New Co2 Tube Technology Reduces Carbon Emissions

By:Admin

Co2 Tube, developed by a leading environmental technology company, is a cutting-edge solution that effectively captures and stores carbon dioxide emissions. The product's advanced technology allows for the efficient and sustainable reduction of Co2 emissions, thereby contributing to a significant improvement in air quality and a reduction in the impact of climate change.

The company, with a strong commitment to environmental sustainability, has been at the forefront of developing groundbreaking solutions to address the pressing issue of carbon emissions. With a team of dedicated scientists and engineers, the company has invested significant resources in research and development to create Co2 Tube, a product that has the potential to transform the way industries approach carbon reduction.

One of the key features of Co2 Tube is its versatility and adaptability to a wide range of industries. From power plants to manufacturing facilities, Co2 Tube can be seamlessly integrated into existing infrastructure to capture and store carbon emissions. This flexibility has made Co2 Tube a preferred choice for companies looking to implement sustainable practices and reduce their carbon footprint.

Moreover, the company has ensured that Co2 Tube complies with the highest industry standards for safety and efficiency. Through rigorous testing and quality control measures, Co2 Tube has been proven to consistently deliver exceptional performance, making it a reliable and trustworthy solution for carbon capture and storage.

In addition to its technological advancements, Co2 Tube is also designed to be cost-effective, offering companies an economically viable option for carbon reduction. By implementing Co2 Tube, companies can not only contribute to environmental sustainability but also benefit from potential cost savings and a positive impact on their bottom line.

The company's commitment to sustainability extends beyond the development of Co2 Tube. It has also been actively involved in promoting awareness and education about the importance of carbon reduction and environmental conservation. Through various initiatives and partnerships, the company has been advocating for the adoption of sustainable practices and the implementation of innovative solutions like Co2 Tube.

The growing recognition and adoption of Co2 Tube in various industries are a testament to its effectiveness and potential to make a meaningful impact on the global effort to combat climate change. As more and more companies prioritize environmental sustainability, Co2 Tube is poised to play a significant role in helping them achieve their carbon reduction goals.

Looking ahead, the company remains dedicated to advancing its environmental technology solutions, with a focus on developing new and improved products that offer even greater efficiency and effectiveness in carbon capture and storage. With ongoing research and innovation, the company is confident that it will continue to lead the way in providing sustainable solutions for a greener and healthier planet.

In conclusion, Co2 Tube represents a milestone in environmental technology, offering a practical and effective solution for carbon capture and storage. With the company's unwavering commitment to sustainability and innovation, Co2 Tube is set to make a lasting impact on the global effort to reduce carbon emissions and combat climate change.

Company News & Blog

Ultimate Guide to Co2 Laser Cutter Prices: What You Need to Know

The growing demand for precision cutting and engraving solutions has led to an increasing interest in CO2 laser cutters. These advanced machines are capable of delivering high-quality results across a wide range of materials, making them a valuable addition to any manufacturing or production facility.One company at the forefront of this trend is {company name}. With a strong focus on innovation and quality, {company name} has established itself as a leading provider of CO2 laser cutters. The company's commitment to delivering cutting-edge technology and exceptional service has earned it a reputation as a trusted partner for businesses seeking reliable and efficient cutting solutions.In line with its dedication to meeting the evolving needs of its customers, {company name} has announced a competitive pricing strategy for its CO2 laser cutters. The company's decision to offer a compelling price point for its advanced machines is aimed at making cutting-edge technology more accessible to a wider audience. This move is expected to appeal to a diverse range of businesses, from small-scale operations to large manufacturing facilities, seeking high-performance cutting solutions that deliver exceptional results.{Company name}'s CO2 laser cutters are designed to meet the demands of modern manufacturing and production environments. With their ability to cut and engrave a variety of materials, including wood, acrylic, leather, and more, these advanced machines offer versatility and precision. The company's commitment to delivering high-quality solutions is reflected in the performance and reliability of its CO2 laser cutters, making them an ideal choice for businesses looking to enhance their cutting and engraving capabilities.The competitive pricing of {company name}'s CO2 laser cutters is further complemented by the company's dedication to customer satisfaction. {Company name} has a strong track record of providing exceptional service and support to its customers, ensuring that they receive the guidance and assistance they need to make the most of their investment. This commitment to customer care sets {company name} apart as a trusted partner for businesses seeking reliable and efficient cutting solutions.With its combination of cutting-edge technology, exceptional performance, and competitive pricing, {company name} is well-positioned to meet the growing demand for CO2 laser cutters. By offering a compelling price point for its advanced machines, the company is making it easier for businesses to access the cutting-edge technology they need to enhance their production capabilities. With a strong focus on innovation and customer satisfaction, {company name} is poised to remain a leader in the field of CO2 laser cutting solutions.In conclusion, the announcement of competitive pricing for {company name}'s CO2 laser cutters reflects the company's commitment to meeting the evolving needs of its customers. With their advanced technology, exceptional performance, and dedication to customer satisfaction, {company name} is well-positioned to serve as a trusted partner for businesses seeking reliable and efficient cutting solutions. As the demand for precision cutting and engraving solutions continues to grow, {company name} is poised to play a key role in providing the high-quality technology that businesses need to thrive in today's competitive market.

High-Powered Fiber Laser Cutting for Stainless Steel: Key Benefits

With the continuous development of technology, fiber laser cutting technology has been widely used in various industrial fields, especially in the field of stainless steel processing. The fiber laser cutting machine of {company} is a high-tech product equipped with cutting-edge technology, which has greatly improved the efficiency and precision of stainless steel processing.{Company} is a leading manufacturer of fiber laser cutting machines, specializing in the research, development, and production of high-quality laser cutting equipment. The company has a strong R&D team and production capacity, with advanced laser cutting technology and reliable product quality. Its fiber laser cutting machines have been widely recognized and praised in the industry, and have been successfully applied in various fields such as metal processing, automobile manufacturing, aerospace, and precision machinery manufacturing.The fiber laser cutting machine of {company} is specifically designed for stainless steel processing. With the use of advanced fiber laser technology, it has the advantages of high cutting precision, fast cutting speed, and smooth cutting edges. The machine can effectively process different thicknesses of stainless steel materials, and the cutting quality is highly consistent and stable. It is an ideal choice for stainless steel processing, providing efficient and reliable cutting solutions for industrial production.One of the key features of {company}'s fiber laser cutting machine is its high efficiency. The machine is equipped with a high-power fiber laser generator, which can output a high-energy laser beam to quickly and accurately cut the stainless steel material. The cutting speed is significantly improved compared to traditional cutting methods, which greatly reduces the processing time and improves production efficiency. In addition, the machine is also equipped with advanced laser cutting control system and intelligent cutting software, which can automatically optimize the cutting path and parameters, further improving the cutting efficiency and reducing material waste.Moreover, the fiber laser cutting machine of {company} has a high degree of flexibility and versatility. It is capable of cutting complex shapes and patterns on stainless steel materials, meeting the diverse needs of industrial production. Whether it is simple straight-line cutting, or intricate contour cutting, the machine can achieve precise and high-quality cutting results. In addition, the machine also supports automated processing, and can be integrated into the production line for continuous and efficient operation, realizing unmanned and intelligent production.In terms of environmental protection and energy saving, {company}'s fiber laser cutting machine is also outstanding. It uses a fiber laser as the cutting source, which has the advantages of high electro-optical conversion efficiency and low power consumption. Compared to traditional cutting methods, it has a significant reduction in energy consumption and carbon emissions, promoting green and sustainable manufacturing. The machine is also equipped with a professional exhaust system and dust collection device, effectively controlling the processing fumes and dust from the cutting process, creating a clean and healthy working environment.In conclusion, the fiber laser cutting machine of {company} is a cutting-edge and reliable solution for stainless steel processing, providing high-efficiency, high-precision, and environmentally friendly cutting technology. With its advanced technology and superior performance, it has been widely used in various industries, playing a crucial role in promoting the development of stainless steel processing and industrial manufacturing. In the future, {company} will continue to innovate and optimize its fiber laser cutting technology, providing more advanced and efficient cutting solutions for the industry.

New fiber laser cutting machines offer unparalleled precision and efficiency, with all-in-one cells to maximize savings.

Fiber Laser Cutting: The Future of Precision ManufacturingIn today's fast-paced manufacturing world, precision and speed are critical factors that determine the success of a business. To stay ahead of the competition, manufacturers are always looking for new and innovative technology to help them improve their efficiency and productivity.One such technology that is rapidly gaining popularity is fiber laser cutting. Unlike traditional cutting methods, fiber laser cutting uses a high-powered laser beam to cut through a wide range of materials with unmatched precision, speed, and efficiency.Here are some of the key benefits of fiber laser cutting:Unmatched Accuracy: One of the most significant advantages of fiber laser cutting is its unmatched accuracy. The laser beam is incredibly precise and can cut through materials with a precision of up to 0.001mm. This level of accuracy is impossible to achieve with traditional cutting methods.High Speed: In addition to accuracy, fiber laser cutting is also incredibly fast. The laser beam can cut through materials at a rate of up to 40 meters per minute, which is much faster than traditional cutting methods like sawing or milling.Versatile: Fiber laser cutting can cut through a wide range of materials, including metal sheets, tubes, pipes, and profiles. This versatility makes it an ideal solution for a wide range of industries, including automotive, aerospace, and construction.Minimal Waste: Traditional cutting methods like sawing or milling produce a significant amount of waste material. In contrast, fiber laser cutting produces minimal waste, making it a more environmentally friendly option.Cost-Effective: While fiber laser cutting machines are typically more expensive to purchase than traditional cutting machines, they offer significant cost savings over the long term. The high precision and speed of fiber laser cutting mean that less waste is produced, resulting in lower material costs.If you are interested in investing in a fiber laser cutting machine, you may be wondering about the cost of the cutting head.The cost of a fiber laser cutting head can vary depending on several factors, including the power of the laser, the size of the cutting head, and the specific features of the head.On average, a fiber laser cutting head can range in price from a few thousand dollars to tens of thousands of dollars. However, it's important to note that the cost of the cutting head is just one factor to consider when purchasing a fiber laser cutting machine.Ultimately, the cost-effectiveness of a fiber laser cutting machine will depend on several factors, including your specific business needs, the materials you plan to cut, and the volume of production required.In conclusion, fiber laser cutting is an innovative technology that offers unmatched precision, speed, and efficiency. If you're looking to improve your manufacturing processes, investing in a fiber laser cutting machine could be the solution you need. While the cost of the cutting head is an important consideration, it's just one factor to consider when evaluating the overall cost-effectiveness of the technology.

Top Laser Machines in China for Superior Performance and Precision

China Lin Laser Machine Revolutionizes Industrial Manufacturing with Cutting-Edge Technology[City, Date] - In the realm of industrial manufacturing, innovation is key to staying ahead in an ever-evolving market. China Lin Laser Machine, renowned for its cutting-edge technology, has emerged as a game-changer. With its pioneering machinery and commitment to customer satisfaction, the company has revolutionized the manufacturing industry.Since its inception, China Lin Laser Machine has been at the forefront of technological advancements within the industrial manufacturing sector. The company's state-of-the-art laser machines have set new standards for precision, efficiency, and reliability. By combining innovative features with exceptional build quality, China Lin Laser Machine has become an industry leader trusted by businesses worldwide.One of the key factors contributing to the company's success is its dedication to research and development. China Lin Laser Machine invests significantly in finding breakthrough solutions that address the evolving needs of manufacturers. By employing a team of highly skilled engineers and collaborating with industrial experts, the company consistently develops cutting-edge technology that caters to the unique requirements of its customers.China Lin Laser Machine's product portfolio boasts an impressive range of advanced laser machines, each designed to cater to different manufacturing needs. The company offers laser cutting machines, laser welding machines, and laser engraving machines.Laser cutting machines from China Lin Laser Machine are renowned for their unparalleled precision and speed. Equipped with the latest laser technology, these machines are capable of cutting through various materials with exceptional accuracy, enabling manufacturers to achieve complex designs swiftly and effortlessly. The versatility offered by these machines allows businesses to explore new possibilities and expand their product offerings.The laser welding machines offered by China Lin Laser Machine are designed to deliver superior quality welds while significantly reducing production time. These machines make use of advanced laser systems that offer precise control over welding parameters, resulting in stronger and more durable welds. With the ability to seamlessly join different materials, China Lin Laser Machine's laser welding machines are ideal for a wide range of industrial applications.China Lin Laser Machine's laser engraving machines provide manufacturers with the ability to create highly detailed and intricate designs on various materials. These machines utilize advanced laser technology to etch precise patterns, logos, or text onto surfaces with impeccable accuracy. From personalized promotional items to intricate art pieces, the possibilities are endless with China Lin Laser Machine's laser engraving machines.The company's commitment to embedding cutting-edge technology into every machine is paired with a focus on customer satisfaction. China Lin Laser Machine believes in building long-term relationships with its clients, providing comprehensive support and assistance throughout the entire lifecycle of its machinery. The company's dedicated customer service team ensures that customers receive the technical expertise and guidance necessary to optimize the performance of China Lin Laser Machine's products.With a strong presence in both domestic and international markets, China Lin Laser Machine is continuously expanding its reach. By participating in prominent industry exhibitions and fostering global partnerships, the company aims to further establish itself as a global leader in industrial manufacturing technology.In conclusion, China Lin Laser Machine has revolutionized the industrial manufacturing sector through its cutting-edge laser machines. The company's commitment to innovation and customer satisfaction has set new standards for precision, efficiency, and reliability within the industry. With its diverse range of advanced laser machines and comprehensive customer support, China Lin Laser Machine is poised to shape the future of manufacturing.

Video highlights top features of CNC fiber laser cutting machines for metal materials

, CNC Fiber Laser, High Precision Cutting, Metal Cutting.In today's world, the demand for precision cutting has increased manifold. Be it in the manufacturing industry or the automobile sector, precision cutting is required in all areas of modern production. And with the advancement in technology, we have seen a significant change in the machines that are used for cutting metals.One of the most widely used machines for high precision cutting is the CNC fiber laser cutting machine. A CNC fiber laser cutting machine is a technological marvel that uses an advanced fiber laser generator and ball screw moving system to cut different kinds of metal with high precision and speed.CNC fiber laser cutting machines offer a competitive edge to businesses by increasing their productivity and efficiency. They are also easy to operate, and their maintenance or adjustment does not require much time or effort. In this blog post, we will delve into the features and benefits of CNC fiber laser cutting machines.High Precision Cutting with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their precision cutting capabilities. They use advanced fiber laser generator technology to produce a high-intensity laser beam, which is then used to cut the metal with great precision. CNC fiber laser cutting machines can cut through different thicknesses of metals, including stainless steel, carbon steel, and aluminum, with great accuracy.The precision cutting feature of CNC fiber laser cutting machines makes them a perfect tool for creating intricate shapes and patterns in metals. They are ideal for making complex cuts needed in industries like aerospace, manufacturing, and automotive.Increased Efficiency with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their high-speed operation. They can perform cuts at a much faster pace than other cutting machines in the market. The ball screw moving system used in CNC fiber laser cutting machines ensures that the machine moves smoothly and quickly, resulting in faster processing times.The high-speed operation of CNC fiber laser cutting machines makes them an ideal choice for businesses that need to cut a large number of metal pieces in a short amount of time. This efficiency helps businesses reduce their production times and increase their output.Low Maintenance and Easy to OperateAnother significant advantage of CNC fiber laser cutting machines is their low maintenance requirements. Since the laser is transmitted by fiber, there is no need for frequent maintenance or adjustments to the laser optical path. This reduces operational costs while ensuring consistent, high-quality results.CNC fiber laser cutting machines are also easy to operate. They come with user-friendly software that allows operators to design and execute precise cuts without any hassle. The software allows for customization of shapes and patterns, enabling greater design flexibility for businesses.ConclusionCNC fiber laser cutting machines are changing the way businesses cut metals today. Their high precision, speed, and efficiency have made them a preferred choice for industries that require precise cutting and fast processing times. Their low maintenance and ease of use have made them a cost-effective tool for businesses of all sizes.If you are looking for a machine that can cut metal with precision and speed while reducing your operational costs, CNC fiber laser cutting machines are the answer. Invest in a CNC fiber laser cutting machine today and experience the benefits firsthand!

High-Precision Laser Cutting Machine for Various Materials

Shandong Man Machinery Equipment Co., Ltd., a leading provider of innovative manufacturing solutions, has announced the launch of its newest product line, the Laser Cutting Machine. This machine is designed to provide a highly efficient and reliable solution for cutting a variety of materials, including acrylic, MDF, wood, and more.The Laser Cutting Machine is equipped with advanced laser technology that allows for precision cutting of even the most complex designs. This machine is ideal for use in a wide range of industries, including advertising, signage, furniture manufacturing, and more.One of the key features of the Laser Cutting Machine is its ability to cut a wide range of materials, including acrylic, MDF, wood, and more. This makes it a highly versatile solution for businesses that need to cut different materials for different applications.In addition, the Laser Cutting Machine is designed with safety in mind, featuring a range of safety features that protect operators and reduce the risk of accidents. These safety features include an interlock system that prevents the machine from operating if the safety cover is open, as well as a laser protection system that shields operators from the laser beam.Another key feature of the Laser Cutting Machine is its ease of use. This machine is designed to be user-friendly, with a simple and intuitive interface that allows operators to quickly and easily program the machine for their specific cutting needs.The Laser Cutting Machine is also designed to be highly efficient, with a fast cutting speed that helps businesses to increase production and reduce waste. This machine is equipped with high-quality laser components that ensure reliable and consistent performance, even with heavy use.Overall, the Laser Cutting Machine represents a highly innovative and efficient solution for businesses that need to cut a wide range of materials for different applications. With its advanced laser technology, safety features, ease of use, and efficiency, this machine can help businesses to increase their productivity and profitability, while also providing a high-quality cutting solution for their customers.Shandong Man Machinery Equipment Co., Ltd. is proud to offer the Laser Cutting Machine as part of its commitment to providing innovative and effective manufacturing solutions to businesses around the world.

Advanced Fiber Laser Technology in the News

[Company Name] Launches Advanced Machine Fiber Laser for Precision Metal Cutting[City], [Date] - [Company Name], a leading manufacturer of industrial cutting equipment, has recently announced the launch of its latest innovation, the [Model Name] Fiber Laser. This state-of-the-art machine is designed to provide high-precision metal cutting capabilities for a wide range of industrial applications, making it an ideal solution for manufacturers looking to optimize their production processes.The [Model Name] Fiber Laser incorporates advanced fiber laser technology to deliver superior cutting performance and exceptional accuracy. Equipped with a high-powered laser source, this cutting-edge machine is capable of cutting various metals, including stainless steel, aluminum, and copper, with incredible speed and precision. Its advanced laser technology allows for smooth and clean cuts, minimizing the need for secondary processing and reducing material waste.In addition to its cutting-edge laser technology, the [Model Name] Fiber Laser also features a user-friendly interface and intuitive controls, making it easy to operate and maintain. With its high-speed cutting capabilities and advanced motion control system, this machine is able to significantly enhance productivity and efficiency in metal fabrication processes, helping manufacturers meet their production targets with ease.Furthermore, the [Model Name] Fiber Laser is designed with versatility in mind, enabling it to accommodate a wide range of cutting requirements. Whether it's intricate designs, complex shapes, or thick plates, this machine is capable of handling a myriad of cutting tasks with utmost precision and consistency. Its advanced cutting head and automatic focus adjustment system ensure optimal cutting performance across a variety of material thicknesses, making it a versatile solution for diverse industrial applications."We are thrilled to introduce the [Model Name] Fiber Laser to the market, as it represents a significant leap forward in metal cutting technology," said [Spokesperson Name], [Job Title] at [Company Name]. "This advanced machine is a testament to our commitment to delivering cutting-edge solutions that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations."In addition to its cutting-edge technology, the [Model Name] Fiber Laser is also backed by [Company Name]'s renowned customer support and service. With a global network of service technicians and technical support teams, [Company Name] is dedicated to providing assistance and expertise to ensure that customers get the most out of their investment in the [Model Name] Fiber Laser. Whether it's installation, training, or maintenance, customers can rely on [Company Name] to provide comprehensive support throughout the lifecycle of their machine.The launch of the [Model Name] Fiber Laser underscores [Company Name]'s ongoing commitment to innovation and excellence in the realm of industrial cutting equipment. With its advanced capabilities, user-friendly design, and versatile performance, this cutting-edge machine is poised to redefine metal cutting processes and empower manufacturers to elevate their production capabilities to new heights.For more information about the [Model Name] Fiber Laser and [Company Name]'s complete range of cutting solutions, visit [Company Website] or contact [Company Name] directly.About [Company Name]:[Company Name] is a leading manufacturer of industrial cutting equipment, specializing in advanced solutions for metal fabrication and manufacturing. With a passion for innovation and a commitment to excellence, [Company Name] continually strives to develop cutting-edge technologies that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations. With a global presence and a dedication to customer satisfaction, [Company Name] is recognized as a trusted partner for companies seeking high-quality cutting solutions that deliver exceptional performance and value.

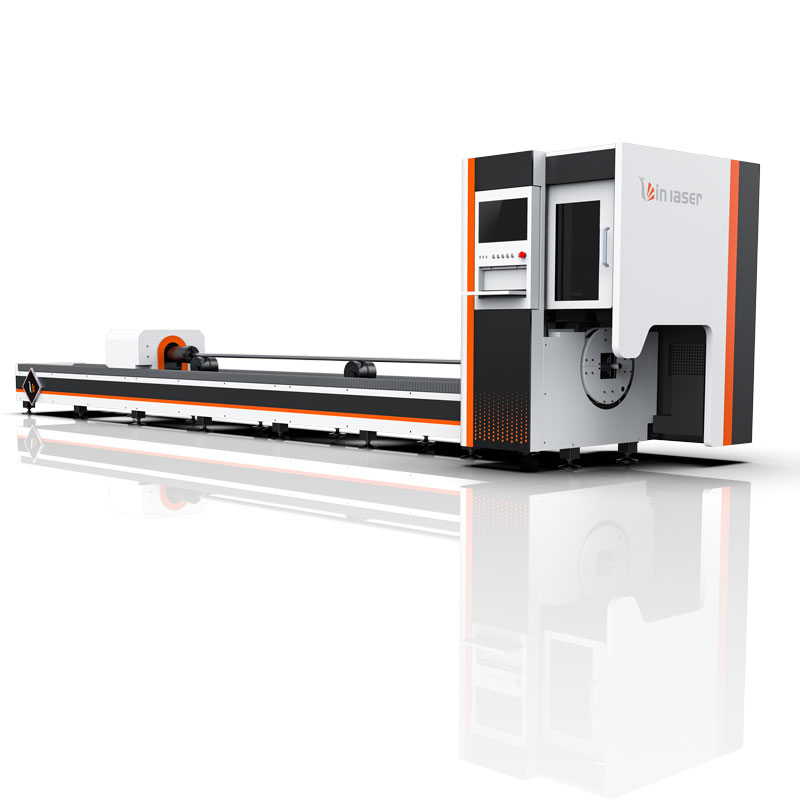

The Complete Guide to Fiber Laser Pipe Cutting Machines in 2021 for Metal Fabrication

: The Ultimate Solution for Precision Pipe Cutting.The demand for metal pipes is increasing day by day, with more industries relying on them for various purposes. From plumbing to construction, pipes play a vital role in the smooth functioning of operations. However, cutting these pipes to precise lengths can be a challenge. Traditional cutting methods can be time-consuming and may compromise the accuracy of the cuts. To overcome these drawbacks, metal laser pipe cutting machines have emerged as the ultimate solution.Fiber Laser Pipe Cutter – The Ultimate SolutionThe invention of fiber laser technology gave rise to highly efficient and precise metal cutting machines. Fiber laser pipe cutters are specifically designed for cutting metal pipes with high precision and accuracy. These machines use a beam of light to cut through metal pipes, leaving smooth and precise edges without any deformation of the material. The laser beam can cut through different types of metals, including stainless steel, mild steel, and aluminum.Advantages of Fiber Laser Pipe Cutting Machine1. High PrecisionFiber laser pipe cutters offer high precision cuts with a tolerance of up to ±0.1mm. This level of accuracy ensures that pipes fit perfectly without any gaps or overlaps, minimizing wastage of materials.2. High Production SpeedFiber laser pipe cutters can cut through pipes at high speeds, making them ideal for large scale production. The machines can cut different types of pipes and thicknesses, which increases the flexibility of the operating process.3. Reduced Labor CostsFiber laser pipe cutters require minimal human intervention, reducing labor costs. Operators do not require specific technical expertise to operate the machine, as the process is fully automated.4. Reduced Material WastageFiber laser pipe cutters have a narrow laser beam, which results in minimal wastage of materials. This, coupled with high precision cuts, results in increased material savings.5. Minimal MaintenanceFiber laser pipe cutters are easier to maintain compared to traditional cutting machines. The machines require minimal manual intervention, reducing the need for frequent maintenance.Applications of Fiber Laser Pipe CuttersFiber laser pipe cutters are commonly used in various fields, including:1. ConstructionFiber laser pipe cutters cut metal pipes to precise lengths required for building construction. The accurate cuts ensure that the pipes fit perfectly, minimizing the chances of leaks.2. Automotive IndustryThis industry uses fiber laser pipe cutters to produce exhaust systems with complex shapes and designs. The machines produce cuts with high precision and accuracy, resulting in perfect fit without any leaks.3. Aerospace IndustryIn the aerospace industry, fiber laser pipe cutters produce pipes with complex shapes and designs required for engines and hydraulic systems. The high precision and accuracy of the cuts ensure that the pipes fit perfectly, reducing the chances of failure.ConclusionFiber laser pipe cutting machines are the ultimate solution for precision metal pipe cutting. These machines offer high precision, high production speed, reduced labor costs, minimal material wastage, and minimal maintenance requirements. They find applications in numerous fields, including construction, automotive, and aerospace industries. If you plan to engage in metal laser pipe cutting or purchase a pipe laser cutting machine, then a fiber laser pipe cutter should be your top priority.

Top CNC Machinery: Cutting-Edge Technology and Precision Engineering

CNC Machinery Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing industry, CNC machinery has become an essential tool for businesses looking to streamline production processes, increase efficiency, and improve product quality. This advanced technology has significantly transformed the way manufacturers operate, allowing them to achieve higher levels of precision and flexibility in their operations. With the ability to automate complex tasks and produce intricate designs, CNC machinery has become a game-changer in the competitive world of manufacturing.One company that has been at the forefront of this technological revolution is {}. With a strong focus on innovation and cutting-edge solutions, {} has established itself as a leading provider of CNC machinery to a wide range of industries, including automotive, aerospace, medical, and consumer goods. Their state-of-the-art equipment has been instrumental in helping businesses across the globe enhance their production capabilities and stay ahead of the curve.{} offers a comprehensive range of CNC machinery, including machining centers, turning centers, and milling machines, all of which are designed to deliver exceptional performance and reliability. These advanced machines are equipped with the latest control systems, precision tools, and high-speed spindles, allowing users to achieve superior accuracy and consistency in their manufacturing processes. With user-friendly interfaces and intuitive programming, {}'s CNC machinery enables operators to create complex parts and components with ease, making it an invaluable asset for businesses of all sizes.The impact of CNC machinery on the manufacturing industry cannot be overstated. By automating key processes and reducing the margin for human error, these advanced machines have helped businesses increase productivity and efficiency, while also lowering production costs. With the ability to work around the clock and produce high-quality parts with minimal intervention, CNC machinery has become a vital tool for companies looking to stay competitive in today's fast-paced market.In addition to enhancing production capabilities, CNC machinery also offers businesses the flexibility to adapt to changing market demands. With its programmable nature and ability to produce a wide range of parts and components, these machines allow manufacturers to respond quickly to evolving customer needs and industry trends. This level of agility and responsiveness has become a key differentiator for businesses looking to stay ahead in the highly competitive manufacturing landscape.Beyond its immediate impact on production processes, CNC machinery also plays a crucial role in driving innovation and pushing the boundaries of what's possible in manufacturing. With the ability to create complex and intricate designs with unparalleled precision, these advanced machines have opened up new opportunities for businesses to explore and develop novel products and solutions. Whether it's pushing the limits of material science or reimagining traditional manufacturing processes, CNC machinery has become a catalyst for creativity and ingenuity in the industry.Looking ahead, the future of CNC machinery looks brighter than ever. As technology continues to advance and new innovations emerge, the capabilities of these machines are only expected to grow further, opening up new possibilities for manufacturers to explore. From the adoption of artificial intelligence and machine learning to the integration of 3D printing and additive manufacturing, the potential for CNC machinery to drive further advancements in the industry is virtually limitless.In conclusion, CNC machinery has become an indispensable tool for the modern manufacturing industry, revolutionizing the way companies operate and produce goods. Leading providers like {} continue to push the boundaries of what's possible with their state-of-the-art equipment, helping businesses achieve new levels of precision, efficiency, and flexibility in their operations. As the industry continues to evolve, CNC machinery will undoubtedly play a central role in shaping the future of manufacturing.

The Benefits of Plate Laser Technology for Cutting and Engraving

Advanced Laser Technology Revolutionizes Manufacturing IndustryIn a breakthrough for the manufacturing industry, a cutting-edge plate laser technology is set to revolutionize the way companies process and cut metal and other materials. Developed by a leading industrial technology company, this revolutionary plate laser system offers precision cutting capabilities and unmatched efficiency, setting a new standard in the field of laser processing.The introduction of the plate laser system is expected to have a significant impact on various industries, including automotive, aerospace, and industrial manufacturing. With its advanced features and capabilities, this technology is set to streamline production processes, improve quality, and reduce manufacturing costs for companies worldwide.At the core of the plate laser system is its state-of-the-art laser cutting technology, which allows for the precise and efficient cutting of a wide range of materials, including steel, aluminum, and stainless steel. The system is equipped with high-power lasers that can easily handle thick materials with ease, ensuring clean and accurate cuts every time.One of the key advantages of the plate laser system is its ability to perform complex cuts and intricate designs with unparalleled precision. This level of precision and accuracy is crucial for industries that require high-quality parts and components, such as the aerospace and automotive sectors.Furthermore, the plate laser system comes with advanced software and automation features that enable seamless integration with existing manufacturing processes. This not only simplifies the production process but also helps to reduce the risk of errors and increase overall efficiency.In addition to its cutting capabilities, the plate laser system also offers a range of additional features designed to enhance the overall manufacturing process. These include the ability to mark and engrave materials, as well as the option to perform other surface treatments, all within a single system.Moreover, the plate laser system is designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up and utilize the system with minimal training. This ensures a smooth transition for companies looking to integrate this cutting-edge technology into their production facilities.As a result of these advanced features and capabilities, the plate laser system has the potential to significantly improve the competitiveness of companies operating in the manufacturing industry. By enhancing the speed, accuracy, and flexibility of their production processes, companies can stay ahead of the curve and meet the evolving demands of their customers.The introduction of the plate laser system is a testament to the commitment of the company to push the boundaries of innovation and technology in the manufacturing industry. With a strong emphasis on research and development, the company has been at the forefront of developing cutting-edge solutions that address the evolving needs of the market.Through its extensive industry expertise and a dedication to excellence, the company has established itself as a trusted partner for companies seeking to enhance their manufacturing capabilities. With a global presence and a reputation for delivering high-quality solutions, the company is well-positioned to drive the adoption of advanced laser technology in the manufacturing industry.As the manufacturing industry continues to evolve, the demand for advanced technologies that can deliver speed, precision, and efficiency will only continue to grow. With its remarkable plate laser system, the company is paving the way for a new era of manufacturing, where innovation and technology converge to shape the future of production processes.