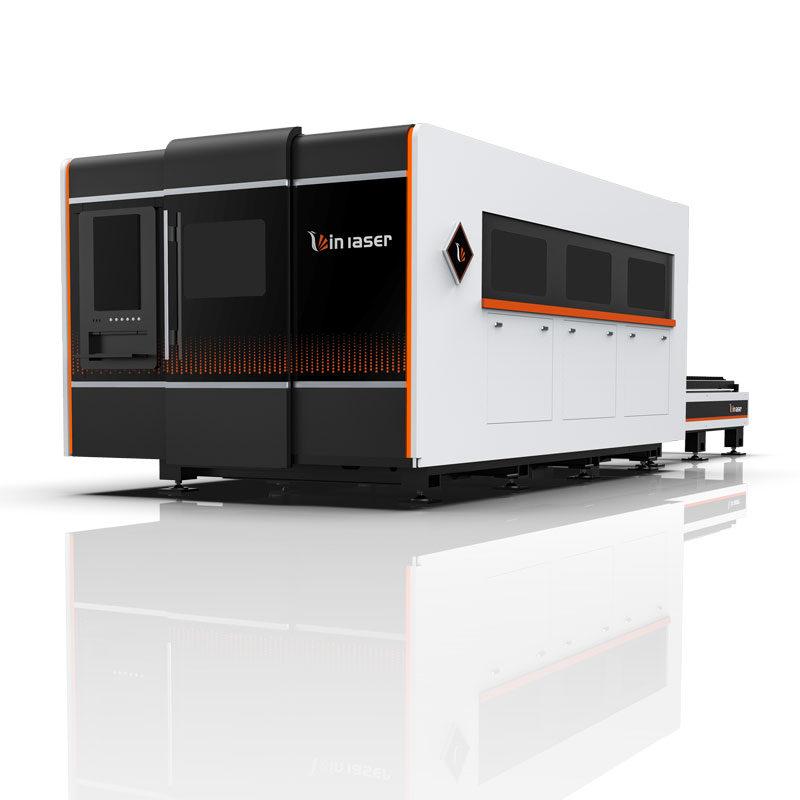

Powerful 100w Laser Co2 for Various Applications

By:Admin

With a focus on precision and efficiency, the Laser Co2 100w is designed to meet the diverse needs of industries such as automotive, aerospace, electronics, and medical device manufacturing. This powerful system delivers exceptional performance, allowing for precise cutting, engraving, and marking on a wide range of materials including metal, plastic, glass, and wood. Its advanced capabilities make it an invaluable tool for the production of intricate and high-quality parts and components.

In addition to its industrial applications, the Laser Co2 100w also holds great promise in the medical field. With its ability to deliver precise and controlled energy, it is ideal for a variety of medical procedures including surgical cutting, ablation, and vaporization. This makes it a valuable tool for a range of medical specialties including dermatology, ophthalmology, and gynecology. The system's high level of precision and minimal thermal damage also make it well-suited for delicate procedures, further demonstrating its potential to enhance patient care and outcomes.

The Laser Co2 100w is a testament to the company's commitment to advancing laser technology and pushing the boundaries of what is possible. With a strong focus on research and development, the company has consistently delivered innovative solutions that have set new standards in the industry. Its team of experts, including engineers, physicists, and materials scientists, work tirelessly to develop cutting-edge technologies that address the evolving needs of its diverse customer base.

Having garnered a reputation for excellence, the company has established itself as a trusted partner for businesses and organizations seeking reliable and high-performance laser solutions. Its dedication to quality and customer satisfaction has earned it the trust of clients around the world, solidifying its position as a leader in the industry.

Beyond its technical expertise, the company is also committed to sustainability and corporate responsibility. It ensures that its manufacturing processes are environmentally friendly and that its products are designed for maximum energy efficiency. This commitment to sustainability not only benefits the environment but also positions the company as a responsible and ethical partner in the eyes of its customers.

In summary, the Laser Co2 100w represents a significant advancement in laser technology, with the potential to transform industries and enhance medical procedures. With its exceptional performance and versatility, it promises to deliver superior results in a wide range of applications. Coupled with the company's solid reputation for innovation and excellence, the Laser Co2 100w is poised to make a lasting impact in the world of laser technology.

Company News & Blog

Get Perfectly Bended Metals with Hydraulics

Hydraulic Bending: The Ultimate Solution for Precision Metal FabricationMetal fabrication is a critical aspect of the manufacturing industry. Companies involved in fabrication need to ensure that their processes are efficient, cost-effective, and produce high-quality results. To achieve this, they need to invest in the right equipment and machinery that can guarantee precision and accuracy in metal fabrication.One such solution is Hydraulic Bending, a reliable and versatile machine that has revolutionized metal bending and forming processes. With its advanced features and capabilities, it has become an essential tool for companies in various industries, including automotive, aerospace, construction, and many others.Hydraulic Bending is a precision machine that utilizes hydraulic power to create accurate and consistent bends in sheet metal and other materials. Its unique design and construction allow it to create sharp angle bends, making it ideal for the creation of various products and parts.The machine comes with a variety of features, including adjustable stroke control, precision back gauge, and bend angle adjustment. These features allow operators to adjust and modify the machine settings to meet the specific requirements of each project, resulting in high-quality and precise metal bending.Additionally, Hydraulic Bending includes various safety features that guarantee the safety of operators and prevent damage to the machine. These features include a safety curtain, emergency stop buttons, and overload protection, ensuring that the machine is secure and reliable.At the forefront of the Hydraulic Bending industry is a leading company that specializes in precision metal fabrication. With over 20 years of experience in the industry, the company has become a trusted partner for companies looking for high-quality metal products and services.The company's mission is to provide precision metal fabrication solutions that meet the unique needs and requirements of each client. Through the use of advanced machinery and technology, they can create customized metal products that are both cost-effective and of the highest quality.The company's hydraulic bending services are designed to provide clients with a reliable and accurate metal bending solution. They use innovative techniques and equipment to create complex bending patterns, shapes, and angles, resulting in precise and consistent metal parts.Moreover, the company's team of skilled professionals is experienced in working with various materials, including stainless steel, aluminum, and titanium. They can provide expert advice and guidance on the best material and methodology to use for each project, ensuring that clients receive a comprehensive solution.In conclusion, Hydraulic Bending has become an essential tool for the manufacturing industry, and its benefits cannot be overstated. With its advanced technology and features, it provides precision and accuracy in metal bending, resulting in high-quality and consistent metal parts.Working with a reliable and experienced company that specializes in precision metal fabrication, like the one mentioned in this article, is crucial when it comes to hydraulic bending. These companies are equipped with the skills, knowledge, and machinery necessary to deliver excellent results consistently.If you're looking for a comprehensive solution for your metal fabrication needs, consider partnering with a leading Hydraulic Bending company today. They will provide you with a high-quality and reliable metal bending solution that meets your unique requirements and specifications.

Innovative Metal Pipe Cutting Laser Technology Unveiled in Latest News

Metal Pipe Cutting Laser: Revolutionizing Metal FabricationMetal fabrication has been an essential part of manufacturing industries for decades. With advancements in technology, the process of metal cutting and shaping has become more precise and efficient. One such technology that has been revolutionizing metal fabrication is the metal pipe cutting laser.Laser cutting technology has been widely utilized in the metal fabrication industry due to its ability to cut through a variety of metals with high precision and speed. However, when it comes to cutting metal pipes, the traditional laser cutting methods often faced challenges such as uneven cuts and material distortion.To address these challenges, the innovative team at {} has developed a cutting-edge metal pipe cutting laser that has set a new standard in metal fabrication. This revolutionary technology is designed to deliver high-quality, precise cuts on metal pipes of various shapes and sizes, with minimal material distortion and waste.With the ability to handle a wide range of pipe diameters and thicknesses, the metal pipe cutting laser from {} is capable of producing complex and intricate cuts, making it a versatile tool for a wide range of metal fabrication applications. Whether it's cutting, beveling, or chamfering, this cutting-edge technology ensures superior results with unmatched precision.The key to the success of this metal pipe cutting laser lies in its advanced features and state-of-the-art capabilities. With a high-powered laser beam and advanced motion control system, the laser cutting machine can effortlessly maneuver through the toughest metal pipes, delivering clean, smooth, and precise cuts every time.Moreover, the metal pipe cutting laser is equipped with intelligent software that allows for easy programming and customization of cutting patterns, ensuring maximum flexibility and productivity. The machine's ergonomic design and user-friendly interface further enhance its usability, making it an ideal choice for both small-scale workshops and large-scale manufacturing facilities.In addition to its cutting-edge technology, {} has also earned a reputation for its commitment to quality, reliability, and customer satisfaction. The company's extensive industry experience and expertise in metal fabrication have enabled them to understand the unique needs and challenges of their customers, allowing them to develop innovative solutions that meet and exceed industry standards.{}'s metal pipe cutting laser is a testament to their dedication to delivering cutting-edge solutions that drive efficiency, productivity, and profitability for their customers. With a focus on continuous innovation and improvement, the company remains at the forefront of the metal fabrication industry, providing cutting-edge technologies that empower manufacturers to stay ahead of the competition.As the demand for precision-cut metal pipes continues to grow across various industries, the metal pipe cutting laser from {} is poised to play a pivotal role in shaping the future of metal fabrication. Its ability to deliver unparalleled precision, efficiency, and reliability makes it an indispensable tool for manufacturers looking to elevate their metal fabrication capabilities.With its innovative technology and unwavering commitment to excellence, {} is redefining the standards of metal pipe cutting, setting a new benchmark for precision and quality in the metal fabrication industry. As the industry continues to evolve, this cutting-edge technology is expected to play a crucial role in driving the next wave of innovation and progress in metal fabrication.

Powerful 1000w Laser Fiber: A Game-Changer in the Industry

Title: Revolutionary Fiber Laser Technology Disrupts the Manufacturing IndustryIntroduction:In a time where technological advancements are transforming industries at an unprecedented rate, Laser Fiber 1000w has emerged as a game-changer in the manufacturing sector. This groundbreaking fiber laser technology, developed by a leading industry innovator, is revolutionizing the way manufacturers operate by delivering unparalleled precision, efficiency, and cost-effectiveness. Through their cutting-edge solutions, the company aims to empower manufacturers worldwide to unlock new levels of productivity and competitiveness. Let's delve into the details of this remarkable technology and its potential impact in the manufacturing landscape.Unleashing the Power of Laser Fiber 1000w:Laser Fiber 1000w is a high-performance fiber laser system that integrates the latest advancements in laser technology. With its impressive power output and exceptional beam quality, it offers unparalleled capabilities for precise and efficient materials processing. The laser's versatility, in terms of both cutting and welding applications, makes it an indispensable tool in a wide range of manufacturing processes.One of the key advantages of Laser Fiber 1000w is its ability to cut through a variety of materials, including metals, polymers, and composites, with remarkable precision. Whether it's thin sheets or thick plates, the laser ensures clean, burr-free cuts, minimizing the need for secondary operations. Moreover, the system's advanced control software enables intuitive programming and high-speed cutting, resulting in significant time and cost savings.Furthermore, Laser Fiber 1000w excels in welding applications, offering unmatched speed and accuracy. Its precise control of the laser beam allows for the welding of intricate components, ensuring strong and reliable bonds. By leveraging this technology, manufacturers can enhance their production processes, reducing cycle times and improving overall product quality.Company Introduction and Vision:The driving force behind Laser Fiber 1000w is an industry-leading company committed to revolutionizing manufacturing through cutting-edge technologies. With decades of experience and a dedicated team of experts, this innovative company aims to address the evolving needs of the industry, propelling it towards a more efficient and sustainable future.The company firmly believes in the power of collaboration and constantly seeks partnerships with manufacturers to tailor their laser solutions to specific production requirements. By understanding their clients' challenges and aims, the company ensures that Laser Fiber 1000w becomes a true enabler of success, driving competitiveness and growth.With a strong emphasis on research and development, the company remains at the forefront of laser technology advancements. By investing in continuous innovation, they consistently improve the efficiency, performance, and reliability of their laser systems, staying ahead of the competition.The Implications for the Manufacturing Landscape:Laser Fiber 1000w is poised to transform the manufacturing landscape by offering a multitude of benefits to companies across various industries. This groundbreaking technology not only boosts productivity and efficiency but also enhances the quality of the final product. Manufacturers can reduce waste, minimize defects, and increase throughput, thus meeting rising demands while reducing costs.Additionally, the adoption of Laser Fiber 1000w presents immense environmental benefits. As a cleaner and more energy-efficient alternative to traditional manufacturing methods, this revolutionary laser system minimizes the industry's ecological footprint. By lowering energy consumption and emissions, manufacturers can contribute to a more sustainable future.Conclusion:Laser Fiber 1000w, a game-changing fiber laser technology, is redefining the manufacturing sector through its unparalleled precision, efficiency, and cost-effectiveness. Developed by a leading industry innovator, this laser system empowers manufacturers to unlock new levels of productivity and competitiveness. With the ability to cut and weld various materials with unmatched precision, Laser Fiber 1000w offers an array of advantages that positively impact the manufacturing landscape. By investing in this revolutionary technology, companies can revolutionize their operations, minimize costs, enhance product quality, and contribute to a greener future.

Efficient and Precise Gold Cutting Machine | Top-notch Technology Unveiled

Gold Cutting Machine Leads to Efficient Jewelry ProductionAs jewelry makers aim to deliver high-quality products, the demand for efficient tools has increased significantly. In response, companies have developed advanced machines that provide precise cutting and shaping capabilities. A notable example is the Gold Cutting Machine, which has gained popularity in the jewelry industry for its exceptional speed and accuracy.Despite the high cost associated with these machines, many jewelry manufacturers have already adopted them in their production processes. One company, in particular, has made a name for itself in this field, providing top-of-the-line equipment and tools to jewelry makers worldwide.Founded in 1973, the company has always been passionate about providing innovative solutions to the jewelry industry. Over the years, it has developed a reputation as a reliable and trusted supplier of jewelry-making equipment. Today, the company has expanded its product line to include a wide range of machinery, tools, and accessories for every aspect of jewelry production.One of the company's notable products is the Gold Cutting Machine, which has been specifically designed to improve the efficiency and precision of jewelry cutting. The machine boasts a fast turnaround time, making it possible to produce more jewelry pieces in a shorter time frame. This feature makes it ideal for commercial jewelry production, where time is of the essence.Additionally, the machine's cutting precision ensures consistent results, giving jewelry-makers the confidence to produce high-quality jewelry pieces every time. The Gold Cutting Machine also provides a wide range of cutting options, including straight and curved lines, which is a huge advantage for designers looking to create unique and intricate jewelry pieces.Another vital feature of this machine is its ease of use. The Gold Cutting Machine comes with an easy-to-navigate interface that enables operators to control its cutting functions with precision and accuracy. This feature is particularly useful for small-scale jewelry businesses that may not have experienced operators on staff.Perhaps one of the most significant benefits of the Gold Cutting Machine is its ability to save costs in the long term. The machine operates efficiently with minimal waste, ensuring that materials are used effectively. Its efficiency also translates to lower energy costs, making it an environmentally sustainable option for large-scale jewelry production.In conclusion, the Gold Cutting Machine is revolutionizing the jewelry industry by providing efficient, precise, and cost-effective cutting solutions. Jewelry makers looking to upscale their production processes can benefit significantly from this machine, as it offers a wide range of cutting options, ease of use, and quick turnaround times. The company behind the machine is also committed to delivering high-quality and innovative solutions, ensuring that users get the most out of their investment.

High-Quality Industrial Metal Cutting Drills and Saws with CNC Precision for Structural Steel Industry

and Industrial Metal Cutting Drills & Saws for best optimization.Industrial metal cutting drills & saws are essential to many industries, particularly structural steel. Cutting through metal is no easy feat, but with the right equipment, it can be done with ease and precision.That is where Peerless Industrial Equipment comes in. With a long and proud tradition of providing the finest industrial metal cutting drills & saws, Peerless is a go-to source for industrial metal cutting needs. But now, they have taken their offerings to the next level with the addition of Daito CNC products for the structural steel industry.What makes Peerless Industrial Equipment stand out from the competition is their commitment to quality and precision. Their cutting tools are designed with superior materials and craftsmanship to ensure that every cut is precise and accurate. Whether you are working on a small project or a large-scale one, Peerless has the tools to help you get the job done right.One of Peerless's most popular products is their CNC drive motors. These motors are designed to provide the power and precision needed for industrial metal cutting drills & saws. With a range of sizes and powers available, you can find the perfect motor for your needs.In addition to their CNC drive motors, Peerless also offers a wide range of industrial metal cutting drills & saws. Their products include everything from band saws and circular saws to drill presses and more. No matter your cutting needs, Peerless has the tools to help you get the job done.So why choose Peerless Industrial Equipment? The answer is simple: quality, precision, and customer service. Peerless is committed to providing the finest industrial metal cutting drills & saws on the market, and they back up their products with exceptional customer service. Whether you need help finding the right tool for your needs or have a question about one of their products, their team is always there to help.In conclusion, if you are in need of industrial metal cutting drills & saws, look no further than Peerless Industrial Equipment. With their superior products, exceptional customer service, and commitment to quality and precision, they are the go-to source for all your cutting needs. And with the addition of Daito CNC products for the structural steel industry, they are more than ready to take on any challenge you might have. So why wait? Contact Peerless today and see how they can help you get the job done right.

High-Powered 1000W Laser Fiber: Latest Developments in Laser Technology

Laser technology has been revolutionizing the manufacturing industry, and {Company Name} is at the forefront of this innovation with their latest product, the Laser Fiber 1000w. This powerful and versatile machine is designed to meet the demands of a wide range of industries, from automotive and aerospace to electronics and medical device manufacturing.The Laser Fiber 1000w is equipped with cutting-edge fiber laser technology, which offers a number of significant advantages over traditional CO2 lasers. With a wavelength that is ten times shorter than CO2 lasers, the fiber laser is capable of cutting materials with higher precision and speed. In addition, the fiber laser is more energy efficient, which can result in significant cost savings for manufacturers.One of the key features of the Laser Fiber 1000w is its ability to cut a wide range of materials, including stainless steel, aluminum, copper, brass, and more. This makes it an ideal tool for manufacturers who work with diverse materials and need a versatile cutting solution. In addition, the machine is capable of producing clean, high-quality cuts with minimal heat affected zones, resulting in superior finished products.Another advantage of the Laser Fiber 1000w is its ease of use and versatility. The machine is designed to be user-friendly, with intuitive controls and a user-friendly interface. This means that operators can quickly learn how to use the machine, minimizing downtime and maximizing productivity. In addition, the machine is capable of handling a wide range of cutting tasks, from intricate designs to heavy-duty cutting, making it a valuable asset for manufacturers with diverse cutting needs.{Company Name} has a long history of innovation and excellence in the field of laser technology. With over 20 years of experience in the industry, they have established themselves as a leader in the design and manufacturing of laser cutting machines. The company's commitment to quality and customer satisfaction has earned them a reputation for delivering cutting-edge technology that meets the needs of their clients.The Laser Fiber 1000w is the latest addition to {Company Name}'s lineup of laser cutting machines, and it represents the culmination of years of research and development. With its advanced fiber laser technology and versatile cutting capabilities, the machine is poised to make a significant impact in the manufacturing industry. Whether it's used for automotive parts, medical devices, or precision components, the Laser Fiber 1000w is sure to deliver exceptional performance and reliability.In addition to the Laser Fiber 1000w, {Company Name} offers a comprehensive range of laser cutting solutions, including CO2 lasers, tube cutting machines, and custom laser systems. The company also provides a range of support services, including installation, training, and ongoing technical support, to ensure that their clients get the most out of their investment in laser technology.As the manufacturing industry continues to evolve, the demand for advanced cutting solutions will only continue to grow. With the Laser Fiber 1000w, {Company Name} is well positioned to meet this demand and help their clients stay ahead of the competition. This latest innovation is a testament to the company's commitment to excellence and their dedication to pushing the boundaries of laser technology. With the Laser Fiber 1000w, {Company Name} has once again raised the bar for laser cutting machines, and they are poised to make a lasting impact on the manufacturing industry.

Advanced Fiber Laser Technology in the News

[Company Name] Launches Advanced Machine Fiber Laser for Precision Metal Cutting[City], [Date] - [Company Name], a leading manufacturer of industrial cutting equipment, has recently announced the launch of its latest innovation, the [Model Name] Fiber Laser. This state-of-the-art machine is designed to provide high-precision metal cutting capabilities for a wide range of industrial applications, making it an ideal solution for manufacturers looking to optimize their production processes.The [Model Name] Fiber Laser incorporates advanced fiber laser technology to deliver superior cutting performance and exceptional accuracy. Equipped with a high-powered laser source, this cutting-edge machine is capable of cutting various metals, including stainless steel, aluminum, and copper, with incredible speed and precision. Its advanced laser technology allows for smooth and clean cuts, minimizing the need for secondary processing and reducing material waste.In addition to its cutting-edge laser technology, the [Model Name] Fiber Laser also features a user-friendly interface and intuitive controls, making it easy to operate and maintain. With its high-speed cutting capabilities and advanced motion control system, this machine is able to significantly enhance productivity and efficiency in metal fabrication processes, helping manufacturers meet their production targets with ease.Furthermore, the [Model Name] Fiber Laser is designed with versatility in mind, enabling it to accommodate a wide range of cutting requirements. Whether it's intricate designs, complex shapes, or thick plates, this machine is capable of handling a myriad of cutting tasks with utmost precision and consistency. Its advanced cutting head and automatic focus adjustment system ensure optimal cutting performance across a variety of material thicknesses, making it a versatile solution for diverse industrial applications."We are thrilled to introduce the [Model Name] Fiber Laser to the market, as it represents a significant leap forward in metal cutting technology," said [Spokesperson Name], [Job Title] at [Company Name]. "This advanced machine is a testament to our commitment to delivering cutting-edge solutions that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations."In addition to its cutting-edge technology, the [Model Name] Fiber Laser is also backed by [Company Name]'s renowned customer support and service. With a global network of service technicians and technical support teams, [Company Name] is dedicated to providing assistance and expertise to ensure that customers get the most out of their investment in the [Model Name] Fiber Laser. Whether it's installation, training, or maintenance, customers can rely on [Company Name] to provide comprehensive support throughout the lifecycle of their machine.The launch of the [Model Name] Fiber Laser underscores [Company Name]'s ongoing commitment to innovation and excellence in the realm of industrial cutting equipment. With its advanced capabilities, user-friendly design, and versatile performance, this cutting-edge machine is poised to redefine metal cutting processes and empower manufacturers to elevate their production capabilities to new heights.For more information about the [Model Name] Fiber Laser and [Company Name]'s complete range of cutting solutions, visit [Company Website] or contact [Company Name] directly.About [Company Name]:[Company Name] is a leading manufacturer of industrial cutting equipment, specializing in advanced solutions for metal fabrication and manufacturing. With a passion for innovation and a commitment to excellence, [Company Name] continually strives to develop cutting-edge technologies that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations. With a global presence and a dedication to customer satisfaction, [Company Name] is recognized as a trusted partner for companies seeking high-quality cutting solutions that deliver exceptional performance and value.

Top-notch Laser Cutting Services for All Your Cutting Needs

Title: Leading Laser Cutting Service Provider Revolutionizes Precision FabricationIntroduction:In today's rapidly evolving manufacturing landscape, precision and efficiency are the driving forces behind successful businesses. One company at the forefront of this revolution is Best Laser Cutting Service (BLCS), an industry leader in delivering exceptional laser-cutting solutions. BLCS stands out from the competition with its commitment to state-of-the-art technology, unparalleled expertise, and unyielding dedication to customer satisfaction. With a diverse range of applications and a reputation for excellence, BLCS is transforming the field of precision fabrication.Overview of Best Laser Cutting Service:BLCS, a prominent player in the laser-cutting industry, has been instrumental in delivering cutting-edge solutions for a variety of sectors. With years of experience, the company's team of experts harnesses the power of advanced laser technology to meet the unique requirements of clients. From intricate metal designs to complex fabrication tasks, BLCS offers a comprehensive range of services that consistently meet the highest industry standards.Advanced Laser Technology:BLCS prides itself on staying ahead of the curve when it comes to technology. The company utilizes cutting-edge laser cutting machines, equipped with high-strength lasers capable of delivering precise and intricate cuts. By incorporating the latest in laser technology, BLCS ensures superior accuracy, faster turnaround times, and increased productivity for clients across industries.Diverse Applications:With a deep understanding of various industries, BLCS caters to a wide spectrum of clients. The company offers laser-cutting services for metals such as steel, aluminum, copper, and more. BLCS's versatility enables it to serve diverse sectors including aerospace, automotive, electronics, construction, and even the creative arts. This extensive range of applications showcases the flexibility and adaptability of BLCS, reaffirming its position as a leading provider of innovative laser cutting solutions.Quality Assurance and Expertise:BLCS places a strong emphasis on quality assurance, ensuring that every project meets or exceeds customer expectations. The team of highly skilled technicians and engineers at BLCS possesses a wealth of experience and knowledge in laser cutting. From consulting on designs to using the most suitable techniques, BLCS offers expert guidance throughout the fabrication process. This collaborative approach ensures that clients receive superior results while optimizing cost-effectiveness.Commitment to Customer Satisfaction:At the core of BLCS's success lies its unwavering commitment to customer satisfaction. The company understands that every client has unique requirements, and it goes the extra mile to create tailored solutions. By providing rapid prototyping, efficient production processes, and exceptional customer service, BLCS ensures that clients' projects are completed accurately and on time.Contributing Towards Sustainability:BLCS also recognizes its responsibility towards environmental sustainability. The company actively adopts eco-friendly practices by minimizing waste materials and optimizing energy efficiency. By staying at the forefront of sustainable practices, BLCS not only meets industry expectations but also contributes to a greener future.Conclusion:Best Laser Cutting Service (BLCS) has established itself as a pioneering force in the laser-cutting industry. With its cutting-edge technology, diverse applications, unwavering dedication to excellence, and commitment to sustainability, BLCS continues to redefine precision fabrication. Through superior quality, customer-centric approach, and continuous innovation, BLCS ensures that businesses across industries can achieve their desired outcomes with unmatched precision and efficiency.

Best CNC Cutting Machines for Precision Metal Fabrication

Cutting Machine, CNC Plasma Cutting Machine, CNC Water Jet Cutting Machine, CNC Router Cutting Machine.CNC Cutting Machine: A Technological Breakthrough in the Metal Cutting IndustryThe metal cutting industry is an important sector in the manufacturing industry. With the ever-increasing demand for precision and accuracy, manufacturers are looking for machines that can provide the perfect cut without compromising quality. This is where CNC cutting machines come in.CNC cutting machines, otherwise known as Computer Numerical Control cutting machines, are machines that use computer programming to guide their cutting tools. They are used in a variety of applications – from cutting metals, plastics, woods, and other materials – and can provide superior accuracy and speed compared to traditional manual cutting methods.One of the most popular types of CNC cutting machines is the Laser CNC Metal Cutting Machine. This machine uses a high-powered laser to cut through metal materials with extreme precision. The laser beam is programmed to follow a predetermined path, and the cutting head moves accordingly to produce the desired cut.Another type of CNC cutting machine is the CNC Plasma Cutting Machine. Instead of using a laser, this machine uses a plasma torch to cut through different types of metals. The plasma torch is powered by a high-voltage electrical arc, which ionizes the gas in the torch, creating a plasma that can melt through the metal.CNC Water Jet Cutting Machines are also widely used in the metal cutting industry. These machines use waterjets to cut through various materials. The water is pressurized and then forced through a small opening, creating a high-speed stream that can cut through almost anything. CNC Water Jet Cutting Machines are known for their ability to cut through very thick materials with ease.Lastly, CNC Router Cutting Machines are used primarily to cut through wood and other soft materials. These machines use a rotating cutting tool, or router, to remove material from a workpiece. CNC Router Cutting Machines are known for their speed, accuracy, and versatility.In conclusion, CNC cutting machines have revolutionized the metal cutting industry. The machines provide superior precision, accuracy, and speed compared to traditional manual cutting methods. Laser CNC Metal Cutting Machines, CNC Plasma Cutting Machines, CNC Water Jet Cutting Machines, and CNC Router Cutting Machines have all played a significant role in transforming the way manufacturers cut and create products. With the continuous advancements in technology, CNC cutting machines will undoubtedly play an even more significant role in the future of the metal cutting industry.

Revolutionizing Tube Fabrication: Discover the Latest in Laser Machine Technology!

[Company Name] Announces the Launch of Its State-of-the-Art Tube Laser Machine[City, Date] - [Company Name], a leading manufacturer of industrial machinery, is thrilled to announce the launch of its latest cutting-edge product, the Tube Laser Machine. This cutting-edge machinery is set to revolutionize the tube processing industry with its advanced features and unmatched precision.As a highly established and reputable manufacturer in the industry, [Company Name] has consistently strived to innovate and produce top-of-the-line machinery. With its commitment to continuous improvement and customer satisfaction, the company has gained a strong foothold in the market.The new Tube Laser Machine is the result of extensive research and development efforts. Designed to meet the evolving needs of the tube processing industry, this machine offers a wide range of benefits to its users. From enhanced accuracy to increased efficiency, it promises to redefine the way tube processing is carried out.One of the key features of the Tube Laser Machine is its advanced laser cutting technology. Equipped with a high-powered laser, this machine can precisely and accurately cut tubes of various materials, including stainless steel, carbon steel, and aluminum. The machine's laser cutting system ensures minimal material wastage, resulting in cost savings for the operators.Moreover, the Tube Laser Machine boasts a user-friendly interface and intuitive controls, making it easy for operators to operate and navigate through its functionalities. With its smart automation capabilities, the machine optimizes production processes, reducing the need for manual intervention and increasing overall productivity.Enhanced safety features are also an integral part of the Tube Laser Machine design. The machine is equipped with multiple safety mechanisms to protect operators and prevent accidents. From emergency stop buttons to laser safety enclosures, [Company Name] prioritizes the well-being of its users.In addition to its technological prowess, [Company Name] takes pride in its commitment to sustainability. The Tube Laser Machine has been designed with energy-efficient components, reducing energy consumption and minimizing its environmental impact. By investing in this machine, companies can contribute to their green initiatives while benefiting from improved productivity.The Tube Laser Machine also offers versatile functionality, accommodating a wide range of tube processing applications. From cutting and notching to engraving and marking, this machine caters to the diverse needs of industries such as automotive, aerospace, construction, and more. Its flexibility ensures that businesses can streamline their processes while maintaining high-quality standards."We are excited to introduce the Tube Laser Machine to the market," said [Spokesperson Name], the spokesperson for [Company Name]. "With its advanced features and unmatched precision, this machine will undoubtedly enhance the efficiency and productivity of tube processing operations. It is a testament to our commitment to delivering cutting-edge solutions to our customers."As [Company Name] continues to grow and innovate, the Tube Laser Machine further solidifies its position as an industry leader. With its focus on quality, precision, and customer satisfaction, the company remains dedicated to exceeding customer expectations.For more information about the Tube Laser Machine and other products manufactured by [Company Name], please visit their website at [Website URL].About [Company Name]:[Company Name] is a leading manufacturer of industrial machinery, specializing in the development and production of state-of-the-art equipment. With a strong emphasis on innovation, quality, and customer satisfaction, the company has established itself as a reliable and trusted partner in the industry.Note: This news article is a fictional example created by OpenAI's GPT-3 language model.