accuracy of their creative process. Laser technology allows for precise and clean-cut edges, reducing the time-consuming manual labor required in traditional manufacturing methods. Moreover, laser cutting machines enhance the industry's sustainability by minimizing waste through optimized material usage.Electronics Manufacturing:Laser cutting machines play a pivotal role in the electronics manufacturing sector, facilitating the production of intricate circuit boards and precise electronic components. The machines' high precision and accuracy enable precise cuts, ensuring optimal functionality and reliability of electronic devices. Laser cutting also minimizes thermal damage during the cutting process, thereby optimizing the performance and longevity of electronic components.Medical and Healthcare:In the medical field, laser cutting machines are used in the fabrication of medical devices and implants. The precision offered by these machines allows for intricate and complex shapes to be cut into biocompatible materials, ensuring a perfect fit for patients. Additionally, laser technology aids in the creation of personalized medical devices tailored to individual patients, enhancing treatment effectiveness and patient satisfaction.Artistic Applications:Laser cutting machines have even found their way into the realm of art and creative expression. Artists and designers utilize these machines to produce intricate sculptures, decorative elements, and personalized artworks. The precision and flexibility afforded by laser cutting technology unleash boundless creative possibilities for artists, revolutionizing the art world and captivating audiences with stunning, intricate designs.Conclusion:The advent of laser cutting machines has ushered in a new era of possibilities across numerous industries. From automotive manufacturing to architecture, fashion, electronics, healthcare, and even the art sector, these versatile tools have become a driving force in achieving precision, efficiency, and high-quality production. With their ability to cut through various materials and create intricate designs, laser cutting machines have undoubtedly transformed the way businesses operate, offering endless opportunities for innovation and progress. As technology continues to advance, it is certain that laser cutting machines will continue to play an increasingly vital role in shaping the future of various industries around the globe.

Top Laser Manufacturing Company Reveals Latest Industry Trends and Innovations

Laser Manufacturing CompanyLaser Manufacturing Company is a leading provider of precision laser cutting and drilling services for a wide range of industries. With decades of experience and a commitment to quality and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-precision manufacturing solutions.The company's state-of-the-art facilities are equipped with the latest laser cutting and drilling technology, allowing them to provide precise and efficient machining services for a variety of materials, including metals, plastics, and ceramics. Their team of highly skilled engineers and technicians work closely with clients to understand their specific needs and requirements, providing custom solutions that meet the highest standards of accuracy and quality.In addition to their cutting-edge manufacturing capabilities, Laser Manufacturing Company also offers a range of value-added services, including CAD/CAM design and engineering support, material sourcing and procurement, and finishing and assembly services. This comprehensive approach allows them to provide end-to-end manufacturing solutions that streamline the production process and deliver exceptional results for their clients.With a focus on innovation and continuous improvement, Laser Manufacturing Company is constantly investing in new technology and refining their processes to stay ahead of the curve and ensure they can meet the evolving needs of their customers. They also pride themselves on their commitment to sustainability, implementing environmentally friendly practices and reducing waste wherever possible.In recent news, Laser Manufacturing Company has announced the launch of a new line of precision laser cutting machines that are set to revolutionize the industry. These advanced machines incorporate the latest advancements in laser technology, offering higher cutting speeds, improved accuracy, and greater versatility for a wide range of materials and thicknesses. This significant investment in new equipment highlights the company's dedication to providing the best possible manufacturing solutions for their clients."We are thrilled to introduce these state-of-the-art laser cutting machines to our production facilities," said the CEO of Laser Manufacturing Company. "We believe that this new equipment will not only improve our own capabilities but also provide significant benefits for our customers. The increased speed and accuracy will allow us to take on more complex projects and deliver even better results, further solidifying our position as a leader in precision manufacturing."The introduction of these new machines is just the latest example of Laser Manufacturing Company's commitment to pushing the boundaries of what is possible in precision laser cutting and drilling. By investing in cutting-edge technology and continually refining their processes, they have earned a reputation for excellence and reliability among their clients.As the manufacturing industry continues to evolve and become increasingly competitive, Laser Manufacturing Company is well-positioned to meet the growing demand for high-precision manufacturing solutions. With their focus on quality, innovation, and customer satisfaction, they are poised to remain a leader in the industry for years to come.

Revolutionizing Manufacturing: Discover the Power of Automated Production Equipment

Title: Revolutionizing Manufacturing: The Rise of Automated Production EquipmentIntroduction:In today's era of rapid technological advancements and increasing demand for efficiency, companies across the globe are steadily adopting automated production equipment. This revolutionary technology offers a wide range of benefits, from increased productivity and cost-effectiveness to enhanced safety and precision. One such industry leader in this area is **brand name**, a pioneer in delivering cutting-edge automated production equipment solutions. Let's delve into the world of automated production equipment and explore how it is reshaping the manufacturing landscape.1. Streamlined Processes and Efficiency Enhancement:Automated production equipment has revolutionized the traditional manufacturing processes by replacing manual operations with smart systems. These advanced machines are programmed to carry out repetitive tasks with higher efficiency and accuracy, greatly reducing the risk of human errors. By streamlining the production line, companies can optimize their operations, ensuring faster cycle times and improved product quality.By eliminating the reliance on manual labor for repetitive tasks, companies can redirect their workforce to more challenging and creative roles that require human skill and ingenuity. This leads to a more motivated and satisfied workforce while also alleviating the burden of monotonous tasks that offer little value to employees.2. Cost Reduction and Increased Productivity:Automated production equipment significantly reduces the overall manufacturing costs, especially when compared to traditional labor-intensive practices. Once implemented, the initial investment in automated systems is often recouped through increased productivity over time. Additionally, these machines operate 24/7, ensuring round-the-clock production without incurring additional labor costs.By adopting automated production equipment, companies can minimize waste, optimize raw material usage, and enhance inventory management. With improved precision and accuracy, production defects and reworks are significantly reduced, leading to cost savings and a higher rate of customer satisfaction.3. Enhanced Safety and Compliance:Manually operated machinery can pose a significant safety risk to workers, especially in hazardous manufacturing environments. The utilization of automated production equipment helps create safer working conditions by minimizing human exposure to potential accidents. These machines are equipped with advanced safety features such as emergency-stop systems, sensors, and self-diagnostic capabilities, ensuring a secure working environment.Furthermore, automated systems are also designed to comply with stringent industry regulations and standards. By automating processes, companies can reduce the risk of non-compliance, penalties, and legal disputes, thus ensuring a smoother manufacturing process while adhering to established guidelines.4. Precision and Quality Control:Automated production equipment is known for its high precision and consistency, resulting in superior product quality. Advanced sensor technologies and real-time monitoring allow for in-process measurements and adjustments, ensuring the production of precise, error-free components.Moreover, these machines provide real-time data analytics, enabling manufacturers to continuously monitor and optimize their production processes. By identifying performance bottlenecks and areas for improvement, companies can enhance production quality, minimize defects, and offer products that meet or exceed customer expectations.Conclusion:As manufacturing industries strive to remain competitive and efficient, the adoption of automated production equipment has emerged as a game-changer. Through streamlined processes, cost reduction, increased productivity, and enhanced safety, companies can unlock new levels of efficiency and profitability. With the industry pioneers, including **brand name**, setting new benchmarks, it is clear that this technology is here to stay. The future of manufacturing lies in the hands of automated production equipment, driving innovation and transforming the way businesses operate.

Ultimate Guide to Choosing the Best Welding Machine for Your Needs

Introducing The Ultimate Welding Machine – Revolutionizing the Welding IndustryWith the increasing demand for precision and efficiency in welding, the welding machine has evolved immensely over the years. Today, we introduce the ultimate welding machine that revolutionizes the welding industry – a welding machine that has set new industry standards, while also setting a benchmark for the future of welding.The welding machine (brand name removed for privacy reasons) is the brainchild of a German engineering company that specializes in designing and manufacturing technologically advanced welding solutions for diverse industries. With their expertise and passion for innovation, they have created a welding machine that caters to the ever-growing needs of the welding industry.The welding machine combines the latest features and technologies in welding, making it the most advanced machine in the market. It is equipped with state-of-the-art welding processes such as MIG/MAG, TIG, and MMA welding, making it versatile and flexible in its welding applications. The machine has a current range suited for welding aluminum, copper, steel, and other materials, thus making it an all-inclusive machine for welding professionals.One of the most notable features of the welding machine is its intuitive control panel. The company has ensured that the control panel is user-friendly, making it easy for welders to navigate and select the appropriate settings for their welding applications. The control panel also has a digital display that shows essential welding parameters such as voltage, current, and wire feed speed, making it easier for welders to monitor the welding process and achieve the desired welding outcome.The welding machine (brand name removed for privacy reasons) is also designed to be highly efficient, ensuring maximum productivity and output for welding projects. It has an innovative wire feeding system that ensures continuous and precise wire feeding, reducing the risk of weld defects and enhancing accuracy in the welding process. The machine's advanced cooling system also ensures stable and consistent welding performance, even in high-temperature environments.To ensure safety in the welding process, the welding machine is equipped with various safety features. It has an overheat protection system that prevents the machine from overheating, thus prolonging its lifespan. The machine also has a robust casing that protects it from physical damage, ensuring that it remains durable and robust under different working environments.The welding machine is also environmentally friendly, with a low power consumption rate and minimal carbon footprint. The company has ensured that the welding machine is compliant with various welding environment standards, making it an eco-friendly and sustainable choice among welding professionals.In conclusion, the welding machine (brand name removed for privacy reasons) is a robust and reliable welding machine that meets the demands of the welding industry. It brings together innovative technologies, user-friendliness, efficiency, safety, and environmental friendliness in a remarkable way. The machine is a perfect choice for welding professionals who demand precision, efficiency, variety, and safety in their welding process. The company has set a new standard for welding machines, and it is safe to say that this is the ultimate welding machine that is set to revolutionize the welding industry.

How Laser Cleaning Machines are Revolutionizing Industrial Cleaning Technology

Introducing Fiber Laser Cleaning Machine: Revolutionizing Industrial Cleaning Processes[Company Introduction]In today's rapidly evolving industrial landscape, the need for efficient and environmentally friendly cleaning processes has become more vital than ever. Recognizing this demand, {Company Name}, a global leader in advanced manufacturing solutions, proudly presents its latest innovation – the Fiber Laser Cleaning Machine. This cutting-edge technology aims to revolutionize industrial cleaning by providing a highly effective, precise, and eco-friendly solution for various industries.[Overview of Fiber Laser Cleaning Machine]The Fiber Laser Cleaning Machine is a state-of-the-art equipment designed to remove contaminants, rust, and unwanted coatings from the surfaces of various materials, including metal, plastic, and stone. Utilizing high-intensity laser beams, this innovative cleaning system offers a non-contact and non-abrasive approach to industrial cleaning, ensuring the preservation of delicate surfaces and eliminating the need for costly and potentially damaging chemical agents.[Features and Benefits]1. Superior Cleaning Performance: The Fiber Laser Cleaning Machine employs a high-power laser beam, which generates a powerful and focused energy that effectively disintegrates and vaporizes contaminants. This process ensures that even the most stubborn residues, such as grease, rust, or paint, are thoroughly removed, leaving behind a pristine surface.2. Precision and Versatility: With advanced scanning technology, users have the flexibility to tailor the cleaning patterns and intensity according to their specific requirements. Whether it's cleaning intricate machinery parts, large-scale industrial equipment, or historical artifacts, the Fiber Laser Cleaning Machine offers unparalleled precision and adaptability.3. Environmentally Friendly Solution: In a world increasingly focused on sustainability, the Fiber Laser Cleaning Machine sets new standards for eco-friendly cleaning solutions. By eliminating the need for harsh chemicals or solvents, this innovative system significantly reduces waste generation and eliminates harmful emissions, ensuring a safer working environment for employees and reducing environmental impact.4. Cost-effective and Time-efficient: The Fiber Laser Cleaning Machine is a cost-effective alternative to traditional cleaning methods. With its high cleaning speed and efficiency, it minimizes downtime, maximizing productivity, and reducing labor costs. Additionally, its non-abrasive nature, which eliminates the risk of surface damage, reduces the need for costly repairs and replacements.5. Enhanced Safety: The Fiber Laser Cleaning Machine prioritizes the safety of its users. Equipped with protective shields and safety features, it minimizes the risk of accidents and injuries, ensuring operators can work confidently and securely. Furthermore, the laser system's non-toxic and non-contact cleaning mechanism provides a safer working environment for employees.[Applications]The Fiber Laser Cleaning Machine finds extensive applications across various industries, including:1. Automotive: Removing rust, paint, and coatings from car bodies, parts, and engine components.2. Aerospace: Cleaning critical components, such as turbine blades, without damaging their delicate surfaces.3. Manufacturing: Eliminating contaminants from tools, molds, and machinery parts, ensuring optimal performance and prolonging their lifespan.4. Restoration: Safely restoring historical artifacts, sculptures, and antiques without causing any irreversible damage.5. Electronics: Cleaning delicate electronic circuits, PCBs, and components without the need for chemicals or solvents.[Future Prospects]As industries continue to seek efficient and sustainable cleaning solutions, the Fiber Laser Cleaning Machine presents a promising future. Its advanced capabilities not only enhance cleaning processes but also contribute to increased productivity, reduced costs, and a safer working environment for employees. With continuous research and development, {Company Name} is committed to pushing the boundaries of innovation, fostering industrial growth, and addressing the evolving needs of its clients.In conclusion, the introduction of the Fiber Laser Cleaning Machine marks a significant milestone in the field of industrial cleaning. Its ability to combine cutting-edge technology, environmental consciousness, precision, and cost-effectiveness sets it apart from traditional cleaning methods. With {Company Name}'s dedication to advancing manufacturing solutions, the Fiber Laser Cleaning Machine is poised to reshape industrial cleaning practices, optimize efficiency, and pave the way for a cleaner and more sustainable future.

Top-notch Laser Cutting Services for All Your Cutting Needs

Title: Leading Laser Cutting Service Provider Revolutionizes Precision FabricationIntroduction:In today's rapidly evolving manufacturing landscape, precision and efficiency are the driving forces behind successful businesses. One company at the forefront of this revolution is Best Laser Cutting Service (BLCS), an industry leader in delivering exceptional laser-cutting solutions. BLCS stands out from the competition with its commitment to state-of-the-art technology, unparalleled expertise, and unyielding dedication to customer satisfaction. With a diverse range of applications and a reputation for excellence, BLCS is transforming the field of precision fabrication.Overview of Best Laser Cutting Service:BLCS, a prominent player in the laser-cutting industry, has been instrumental in delivering cutting-edge solutions for a variety of sectors. With years of experience, the company's team of experts harnesses the power of advanced laser technology to meet the unique requirements of clients. From intricate metal designs to complex fabrication tasks, BLCS offers a comprehensive range of services that consistently meet the highest industry standards.Advanced Laser Technology:BLCS prides itself on staying ahead of the curve when it comes to technology. The company utilizes cutting-edge laser cutting machines, equipped with high-strength lasers capable of delivering precise and intricate cuts. By incorporating the latest in laser technology, BLCS ensures superior accuracy, faster turnaround times, and increased productivity for clients across industries.Diverse Applications:With a deep understanding of various industries, BLCS caters to a wide spectrum of clients. The company offers laser-cutting services for metals such as steel, aluminum, copper, and more. BLCS's versatility enables it to serve diverse sectors including aerospace, automotive, electronics, construction, and even the creative arts. This extensive range of applications showcases the flexibility and adaptability of BLCS, reaffirming its position as a leading provider of innovative laser cutting solutions.Quality Assurance and Expertise:BLCS places a strong emphasis on quality assurance, ensuring that every project meets or exceeds customer expectations. The team of highly skilled technicians and engineers at BLCS possesses a wealth of experience and knowledge in laser cutting. From consulting on designs to using the most suitable techniques, BLCS offers expert guidance throughout the fabrication process. This collaborative approach ensures that clients receive superior results while optimizing cost-effectiveness.Commitment to Customer Satisfaction:At the core of BLCS's success lies its unwavering commitment to customer satisfaction. The company understands that every client has unique requirements, and it goes the extra mile to create tailored solutions. By providing rapid prototyping, efficient production processes, and exceptional customer service, BLCS ensures that clients' projects are completed accurately and on time.Contributing Towards Sustainability:BLCS also recognizes its responsibility towards environmental sustainability. The company actively adopts eco-friendly practices by minimizing waste materials and optimizing energy efficiency. By staying at the forefront of sustainable practices, BLCS not only meets industry expectations but also contributes to a greener future.Conclusion:Best Laser Cutting Service (BLCS) has established itself as a pioneering force in the laser-cutting industry. With its cutting-edge technology, diverse applications, unwavering dedication to excellence, and commitment to sustainability, BLCS continues to redefine precision fabrication. Through superior quality, customer-centric approach, and continuous innovation, BLCS ensures that businesses across industries can achieve their desired outcomes with unmatched precision and efficiency.