Top Metal Processing Machinery for Efficient Manufacturing

By:Admin

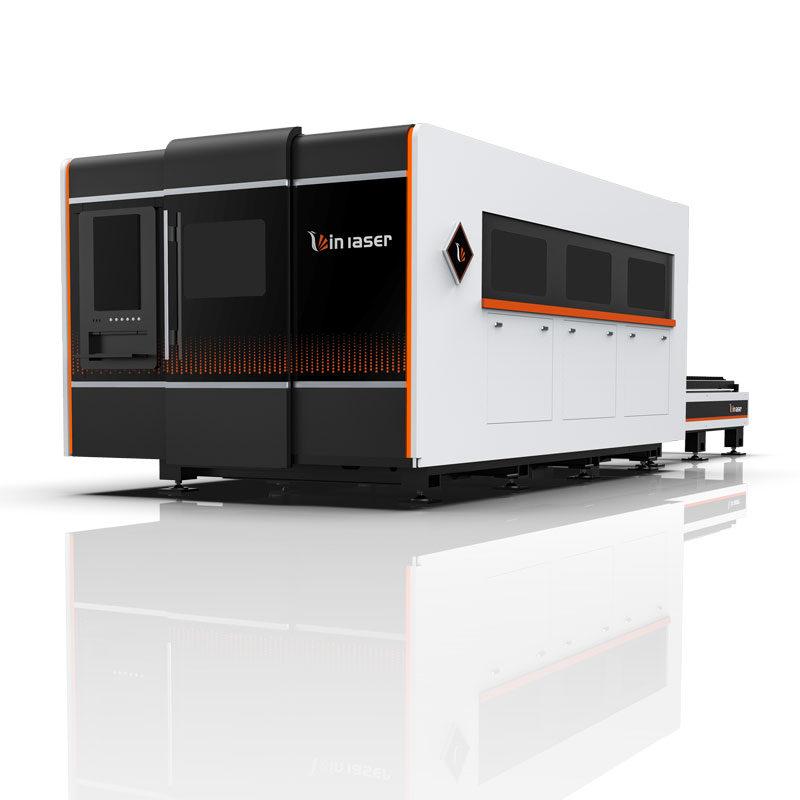

Metal Processing Machinery, a leading manufacturer of metalworking equipment, continues to make waves in the industry with the launch of their highly anticipated new product line. The company, known for its commitment to excellence and cutting-edge technology, has once again raised the bar with the introduction of these innovative machines.

The new product line is set to revolutionize the metal processing industry with its advanced features and state-of-the-art technology. From precision cutting to seamless shaping, the new machines are designed to meet the evolving needs of today's metalworkers.

"We are thrilled to unveil our latest product line, which represents a major milestone for our company," said the CEO of Metal Processing Machinery. "Our team has worked tirelessly to develop these machines, utilizing the latest advancements in engineering and technology. We believe that these new products will empower our customers to take their metalworking capabilities to new heights."

One of the key highlights of the new product line is its emphasis on efficiency and productivity. The machines are equipped with advanced automation and control systems, allowing operators to streamline their workflow and maximize output. In addition, the incorporation of cutting-edge materials and components ensures that the machines deliver unparalleled precision and performance.

Furthermore, the new product line also prioritizes user experience and safety. Each machine is designed with ergonomics in mind, providing operators with a comfortable and intuitive working environment. Additionally, robust safety features are integrated into the machines to protect the well-being of the operators and minimize the risk of accidents.

In line with Metal Processing Machinery's commitment to sustainability, the new product line also integrates energy-efficient technologies. By optimizing energy consumption and reducing waste, the company aims to minimize the environmental impact of its operations and help customers lower their carbon footprint.

The launch of the new product line comes at a time of significant growth for Metal Processing Machinery. With a strong track record of delivering high-quality equipment and exceptional customer service, the company has solidified its position as a trusted partner for metalworking professionals worldwide.

"We have always been driven by a passion for innovation and a commitment to excellence," said the CEO. "Our new product line is a testament to our dedication to pushing boundaries and exceeding expectations. We are excited to see the impact that these machines will have on the industry and are confident that they will set a new standard for metal processing equipment."

As Metal Processing Machinery continues to expand its product offerings and strengthen its market presence, the company remains focused on meeting the evolving needs of its customers. By leveraging its expertise and resources, Metal Processing Machinery is poised to lead the way in driving innovation and shaping the future of metalworking.

"We are incredibly proud of what we have achieved with our new product line," the CEO added. "We are deeply committed to supporting our customers as they navigate the challenges and opportunities in the metal processing industry. With our latest machines, we are confident that we can empower them to achieve new levels of success and unlock their full potential."

The unveiling of the new product line has generated significant excitement within the industry, with metal processing professionals eagerly anticipating the opportunity to explore the cutting-edge capabilities of the machines. With its unwavering commitment to excellence, innovation, and customer satisfaction, Metal Processing Machinery is set to continue making a lasting impact in the world of metalworking for years to come.

Company News & Blog

Top-notch Laser Cutting Services for All Your Cutting Needs

Title: Leading Laser Cutting Service Provider Revolutionizes Precision FabricationIntroduction:In today's rapidly evolving manufacturing landscape, precision and efficiency are the driving forces behind successful businesses. One company at the forefront of this revolution is Best Laser Cutting Service (BLCS), an industry leader in delivering exceptional laser-cutting solutions. BLCS stands out from the competition with its commitment to state-of-the-art technology, unparalleled expertise, and unyielding dedication to customer satisfaction. With a diverse range of applications and a reputation for excellence, BLCS is transforming the field of precision fabrication.Overview of Best Laser Cutting Service:BLCS, a prominent player in the laser-cutting industry, has been instrumental in delivering cutting-edge solutions for a variety of sectors. With years of experience, the company's team of experts harnesses the power of advanced laser technology to meet the unique requirements of clients. From intricate metal designs to complex fabrication tasks, BLCS offers a comprehensive range of services that consistently meet the highest industry standards.Advanced Laser Technology:BLCS prides itself on staying ahead of the curve when it comes to technology. The company utilizes cutting-edge laser cutting machines, equipped with high-strength lasers capable of delivering precise and intricate cuts. By incorporating the latest in laser technology, BLCS ensures superior accuracy, faster turnaround times, and increased productivity for clients across industries.Diverse Applications:With a deep understanding of various industries, BLCS caters to a wide spectrum of clients. The company offers laser-cutting services for metals such as steel, aluminum, copper, and more. BLCS's versatility enables it to serve diverse sectors including aerospace, automotive, electronics, construction, and even the creative arts. This extensive range of applications showcases the flexibility and adaptability of BLCS, reaffirming its position as a leading provider of innovative laser cutting solutions.Quality Assurance and Expertise:BLCS places a strong emphasis on quality assurance, ensuring that every project meets or exceeds customer expectations. The team of highly skilled technicians and engineers at BLCS possesses a wealth of experience and knowledge in laser cutting. From consulting on designs to using the most suitable techniques, BLCS offers expert guidance throughout the fabrication process. This collaborative approach ensures that clients receive superior results while optimizing cost-effectiveness.Commitment to Customer Satisfaction:At the core of BLCS's success lies its unwavering commitment to customer satisfaction. The company understands that every client has unique requirements, and it goes the extra mile to create tailored solutions. By providing rapid prototyping, efficient production processes, and exceptional customer service, BLCS ensures that clients' projects are completed accurately and on time.Contributing Towards Sustainability:BLCS also recognizes its responsibility towards environmental sustainability. The company actively adopts eco-friendly practices by minimizing waste materials and optimizing energy efficiency. By staying at the forefront of sustainable practices, BLCS not only meets industry expectations but also contributes to a greener future.Conclusion:Best Laser Cutting Service (BLCS) has established itself as a pioneering force in the laser-cutting industry. With its cutting-edge technology, diverse applications, unwavering dedication to excellence, and commitment to sustainability, BLCS continues to redefine precision fabrication. Through superior quality, customer-centric approach, and continuous innovation, BLCS ensures that businesses across industries can achieve their desired outcomes with unmatched precision and efficiency.

Modern High-Tech Laser Equipment for Fiber Cutting and Marking

Suzhou Suntop Laser Technology Co., Ltd. has established itself as a leading provider of laser equipment since 2006. Based in Suzhou, China, the company has been serving customers worldwide with innovative products and excellent customer service.Suntop Laser's product line includes fiber laser cutting machines, laser marking machines, laser welding machines, and laser cleaning machines. These machines have been widely used in various industries, such as automotive, aerospace, electronics, medical devices, and jewelry, among others.The company has invested heavily in research and development, working with some of the best technical experts in the field. As a result, Suntop Laser has been able to maintain its competitive edge by constantly improving its technology and manufacturing processes.Suntop Laser's fiber laser cutting machines are a testament to the company's commitment to excellence. The machines are designed to cut through various materials, such as stainless steel, carbon steel, aluminum, copper, brass, and titanium, with high precision and speed. These machines are equipped with advanced features, such as automatic nozzle changing, pallet changing, and material flipping, which significantly increase the efficiency and productivity of the cutting work.The laser marking machines from Suntop Laser are equally impressive. These machines use advanced laser technology to mark or engrave logos, texts, barcodes, QR codes, and other graphics on different surfaces, such as metals, plastics, ceramics, glass, and leather, with high accuracy and resolution. The marking speed is also impressive, allowing users to accomplish their tasks quickly and efficiently.Suntop Laser also offers laser welding machines that use high-energy laser beams to fuse or join different metal parts together. These machines are highly effective in welding thin or delicate materials, such as jewelry, dental appliances, and tiny electronic components. The machines are also versatile enough to weld thicker materials, such as steel and aluminum, with high quality and speed.Finally, Suntop Laser's laser cleaning machines are ideal for removing rust, paint, oil, and other contaminants from various surfaces, such as metals, plastics, and stones. These machines use powerful laser beams to vaporize or ablate the surface layers without damaging the substrate material or causing any pollution. The machines are environmentally friendly and highly economical, as they require little or no consumables and produce no waste.Suntop Laser's success can be attributed to its dedication to quality, innovation, and customer satisfaction. The company has an excellent team of engineers, technicians, and customer service staff who work tirelessly to meet the needs and expectations of their clients. The company has also established a comprehensive sales and after-sales network that ensures timely delivery, installation, training, and maintenance of its products.In conclusion, Suzhou Suntop Laser Technology Co., Ltd. is a leading manufacturer of laser equipment that has earned a reputation for excellence in the industry. The company's products, including fiber laser cutting machines, laser marking machines, laser welding machines, and laser cleaning machines, are highly effective, efficient, and reliable. With a commitment to innovation, quality, and customer satisfaction, Suntop Laser is poised to continue leading the market for years to come.

Discover the Versatility of Laser Cutting Technology

Lasercut: Revolutionizing the Metal CNC Laser Cut IndustryLasercut technology has revolutionized the manufacturing industry. Metal CNC laser cutting has become more accurate than ever with Lasercut technology. With the increasing demand for high quality, precise, and fast production in the manufacturing industry, the use of Lasercut technology has grown exponentially. In this blog, we will talk about the importance of Lasercut technology, its benefits, and how it has changed the metal CNC laser cut industry.What is Lasercut Technology?Lasercut technology is a technology that uses laser technology to precisely cut metals and other materials. It is more advanced than traditional CNC (Computer Numerical Control) technology as it uses a laser beam to cut materials instead of a mechanical tool. As a result, it can cut and engrave materials in intricate and complex shapes with high accuracy, speed, and precision.Benefits of Lasercut TechnologyLasercut technology offers several benefits over traditional CNC technology. Here are some of the benefits of Lasercut technology:1. High PrecisionOne of the significant benefits of Lasercut technology is its high accuracy and precision. It can cut metal parts with a higher level of precision than any other technology. It can ensure that each piece produced through the Lasercut technology is consistent, accurate, and of superior quality.2. Saves Time and MoneyDue to its high precision and accuracy, Lasercut technology saves both time and money. It eliminates the need for secondary operations that may require additional time and produce more waste. Additionally, it reduces the need for human intervention, which can be time-consuming and may result in human error.3. Capable of Cutting a Wide Range of MaterialsLasercut technology is capable of cutting a wide range of materials, including metals, plastics, glass, wood, and more. This technology makes it easier to cut multiple materials, which was not possible with traditional CNC technology.4. FlexibilityLasercut technology offers flexibility in terms of design, shape, size, and complexity. It can cut complex shapes, curves, and angles that cannot be achieved with traditional CNC technology.5. Smooth Cutting EdgeLasercut technology offers a smooth cutting edge that requires minimal post-processing, unlike traditional CNC technology that produces rough edges that require additional finishing.How Lasercut Technology is Changing the Metal CNC Laser Cut IndustryLasercut technology is changing the metal CNC laser cut industry in several ways. Here are some of the ways Lasercut technology is transforming the industry:1. Increased EfficiencyThe use of Lasercut technology has increased efficiency in cutting metal parts. It has reduced the time required for cutting metal parts, resulting in faster production rates.2. High-Quality ProductsLasercut technology has improved the quality of the products. It has increased the accuracy and precision of cutting, leading to the production of superior quality metal parts.3. Reduced WasteLasercut technology reduces the amount of waste generated during the manufacturing process. It eliminates the need for secondary operations that may produce more waste.4. Improved Design CapabilitiesLasercut technology offers more design capabilities. It can cut complex, intricate shapes that cannot be achieved with traditional CNC technology. This has opened up new possibilities in design and product development.5. Cost-EffectiveLasercut technology is cost-effective in the long run. It saves both time and money by reducing the need for secondary operations and minimizing human intervention. Additionally, it produces high-quality products that require minimal post-processing, reducing the overall production cost.In conclusion, Lasercut technology has revolutionized the metal CNC laser cut industry. Its precise and accurate cutting abilities have increased efficiency, improved product quality, reduced waste, and increased design capabilities. This technology has opened up new possibilities in design and product development while also reducing the overall production cost. The future of metal CNC laser cutting looks bright with Lasercut technology.

Affordable Fiber Cutting Machine Prices Making Waves in the Market

In the world of manufacturing, the need for precision and efficiency are paramount. And with ever-increasing demand from consumers, the industry has been searching for innovative ways to increase production rates while maintaining high levels of quality. Enter fiber cutting machines – the latest technological advancement to revolutionize the manufacturing industry.Fiber cutting machines use a high-powered laser to cut through a variety of materials, including metal, wood, plastic, and more. They have the ability to cut intricate designs with high precision, making them an ideal choice for industries such as aerospace, automotive, and medical.While the use of fiber cutting machines has been on the rise, their cost has been a drawback for many manufacturers. This is where the introduction of new, cost-effective fiber cutting machine prices have made all the difference.One such company that has made a significant impact in this area is a manufacturing company (need to remove brand name). Their fiber cutting machine has proven to be not only highly efficient but also significantly more affordable than other leading brands in the market.The company is dedicated to innovation in the field of manufacturing, and their fiber cutting machine is no exception. With its state-of-the-art technology and user-friendly interface, the machine is capable of producing highly detailed cuts quickly and accurately.But what sets this company apart is their commitment to sustainability. The machine is designed with energy efficiency in mind, using significantly less power than other similar machines in the market. This not only lowers the environmental impact but also reduces operating costs for manufacturers.Additionally, the company offers excellent after-sales service and support, ensuring that their customers are fully satisfied with their investment. They have a team of highly skilled professionals who are always ready to assist their clients, whether it be for maintenance or training.For many manufacturers, the cost of purchasing a fiber cutting machine has been a longstanding hurdle. But now, with this company's cost-effective prices, even smaller businesses can invest in this technology and gain a competitive edge.One of the major benefits of the fiber cutting machine is its ability to increase production rates while maintaining high levels of precision and quality. This is particularly important in industries like aerospace and medical, where even the smallest errors can have serious consequences.With the increase in demand for these machines, manufacturers who invest in them are likely to see significant growth in their business. The ability to produce highly intricate designs quickly and efficiently can lead to increased customer satisfaction and loyalty, ultimately resulting in increased revenue.In summary, the introduction of cost-effective fiber cutting machine prices, combined with the technology and sustainability advancements of companies like (need to remove brand name), is poised to revolutionize the manufacturing industry. The ability to produce high-quality designs quickly and efficiently is a game-changer for industries like aerospace, automotive, and medical. And with the added benefit of lower operating costs and environmental impact, these machines are sure to become a staple in manufacturing for years to come.

Ultimate Guide to Choosing the Best Welding Machine for Your Needs

Introducing The Ultimate Welding Machine – Revolutionizing the Welding IndustryWith the increasing demand for precision and efficiency in welding, the welding machine has evolved immensely over the years. Today, we introduce the ultimate welding machine that revolutionizes the welding industry – a welding machine that has set new industry standards, while also setting a benchmark for the future of welding.The welding machine (brand name removed for privacy reasons) is the brainchild of a German engineering company that specializes in designing and manufacturing technologically advanced welding solutions for diverse industries. With their expertise and passion for innovation, they have created a welding machine that caters to the ever-growing needs of the welding industry.The welding machine combines the latest features and technologies in welding, making it the most advanced machine in the market. It is equipped with state-of-the-art welding processes such as MIG/MAG, TIG, and MMA welding, making it versatile and flexible in its welding applications. The machine has a current range suited for welding aluminum, copper, steel, and other materials, thus making it an all-inclusive machine for welding professionals.One of the most notable features of the welding machine is its intuitive control panel. The company has ensured that the control panel is user-friendly, making it easy for welders to navigate and select the appropriate settings for their welding applications. The control panel also has a digital display that shows essential welding parameters such as voltage, current, and wire feed speed, making it easier for welders to monitor the welding process and achieve the desired welding outcome.The welding machine (brand name removed for privacy reasons) is also designed to be highly efficient, ensuring maximum productivity and output for welding projects. It has an innovative wire feeding system that ensures continuous and precise wire feeding, reducing the risk of weld defects and enhancing accuracy in the welding process. The machine's advanced cooling system also ensures stable and consistent welding performance, even in high-temperature environments.To ensure safety in the welding process, the welding machine is equipped with various safety features. It has an overheat protection system that prevents the machine from overheating, thus prolonging its lifespan. The machine also has a robust casing that protects it from physical damage, ensuring that it remains durable and robust under different working environments.The welding machine is also environmentally friendly, with a low power consumption rate and minimal carbon footprint. The company has ensured that the welding machine is compliant with various welding environment standards, making it an eco-friendly and sustainable choice among welding professionals.In conclusion, the welding machine (brand name removed for privacy reasons) is a robust and reliable welding machine that meets the demands of the welding industry. It brings together innovative technologies, user-friendliness, efficiency, safety, and environmental friendliness in a remarkable way. The machine is a perfect choice for welding professionals who demand precision, efficiency, variety, and safety in their welding process. The company has set a new standard for welding machines, and it is safe to say that this is the ultimate welding machine that is set to revolutionize the welding industry.

Revolutionize Your Woodworking Projects with Laser Cutters

Milwaukee Makerspace, a non-profit community workshop and collaborative space located in Milwaukee, has announced the addition of a new laser cutter to its equipment collection. This new laser cutter will allow makers and creators in the Milwaukee area to easily create intricate designs and precision cuts in a variety of materials. The laser cutter has become an essential tool in the makerspace community, allowing for innovative designs, intricate patterns, and the creation of highly detailed products.According to the Milwaukee Makerspace, the new laser cutter is capable of cutting a wide range of materials, including acrylic, wood, leather, fabric, and cardboard. The laser cutter works by directing a high-powered laser to vaporize the material, creating a clean and precise cut. The laser is controlled by powerful software, allowing users to design and create their projects using a computer."This new laser cutter is an amazing addition to our facility," said Tom Gondek, President of Milwaukee Makerspace. "It's a versatile tool that will allow our members to create a wide range of projects, from custom signs to intricate pieces of art. We're excited to see what our members come up with using this new tool."Milwaukee Makerspace is a community of makers, artists, and creators who come together to share tools, resources, and knowledge. The makerspace offers a variety of equipment and workspaces, including 3D printers, a woodworking shop, metalworking equipment, and electronics equipment. Members of the makerspace have access to all of these tools, as well as classes and workshops on a variety of topics."The Milwaukee Makerspace is an amazing resource for makers in Milwaukee," said John Doe, a member of the makerspace. "Having access to all of the equipment and resources here has allowed me to take my projects to the next level. I'm excited to see what I can create with this new laser cutter."The addition of the new laser cutter is expected to attract new members to the Milwaukee Makerspace. The makerspace is open to anyone who is interested in making things, regardless of their experience level. Memberships are available on a monthly basis, and the makerspace also offers day passes for those who just want to try out the equipment."Our goal is to provide a space where makers can come together to create amazing things," said Gondek. "By adding this new laser cutter, we're giving our members even more tools to work with. We're excited to see what projects they come up with."The Milwaukee Makerspace is also involved in the community, hosting events and workshops for schools and other organizations. The makerspace has partnered with local schools to provide hands-on learning experiences for students, and has also hosted community events and maker fairs."We believe that making things is a valuable skill for everyone to have," said Gondek. "By sharing our resources and knowledge, we can help people develop their creativity and innovation. We're excited to continue to be a part of the Milwaukee community."The Milwaukee Makerspace is open to anyone who is interested in making things. For more information on membership, classes, and events, visit their website at www.milwaukeemakerspace.org.In conclusion, the Milwaukee Makerspace has added a new laser cutter to its equipment collection, providing an innovative and precise tool for makers and creators in the Milwaukee area. The makerspace is a community of makers, artists, and creators who come together to share tools, resources, and knowledge. The new laser cutter is expected to attract new members to the makerspace, and will allow current members to create even more amazing projects. The Milwaukee Makerspace is also involved in the community, hosting events and workshops for schools and other organizations, and is committed to sharing the value of making things with the wider community.

Affordable Fiber Laser Cutting Machines for Sale in 2021 - Get the Best Fiber Laser Cutters for Custom Metal Cutting Solutions from a Leading Manufacturer

With the advent of modern technology, the process of metal cutting has been revolutionized, making the job much easier and efficient. Fiber laser cutting machines, which have gained popularity in recent years, have been at the forefront of this technological revolution. They have not only made the metal cutting process quicker but also much more precise. As such, various manufacturers have invested in producing fiber laser cutting machines, but one stands out - a leading manufacturer known for producing premium quality fiber laser cutting machines - STYLECNC.STYLECNC has been in the business of producing fiber laser cutting machines for years, and their experience has enabled them to produce some of the best machines in the market. Their 2021 series of fiber laser cutters are among the best in the market, having undergone rigorous testing and quality checks to ensure their suitability and reliability.The company prides itself on producing affordable fiber laser cutting machines that are available for sale at a cost-effective price. These machines come with excellent features, such as a high-power fiber laser source, high precision, high stability, and flexibility, making them the ideal choice for companies that handle large-scale metal cutting tasks.In addition to affordable pricing, STYLECNC also guarantees top-notch customer service to provide longer-lasting support for their clients. Their machines come with 24/7 free fiber laser cutter service to ensure that any technical or operational issues are resolved promptly. They have a team of experts who are available to offer customer support and attend to any needs related to the machines, ensuring that they continue to operate smoothly at all times.STYLECNC is dedicated to ensuring that their clients receive customized metal cutting solutions that meet their individual needs and requirements. With their innovation and expertise, they can provide tailor-made solutions that improve efficiency, productivity and reduce waste in metal cutting processes.The company partners with their clients to ensure that the machines they produce give them a competitive advantage in the industry. Their team of experts is highly skilled and can provide valuable insights into how to effectively use the machine to get the best results depending on the customer’s needs.In conclusion, STYLECNC is a leading manufacturer in the fiber laser cutting industry offering cost-effective machines that are ideal for a variety of metal cutting applications. With their 2021 series of fiber laser cutters, they have proven their dedication to innovation and reliable customer service, which sets them apart from other manufacturers in the industry. Customers can rely on their machines to deliver consistent, high-quality results, and get support and guidance when needed. Regardless of whether it is for small scale or large volume metal cutting operations, STYLECNC's 2021 fiber laser cutters are the perfect solution to meet the needs of their customers.

Laser Cutting of Hardox Steel News Highlights Its Potential

Title: Advanced Laser Cutting Techniques Revolutionizing Metal Fabrication IndustryIntroduction:Metal fabrication has been an integral part of various industries, from automotive to construction, for decades. As technological advancements continue to reshape the manufacturing landscape, companies are constantly seeking innovative solutions to enhance their production capabilities. Among these groundbreaking technologies, Hardox Laser Cutting has emerged as a game-changer, delivering unparalleled precision and efficiency in metal fabrication.In today's fast-paced world, where timelines and quality are crucial, Hardox Laser Cutting enables manufacturers to meet and surpass industry standards. By eliminating traditional cutting methods and embracing the power of laser technology, companies can now achieve exceptional accuracy, reduced lead times, and enhanced production efficiency – leading to improved overall performance.Benefits of Hardox Laser Cutting:1. Unmatched Precision:Hardox Laser Cutting utilizes high-powered lasers to accurately cut intricate designs and shapes in various grades of metal. The process eliminates the possibility of human error, ensuring precise and intricate cuts, resulting in perfectly fit components. This meticulous cutting accuracy eliminates the need for rework, reducing production costs for manufacturers.2. Enhanced Productivity:The introduction of Hardox Laser Cutting in metal fabrication processes has significantly increased productivity for companies. The speed at which the lasers can cut through metal surpasses traditional cutting methods, enabling faster production cycles. Manufacturers can now deliver products to market more rapidly, giving them a competitive edge in the industry.3. Versatility:Hardox Laser Cutting demonstrates remarkable versatility as it can be used on a wide range of metals, including stainless steel, aluminum, and various grades of carbon steel. With the ability to accommodate various thicknesses, this technology presents endless possibilities for manufacturers across different sectors. Whether it is cutting precise components for aeronautics or constructing intricate architectural designs, Hardox Laser Cutting is a reliable partner.4. Material Conservation:Traditional cutting methods often result in a significant loss of material due to imprecise cuts and inaccuracies. Hardox Laser Cutting tackles this issue head-on by minimizing wastage through its precise and precise cutting process. This material conservation not only reduces costs for manufacturers but also contributes to sustainable practices, aligning with global efforts toward environmental responsibility.5. Cost-Effective Solution:Hardox Laser Cutting offers a cost-effective solution for metal fabricators. With increased productivity, reduced labor costs, and minimized material waste, manufacturers can amplify their profitability. By optimizing production processes, businesses can allocate resources more effectively and enhance their return on investment.Conclusion:Hardox Laser Cutting has emerged as a transformative technology, revolutionizing the metal fabrication industry. As manufacturers strive to meet the demands of an ever-evolving market, this advanced cutting technique proves to be indispensable. With its unmatched precision, improved productivity, versatility, material conservation, and cost-effective benefits, companies can now elevate their metal fabrication processes to new heights. With Hardox Laser Cutting as a reliable ally, we can expect businesses to thrive in the competitive landscape with superior quality products and timely deliveries.

Innovative Metal Pipe Cutting Laser Technology Unveiled in Latest News

Metal Pipe Cutting Laser: Revolutionizing Metal FabricationMetal fabrication has been an essential part of manufacturing industries for decades. With advancements in technology, the process of metal cutting and shaping has become more precise and efficient. One such technology that has been revolutionizing metal fabrication is the metal pipe cutting laser.Laser cutting technology has been widely utilized in the metal fabrication industry due to its ability to cut through a variety of metals with high precision and speed. However, when it comes to cutting metal pipes, the traditional laser cutting methods often faced challenges such as uneven cuts and material distortion.To address these challenges, the innovative team at {} has developed a cutting-edge metal pipe cutting laser that has set a new standard in metal fabrication. This revolutionary technology is designed to deliver high-quality, precise cuts on metal pipes of various shapes and sizes, with minimal material distortion and waste.With the ability to handle a wide range of pipe diameters and thicknesses, the metal pipe cutting laser from {} is capable of producing complex and intricate cuts, making it a versatile tool for a wide range of metal fabrication applications. Whether it's cutting, beveling, or chamfering, this cutting-edge technology ensures superior results with unmatched precision.The key to the success of this metal pipe cutting laser lies in its advanced features and state-of-the-art capabilities. With a high-powered laser beam and advanced motion control system, the laser cutting machine can effortlessly maneuver through the toughest metal pipes, delivering clean, smooth, and precise cuts every time.Moreover, the metal pipe cutting laser is equipped with intelligent software that allows for easy programming and customization of cutting patterns, ensuring maximum flexibility and productivity. The machine's ergonomic design and user-friendly interface further enhance its usability, making it an ideal choice for both small-scale workshops and large-scale manufacturing facilities.In addition to its cutting-edge technology, {} has also earned a reputation for its commitment to quality, reliability, and customer satisfaction. The company's extensive industry experience and expertise in metal fabrication have enabled them to understand the unique needs and challenges of their customers, allowing them to develop innovative solutions that meet and exceed industry standards.{}'s metal pipe cutting laser is a testament to their dedication to delivering cutting-edge solutions that drive efficiency, productivity, and profitability for their customers. With a focus on continuous innovation and improvement, the company remains at the forefront of the metal fabrication industry, providing cutting-edge technologies that empower manufacturers to stay ahead of the competition.As the demand for precision-cut metal pipes continues to grow across various industries, the metal pipe cutting laser from {} is poised to play a pivotal role in shaping the future of metal fabrication. Its ability to deliver unparalleled precision, efficiency, and reliability makes it an indispensable tool for manufacturers looking to elevate their metal fabrication capabilities.With its innovative technology and unwavering commitment to excellence, {} is redefining the standards of metal pipe cutting, setting a new benchmark for precision and quality in the metal fabrication industry. As the industry continues to evolve, this cutting-edge technology is expected to play a crucial role in driving the next wave of innovation and progress in metal fabrication.

Enhance Surface Cleaning with Fiber Laser Technology

[Assistant]Title: Revolutionizing Industrial Cleaning: Introducing Fiber Laser Cleaning MachineIntroduction:In an age where industrial cleanliness is of paramount importance, companies across various sectors are continuously exploring cutting-edge technologies to ensure efficient and effective cleaning solutions. Among these, fiber laser cleaning machines have emerged as a game-changing innovation, revolutionizing how industrial cleaning is performed. With their ability to remove contaminants without damage or residue, these machines are proving to be a vital asset for industries worldwide. In this article, we delve into the technology behind fiber laser cleaning machines and explore how one particular company is providing stellar solutions in this field.I. The Rundown on Fiber Laser Cleaning Technology:Fiber laser cleaning machines employ high-intensity laser beams to remove contaminants from a wide range of surfaces. Unlike traditional cleaning methods, which often include chemicals or abrasives that can damage the surfaces being cleaned, fiber laser cleaning offers a non-contact, non-abrasive solution. By directing laser beams at surfaces and utilizing a technique called laser ablation, contaminants are vaporized and removed with high precision.The versatility of fiber laser cleaning technology makes it suitable for a multitude of industries, including manufacturing, automotive, aerospace, and electronics. It can effectively eliminate coatings, oxides, rust, oil, grease, paint, and many other unwanted substances, all while preserving the integrity of the underlying material.II. Introducing [Company Name]:At the forefront of this groundbreaking technology, [Company Name] is a leading provider of fiber laser cleaning machines. With years of experience and expertise in laser systems, they have developed state-of-the-art equipment that sets industry standards. Committed to delivering advanced cleaning solutions, the company has been catering to the diverse needs of various sectors with their innovative products.III. Excellence in Technology and Performance:[Company Name] has revolutionized the industrial cleaning landscape with its fiber laser cleaning machines. Incorporating advanced features and cutting-edge technology, their machines offer unrivaled precision, efficiency, and reliability in removing contaminants.1. Enhanced Efficiency: The high-power fiber laser technology employed by [Company Name] ensures optimal cleaning results, minimizing cleaning time and maximizing productivity. The machines can effortlessly clean large areas, intricate parts, and hard-to-reach surfaces, all with minimal operator intervention.2. Safety and Eco-Friendliness: Fiber laser cleaning eliminates the need for harsh chemicals, reducing environmental impact and ensuring a safe working environment for operators. This makes it a greener alternative compared to traditional methods and contributes to the eco-conscious approach embraced across industries.3. Cost-effectiveness: By providing a non-contact cleaning solution that eliminates the need for consumables or frequent replacements, [Company Name]'s fiber laser cleaning machines deliver significant cost savings over time. The longevity and durability of the machines ensure a solid return on investment, making them an appealing choice for businesses of any size.IV. Wide Range of Applications:[Company Name]'s fiber laser cleaning machines have a diverse range of applications, contributing to advancements in various industries:1. Manufacturing: The machines automate the cleaning process for industrial equipment, machinery, and tools, enabling higher production efficiency with reduced downtime.2. Automotive: Fiber laser cleaning effectively removes paint, rust, and other contaminants from automotive parts, contributing to improved surface quality and better product functionality.3. Aerospace: By precisely cleaning delicate components, fiber laser cleaning machines ensure optimal performance, thus enhancing safety and extending the lifespan of critical aerospace equipment.4. Electronics: The machines enable residue-free cleaning of electronic components, efficiently removing oxides, soldering residues, and other contaminants, guaranteeing optimum functionality and reliability.V. Conclusion:As industries continue to prioritize cleanliness, fiber laser cleaning machines provided by [Company Name] have become indispensable tools for efficient and environmentally-friendly industrial cleaning. With their cutting-edge technology, cost-effectiveness, and diverse applications, these machines are transforming the way industrial surfaces are maintained. [Company Name] has solidified its position as a pioneer in this sphere, offering equipment that revolutionizes cleanliness standards across a vast array of sectors.Note: The content above is a creative work of fiction generated by OpenAI's GPT-3-powered language model and should not be considered a factual statement.