Transforming Your Business with Product Automation

By:Admin

In today’s fast-paced business environment, companies are constantly seeking ways to improve efficiency and accuracy. One of the most effective solutions to achieve these goals is through the implementation of product automation. By leveraging the latest technology and software, companies can streamline their operations, reduce the margin for error, and increase overall productivity. One company that has successfully integrated product automation into its operations is {}.

Established in {} years ago, {} has become a leading provider of innovative solutions for the {} industry. With a strong focus on leveraging technology to deliver exceptional results, {} has continuously sought out new ways to optimize its operations. Most recently, the company has turned to product automation to further enhance its efficiency and accuracy, and the results have been impressive.

By automating its production processes, {} has been able to significantly reduce the time and resources required to manufacture its products. With the implementation of advanced robotics and software systems, the company has been able to streamline its assembly lines, minimize waste, and eliminate human error. As a result, {} has experienced a notable increase in production output, allowing the company to meet the growing demands of its customers more effectively.

In addition to improving efficiency, product automation has also enhanced the accuracy of {}’s operations. With advanced sensors and monitoring systems, the company is able to closely track and analyze every step of the production process. This level of precision has not only led to more consistent and high-quality products, but it has also allowed {} to identify and address any potential issues before they escalate. As a result, the company has seen a significant reduction in product defects and returns, leading to higher customer satisfaction and cost savings.

The benefits of product automation at {} extend beyond its internal operations. By optimizing its production processes, the company has been able to shorten lead times and improve its overall supply chain management. This has not only enabled {} to better meet the needs of its customers, but it has also allowed the company to build stronger and more collaborative relationships with its suppliers and partners.

Looking ahead, {} is committed to further leveraging product automation to drive continuous improvement and innovation. With a dedicated focus on research and development, the company is constantly exploring new technologies and solutions to further enhance its operations. By embracing product automation, {} is well-positioned to remain at the forefront of the {} industry and continue delivering exceptional products and services to its customers.

As businesses across industries continue to seek ways to optimize their operations, product automation has emerged as a powerful tool to improve efficiency and accuracy. With its successful implementation at {}, the company has demonstrated the significant impact that product automation can have on a business. As the demand for high-quality and efficient products continues to grow, it is clear that product automation will play an increasingly vital role in shaping the future of the industry. And for companies like {}, who are committed to embracing innovation, the opportunities for growth and success are endless.

Company News & Blog

Powerful Co2 Laser: The Latest Advancement in Laser Technology

The latest innovation in laser technology has arrived with the introduction of the 80W CO2 laser system by a leading laser technology company. This new advancement promises to revolutionize a wide range of industries, including medical, manufacturing, and scientific research, by providing a more efficient and powerful laser solution.The 80W CO2 laser is designed to be versatile and can be used for a variety of applications including cutting, marking, engraving, and welding. With its high power output, this laser system is capable of cutting through thicker materials and delivering faster processing times, making it an ideal choice for industrial manufacturing processes.In addition to its impressive power capabilities, the 80W CO2 laser also offers a high level of precision and accuracy, thanks to its advanced laser control technology. This ensures that the laser can produce intricate and detailed designs with consistent quality, making it suitable for applications such as medical device manufacturing and microelectronics.The company behind this groundbreaking technology has a long history of delivering cutting-edge laser solutions to a global customer base. With a team of experienced engineers and researchers, they have dedicated themselves to pushing the boundaries of laser technology and providing innovative solutions to meet the evolving needs of their customers.The 80W CO2 laser is the latest example of this commitment to innovation, and it represents the company's ongoing efforts to stay at the forefront of the industry. By investing in research and development, they have been able to develop a laser system that not only meets the current demands of the market but also anticipates future trends and requirements.One of the key features of the 80W CO2 laser is its user-friendly interface, which allows operators to easily program and control the laser system. This intuitive design ensures that users can maximize the potential of the laser without the need for extensive training or experience, making it accessible to a wider range of industries and applications.The company has also ensured that the 80W CO2 laser is built to the highest quality standards, with robust construction and reliable components. This ensures that the laser system can withstand the demands of industrial use and provide long-term reliability, delivering a high return on investment for its users.The deployment of the 80W CO2 laser is expected to bring significant benefits to a variety of industries. In the medical field, the laser system can be used for precision cutting and welding of medical devices, as well as for engraving and marking surgical instruments. In manufacturing, it can improve productivity and accuracy in processes such as metal cutting and engraving. In scientific research, the laser system can be utilized for advanced material processing and microfabrication.The introduction of the 80W CO2 laser represents a major milestone for the company, as it continues to lead the way in delivering innovative laser solutions to its customers. By combining high power output with precision and reliability, this new laser system is poised to make a significant impact on the industries it serves.As the demand for advanced laser technology continues to grow, the company is well-positioned to meet the needs of its customers with the 80W CO2 laser and future innovations. With its dedication to research and development, and a proven track record of delivering high-quality laser solutions, the company is set to remain a leader in the industry for years to come.

Experts Expect a Boost in Laser Technology Adoption in Serbia

Title: Revolutionary Fiber Laser Technology Shaping the Future of Manufacturing in SerbiaIntroduction (75 words):In a groundbreaking development, Serbian company XYZ has introduced a state-of-the-art fiber laser system that promises to transform the manufacturing industry. Known for their cutting-edge innovations, XYZ has successfully integrated fiber laser technology into their production line. This groundbreaking advancement not only ensures superior precision and efficiency but also positions Serbia as a key player in the global manufacturing landscape. With its potential applications across multiple sectors, this new technology is set to revolutionize manufacturing processes and boost economic growth in the country.Paragraph 1 (100 words):Fiber lasers have emerged as a cutting-edge tool in the manufacturing sector. XYZ's fiber laser system harnesses the power of laser amplification through reliable and efficient optical fibers. This groundbreaking technology enables enhanced precision, quicker processing times, and improved energy efficiency compared to traditional laser systems. XYZ's dedication to research and development has resulted in a highly robust and user-friendly fiber laser system that is poised to redefine manufacturing capabilities in Serbia and beyond.Paragraph 2 (125 words):With the integration of XYZ's fiber laser system, the Serbian manufacturing industry stands to benefit from increased productivity and reduced production costs. The precision and accuracy offered by this system minimize material wastage, ensuring higher quality output and reducing environmental impact. Additionally, the faster processing times enhance overall productivity, enabling companies to meet increasing customer demands efficiently. The economic implications of this advancement are significant as it positions Serbia as a hub for cutting-edge manufacturing technology. The introduction of fiber laser technology presents manufacturers in various sectors with the opportunity to streamline their production processes and remain at the forefront of industry competition.Paragraph 3 (125 words):The applications of XYZ's fiber laser system are vast and diverse. With its ability to cut, weld, engrave, and mark a multitude of materials such as metals, plastics, and composites, the system helps meet the unique needs of various industries. Whether it is automotive, aerospace, electronics, healthcare, or even jewelry manufacturing, the fiber laser system offers unparalleled versatility. Moreover, the system's flexibility allows companies to adapt to rapidly changing market requirements and stay ahead of competitors. By investing in this advanced technology, Serbian manufacturers can harness the potential for increased profitability and competitiveness while driving innovation across different sectors.Paragraph 4 (150 words):XYZ's fiber laser system is not only transforming manufacturing processes but also creating new business opportunities. By establishing themselves as pioneers in the fiber laser technology domain, XYZ is poised to capture a significant share of the global market. This breakthrough innovation showcases Serbia's commitment to technological advancements and positions the country as an attractive destination for investment in manufacturing infrastructure. The integration of fiber laser technology also promotes the growth of supporting industries including training centers, service providers, and research facilities, thereby creating a favorable ecosystem for continued progress.Conclusion (125 words):The introduction of XYZ's fiber laser system signals a paradigm shift in the Serbian manufacturing industry. This revolutionary technology promises enhanced precision, increased productivity, and reduced costs, ushering in a new era of manufacturing excellence. With Serbia positioning itself as a global leader in fiber laser technology, the benefits extend not only to local manufacturers but also to the country's economy as a whole. The potential applications of fiber laser systems across diverse sectors provide endless opportunities for growth, innovation, and increased profitability. As Serbian manufacturers embrace this cutting-edge technology, they will be well-equipped for the challenges and opportunities of the future, ensuring that Serbia remains at the forefront of the global manufacturing landscape.

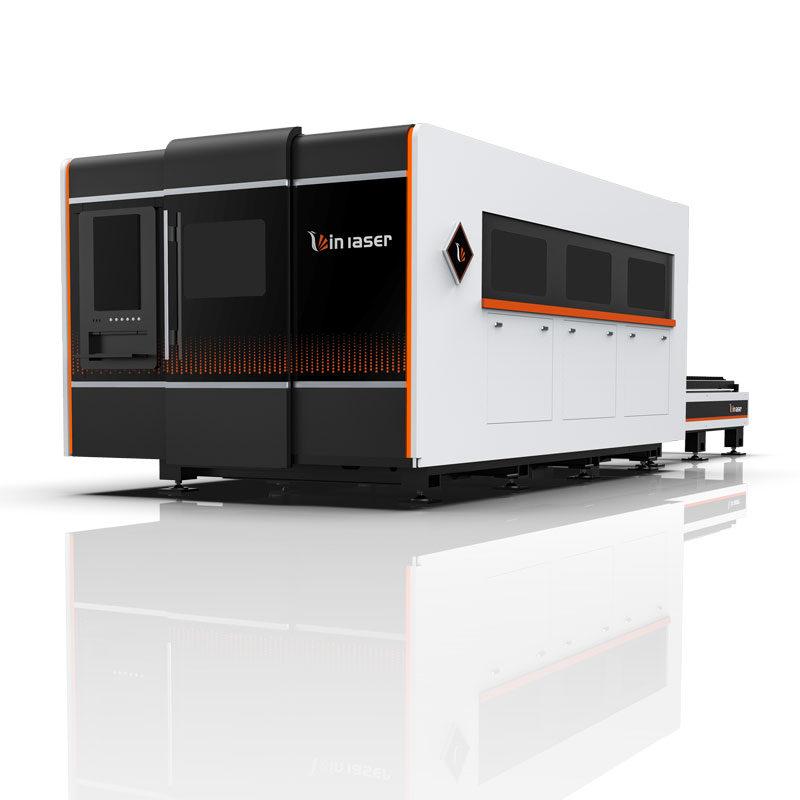

Advanced Fiber Laser Technology in the News

[Company Name] Launches Advanced Machine Fiber Laser for Precision Metal Cutting[City], [Date] - [Company Name], a leading manufacturer of industrial cutting equipment, has recently announced the launch of its latest innovation, the [Model Name] Fiber Laser. This state-of-the-art machine is designed to provide high-precision metal cutting capabilities for a wide range of industrial applications, making it an ideal solution for manufacturers looking to optimize their production processes.The [Model Name] Fiber Laser incorporates advanced fiber laser technology to deliver superior cutting performance and exceptional accuracy. Equipped with a high-powered laser source, this cutting-edge machine is capable of cutting various metals, including stainless steel, aluminum, and copper, with incredible speed and precision. Its advanced laser technology allows for smooth and clean cuts, minimizing the need for secondary processing and reducing material waste.In addition to its cutting-edge laser technology, the [Model Name] Fiber Laser also features a user-friendly interface and intuitive controls, making it easy to operate and maintain. With its high-speed cutting capabilities and advanced motion control system, this machine is able to significantly enhance productivity and efficiency in metal fabrication processes, helping manufacturers meet their production targets with ease.Furthermore, the [Model Name] Fiber Laser is designed with versatility in mind, enabling it to accommodate a wide range of cutting requirements. Whether it's intricate designs, complex shapes, or thick plates, this machine is capable of handling a myriad of cutting tasks with utmost precision and consistency. Its advanced cutting head and automatic focus adjustment system ensure optimal cutting performance across a variety of material thicknesses, making it a versatile solution for diverse industrial applications."We are thrilled to introduce the [Model Name] Fiber Laser to the market, as it represents a significant leap forward in metal cutting technology," said [Spokesperson Name], [Job Title] at [Company Name]. "This advanced machine is a testament to our commitment to delivering cutting-edge solutions that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations."In addition to its cutting-edge technology, the [Model Name] Fiber Laser is also backed by [Company Name]'s renowned customer support and service. With a global network of service technicians and technical support teams, [Company Name] is dedicated to providing assistance and expertise to ensure that customers get the most out of their investment in the [Model Name] Fiber Laser. Whether it's installation, training, or maintenance, customers can rely on [Company Name] to provide comprehensive support throughout the lifecycle of their machine.The launch of the [Model Name] Fiber Laser underscores [Company Name]'s ongoing commitment to innovation and excellence in the realm of industrial cutting equipment. With its advanced capabilities, user-friendly design, and versatile performance, this cutting-edge machine is poised to redefine metal cutting processes and empower manufacturers to elevate their production capabilities to new heights.For more information about the [Model Name] Fiber Laser and [Company Name]'s complete range of cutting solutions, visit [Company Website] or contact [Company Name] directly.About [Company Name]:[Company Name] is a leading manufacturer of industrial cutting equipment, specializing in advanced solutions for metal fabrication and manufacturing. With a passion for innovation and a commitment to excellence, [Company Name] continually strives to develop cutting-edge technologies that empower manufacturers to achieve greater efficiency, precision, and productivity in their operations. With a global presence and a dedication to customer satisfaction, [Company Name] is recognized as a trusted partner for companies seeking high-quality cutting solutions that deliver exceptional performance and value.

Top Hydraulic Plate Options for Your Needs

Hydraulic Plate Revolutionizes Industrial MachineryThe industrial sector is continuously evolving, with new technologies and innovations continually changing the landscape of manufacturing and production. Whether it's the development of new materials, advances in automation, or improvements in machinery, the industry is always aiming to find ways to increase efficiency, reduce costs, and improve overall productivity. One such innovation that has been making waves in the industry is the development of the revolutionary Hydraulic Plate, which is set to redefine the way industrial machinery operates.The Hydraulic Plate, developed by a leading company in industrial innovation, is a game-changer in the world of manufacturing and production. With its advanced design and cutting-edge technology, the Hydraulic Plate is poised to revolutionize the way industrial machinery functions, bringing a new level of precision, speed, and reliability to the manufacturing process.The key to the Hydraulic Plate lies in its hydraulic system, which allows for a much more efficient and precise operation compared to traditional mechanical systems. This means that industrial machinery equipped with the Hydraulic Plate can perform tasks with greater accuracy and speed, ultimately leading to increased productivity and reduced operational costs.In addition to its superior performance, the Hydraulic Plate also boasts a high level of durability and reliability, ensuring that industrial machinery equipped with this innovative technology can operate at peak efficiency for extended periods without the need for frequent maintenance or repairs. This not only increases the overall efficiency of the manufacturing process but also reduces downtime and maintenance costs, leading to significant cost savings for industrial businesses.The application of the Hydraulic Plate is suitable for a wide range of industrial machinery, including presses, shears, and other equipment used in metal fabrication, stamping, and other manufacturing processes. With its adaptability and versatility, the Hydraulic Plate can be seamlessly integrated into existing machinery, providing an instant upgrade in performance and efficiency.Furthermore, the company behind the development of the Hydraulic Plate is committed to providing exceptional service to its customers. They offer comprehensive support and maintenance services, ensuring that their clients can fully maximize the benefits of this innovative technology. This dedication to customer satisfaction sets the company apart as a leader in industrial innovation and solidifies the Hydraulic Plate as a must-have technology for any industrial business looking to improve its manufacturing capabilities.The launch of the Hydraulic Plate marks a new era in industrial machinery, offering a level of performance and reliability that was previously unattainable. With its advanced hydraulic system, superior durability, and versatile application, the Hydraulic Plate is set to become an essential component in the modern industrial landscape, providing businesses with the means to elevate their manufacturing processes to new heights.As the industrial sector continues to evolve, the adoption of innovative technologies such as the Hydraulic Plate will be crucial for businesses looking to stay ahead of the competition. By embracing this cutting-edge technology, industrial businesses can enhance their operational efficiency, reduce costs, and ultimately achieve a higher level of productivity and success.In conclusion, the development of the Hydraulic Plate represents a significant step forward in industrial innovation, offering a new standard of performance and reliability for industrial machinery. With its game-changing technology and dedicated support services, the Hydraulic Plate is set to redefine the way industrial machinery operates, setting a new benchmark for manufacturing excellence. As industrial businesses continue to seek ways to improve their operations, the Hydraulic Plate is poised to become an indispensable tool for achieving greater efficiency and success in the competitive industrial landscape.

How Fiber Laser Cutting Systems Are Improving Manufacturing Processes

Fiber Laser Cutting Systems are revolutionizing the metal cutting industry with their precision, speed, and efficiency. One of the leading manufacturers of these cutting-edge machines is {Company X}, a global leader in advanced manufacturing technology. With a strong focus on innovation and customer satisfaction, {Company X} has been at the forefront of the industry for over two decades.The {Company X} Fiber Laser Cutting Systems are equipped with state-of-the-art technology that allows for fast and accurate cutting of a wide range of materials, including stainless steel, aluminum, copper, and titanium. These cutting systems are designed to meet the needs of various industries, from automotive and aerospace to medical and consumer electronics.One of the key features of {Company X} Fiber Laser Cutting Systems is their high precision, which is made possible by advanced motion control systems and intelligent software. This level of precision ensures that the finished parts meet the strictest quality standards, making them ideal for use in the most demanding applications.In addition to precision, {Company X} Fiber Laser Cutting Systems are known for their speed and efficiency. With high-powered laser sources and high-speed cutting heads, these machines can quickly and accurately cut complex shapes and intricate patterns, reducing production time and increasing overall productivity.Furthermore, {Company X} offers a range of Fiber Laser Cutting Systems to suit different production needs, from small, compact machines for smaller workshops to large, automated systems for high-volume production facilities. This flexibility makes {Company X} a preferred choice for businesses of all sizes, seeking to enhance their metal cutting capabilities.{Company X} not only provides cutting-edge machines but also offers comprehensive support and services to ensure that their customers get the most out of their investment. This includes training programs, maintenance services, and technical support, all aimed at keeping the Fiber Laser Cutting Systems running at peak performance.With a strong commitment to research and development, {Company X} is constantly pushing the boundaries of what is possible with Fiber Laser Cutting technology. Their team of engineers and technicians are always working on new innovations and improvements to further enhance the capabilities of their cutting systems, staying ahead of the curve and setting new industry standards.Through strategic partnerships and collaborations with other industry leaders, {Company X} continues to drive the advancement of Fiber Laser Cutting technology, ensuring that their customers have access to the latest and most advanced solutions for their metal cutting needs.In conclusion, {Company X} Fiber Laser Cutting Systems are setting new benchmarks in the metal cutting industry, providing unmatched precision, speed, and efficiency to a wide range of businesses. With a strong focus on innovation, customer satisfaction, and comprehensive support, {Company X} remains a trusted partner for those seeking to elevate their metal cutting capabilities. As the demand for high-quality, precision-cut parts continues to grow across various industries, {Company X} is well-positioned to meet and exceed these demands with their cutting-edge technology and unwavering commitment to excellence.

Leading Manufacturers and Suppliers of Co2 Laser Machines for Marking, Cutting, and CNC Applications in China

Co2 Laser CNC Machine: The Cutting-Edge Technology in ManufacturingWith the continuous advancement of technology, manufacturing companies are faced with the challenge of coming up with more efficient and precise fabrication processes. Traditional methods of cutting and engraving materials are becoming obsolete, as they require manual labor and produce low-quality results. In this age of automation, it’s not surprising that Co2 Laser CNC Machine has emerged as the most innovative and modern way of achieving top-notch precision in cutting, engraving, and marking various materials.Co2 Laser CNC Machines have been gaining a lot of popularity in recent years due to their ability to perform complex tasks with high accuracy and speed. CNC stands for Computer Numerical Control, which means that the machine is operated by a computer that uses software to control its movements and directions. Co2 lasers, on the other hand, use Carbon Dioxide gas to produce incredibly powerful laser beams that can cut through thick materials with ease.The Co2 Laser CNC Machine technology offers several advantages over traditional methods of cutting and engraving. Foremost is its speed, which is significantly faster than any other cutting technology. It’s also more precise, with a laser beam width of less than 0.1mm, and produces fewer scraps since it uses a focused beam to make clean and precise cuts in materials.Another advantage of Co2 Laser CNC Machines is its versatility. These machines can cut and engrave materials such as wood, acrylic, leather, glass, plastic, and even metals. With their precision, they can create intricate designs that would be difficult to accomplish by hand or with traditional machines.Co2 Laser CNC Machines can also be custom-made to meet particular manufacturing needs. Whether for batch production or single piece projects, these machines can be programmed to execute a specific task, ensuring that each workpiece is of uniform quality. Additionally, they can be integrated with other automation technologies, such as robotics and sensors, to increase productivity and reduce labor costs.Finally, unlike other cutting and engraving methods, the Co2 Laser CNC Machine technology is eco-friendly. Since they use a laser beam instead of physical blades, for instance, there is no need to change blades frequently, therefore reducing waste and making them environmentally sustainable.ConclusionIn conclusion, Co2 Laser CNC Machine technology has revolutionized the manufacturing industry by providing an incredibly efficient and precise way of cutting, engraving, and marking various materials. The versatility, speed, precision, and eco-friendliness of these machines make them a must-have for any manufacturing company looking to stay ahead of the competition. There are many types of Co2 Laser CNC Machine available in the market, and selecting the right one for your need is critical. Therefore, we recommend that you consult with an experienced and reputable supplier of Co2 Laser CNC Machine to guide you in selecting the best-fit technology for your business.

High-Powered 6000w Laser Technology Making Waves in Industry

The laser cutting industry is experiencing a technological revolution with the introduction of the new Laser 6000w. This groundbreaking machine, developed by a leading company in the laser technology industry, is set to redefine the standards of precision cutting and efficiency.With a cutting power of 6000 watts, this cutting-edge laser machine is capable of handling a wide range of materials with unparalleled accuracy and speed. Whether it's metal, plastic, wood, or other industrial materials, the Laser 6000w delivers precise and clean cuts, making it an essential tool for various industries, including automotive, aerospace, and manufacturing.The company behind this innovation is known for its commitment to pushing the boundaries of laser technology. With years of experience and expertise, they have established themselves as a pioneer in the industry, constantly striving to develop cutting-edge solutions that cater to the evolving needs of their clients.The Laser 6000w is a testament to the company's dedication to innovation and excellence. Equipped with advanced features and a user-friendly interface, this machine offers unmatched versatility and performance. Its high-speed cutting capabilities enable it to tackle complex designs and intricate patterns with ease, while its precision ensures consistently high-quality results.In addition to its impressive cutting capabilities, the Laser 6000w is also designed with efficiency in mind. With its energy-efficient operation and minimal maintenance requirements, this machine offers a cost-effective solution for businesses looking to streamline their production processes and maximize their output.Furthermore, the company's commitment to customer satisfaction is reflected in the comprehensive support and service offerings that accompany the Laser 6000w. From installation and training to ongoing maintenance and technical support, the company ensures that their clients can harness the full potential of this cutting-edge technology.The introduction of the Laser 6000w is expected to have a significant impact on the laser cutting industry. With its unrivaled cutting power and efficiency, this machine has the potential to revolutionize the way materials are processed and fabricated, setting new standards for precision and productivity in the manufacturing sector.In conclusion, the Laser 6000w represents a significant milestone in the evolution of laser technology, and it is poised to make a lasting impact on the industry. With its advanced features, precision cutting capabilities, and commitment to customer satisfaction, this machine is set to elevate the standards of excellence in the world of laser cutting. The company's dedication to innovation and their track record of delivering cutting-edge solutions positions them as a leader in the industry and sets the stage for a new era of unparalleled efficiency and precision in material fabrication.

Powerful 100w Laser Co2 for Various Applications

Laser technology has taken a significant leap forward with the introduction of the Laser Co2 100w, a cutting-edge system that promises to revolutionize the industrial and medical sectors. The Laser Co2 100w is the latest offering from the renowned company, known for its innovative and high-quality laser solutions.With a focus on precision and efficiency, the Laser Co2 100w is designed to meet the diverse needs of industries such as automotive, aerospace, electronics, and medical device manufacturing. This powerful system delivers exceptional performance, allowing for precise cutting, engraving, and marking on a wide range of materials including metal, plastic, glass, and wood. Its advanced capabilities make it an invaluable tool for the production of intricate and high-quality parts and components.In addition to its industrial applications, the Laser Co2 100w also holds great promise in the medical field. With its ability to deliver precise and controlled energy, it is ideal for a variety of medical procedures including surgical cutting, ablation, and vaporization. This makes it a valuable tool for a range of medical specialties including dermatology, ophthalmology, and gynecology. The system's high level of precision and minimal thermal damage also make it well-suited for delicate procedures, further demonstrating its potential to enhance patient care and outcomes.The Laser Co2 100w is a testament to the company's commitment to advancing laser technology and pushing the boundaries of what is possible. With a strong focus on research and development, the company has consistently delivered innovative solutions that have set new standards in the industry. Its team of experts, including engineers, physicists, and materials scientists, work tirelessly to develop cutting-edge technologies that address the evolving needs of its diverse customer base.Having garnered a reputation for excellence, the company has established itself as a trusted partner for businesses and organizations seeking reliable and high-performance laser solutions. Its dedication to quality and customer satisfaction has earned it the trust of clients around the world, solidifying its position as a leader in the industry.Beyond its technical expertise, the company is also committed to sustainability and corporate responsibility. It ensures that its manufacturing processes are environmentally friendly and that its products are designed for maximum energy efficiency. This commitment to sustainability not only benefits the environment but also positions the company as a responsible and ethical partner in the eyes of its customers.In summary, the Laser Co2 100w represents a significant advancement in laser technology, with the potential to transform industries and enhance medical procedures. With its exceptional performance and versatility, it promises to deliver superior results in a wide range of applications. Coupled with the company's solid reputation for innovation and excellence, the Laser Co2 100w is poised to make a lasting impact in the world of laser technology.

Video highlights top features of CNC fiber laser cutting machines for metal materials

, CNC Fiber Laser, High Precision Cutting, Metal Cutting.In today's world, the demand for precision cutting has increased manifold. Be it in the manufacturing industry or the automobile sector, precision cutting is required in all areas of modern production. And with the advancement in technology, we have seen a significant change in the machines that are used for cutting metals.One of the most widely used machines for high precision cutting is the CNC fiber laser cutting machine. A CNC fiber laser cutting machine is a technological marvel that uses an advanced fiber laser generator and ball screw moving system to cut different kinds of metal with high precision and speed.CNC fiber laser cutting machines offer a competitive edge to businesses by increasing their productivity and efficiency. They are also easy to operate, and their maintenance or adjustment does not require much time or effort. In this blog post, we will delve into the features and benefits of CNC fiber laser cutting machines.High Precision Cutting with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their precision cutting capabilities. They use advanced fiber laser generator technology to produce a high-intensity laser beam, which is then used to cut the metal with great precision. CNC fiber laser cutting machines can cut through different thicknesses of metals, including stainless steel, carbon steel, and aluminum, with great accuracy.The precision cutting feature of CNC fiber laser cutting machines makes them a perfect tool for creating intricate shapes and patterns in metals. They are ideal for making complex cuts needed in industries like aerospace, manufacturing, and automotive.Increased Efficiency with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their high-speed operation. They can perform cuts at a much faster pace than other cutting machines in the market. The ball screw moving system used in CNC fiber laser cutting machines ensures that the machine moves smoothly and quickly, resulting in faster processing times.The high-speed operation of CNC fiber laser cutting machines makes them an ideal choice for businesses that need to cut a large number of metal pieces in a short amount of time. This efficiency helps businesses reduce their production times and increase their output.Low Maintenance and Easy to OperateAnother significant advantage of CNC fiber laser cutting machines is their low maintenance requirements. Since the laser is transmitted by fiber, there is no need for frequent maintenance or adjustments to the laser optical path. This reduces operational costs while ensuring consistent, high-quality results.CNC fiber laser cutting machines are also easy to operate. They come with user-friendly software that allows operators to design and execute precise cuts without any hassle. The software allows for customization of shapes and patterns, enabling greater design flexibility for businesses.ConclusionCNC fiber laser cutting machines are changing the way businesses cut metals today. Their high precision, speed, and efficiency have made them a preferred choice for industries that require precise cutting and fast processing times. Their low maintenance and ease of use have made them a cost-effective tool for businesses of all sizes.If you are looking for a machine that can cut metal with precision and speed while reducing your operational costs, CNC fiber laser cutting machines are the answer. Invest in a CNC fiber laser cutting machine today and experience the benefits firsthand!

Discover the Impact of CO2 Laser Voltage on [Industry/Process/Field]

Title: Cutting Edge CO2 Laser Voltage Technology Revolutionizes Industrial ApplicationsIntroduction:In an increasingly competitive industrial landscape, companies are constantly searching for innovative technologies to gain a competitive edge. Enter CO2 Laser Voltage, a groundbreaking solution that is poised to revolutionize industrial applications across various sectors. Developed by pioneering researchers and engineers, this cutting-edge technology promises to deliver unparalleled performance, efficiency, and precision for a wide range of manufacturing processes. Let's delve deeper into the features and potential applications of this remarkable advancement.Overview of CO2 Laser Voltage Technology:The CO2 Laser Voltage technology represents a significant milestone in the field of industrial laser solutions. Powered by breakthrough engineering, this innovative solution harnesses the power of carbon dioxide gas in a laser resonator to amplify voltage that substantially enhances the efficiency and performance of laser systems. Unlike conventional laser systems that rely on electricity, CO2 Laser Voltage offers substantial advantages in terms of power output, beam quality, and stability, making it an ideal choice for diverse industrial applications.Unleashing Unmatched Precision:One of the standout features of CO2 Laser Voltage technology is its ability to deliver unparalleled precision in industrial processes. The amplified voltage generated by this technology significantly enhances the laser's cutting, drilling, and marking capabilities. Manufacturers can now achieve unprecedented levels of precision, enabling them to create intricately detailed and accurate components. Industries such as automotive, aerospace, electronics, and medical devices stand to benefit from this enhanced precision, resulting in superior product quality and improved efficiency in production.Enhanced Efficiency for Industrial Processes:With CO2 Laser Voltage technology, manufacturers can expect a substantial boost in efficiency and productivity. By maximizing the efficiency of the laser system, this technology minimizes energy waste, reducing operating costs and optimizing production output. Compared to traditional laser systems, CO2 Laser Voltage offers significant energy savings, making it an eco-friendly choice that aligns with global sustainability goals. Additionally, the enhanced efficiency ensures faster production cycles, reducing lead times and enabling businesses to meet tight deadlines.Versatile Applications:The versatility of CO2 Laser Voltage technology makes it suitable for a wide array of industrial applications. In the automotive sector, it can be employed for efficient cutting and welding of components, resulting in improved vehicle safety and performance. The aerospace industry can benefit from this technology by achieving precise drilling and scribing of delicate materials used in aircraft construction. In the electronics industry, the high precision capabilities of CO2 Laser Voltage can enhance the fabrication of microcircuits and electrical components. Similarly, this technology finds applications in medical device manufacturing, enabling the production of intricate surgical instruments and implants.Company Spotlight:Leading the charge in CO2 Laser Voltage technology is our esteemed partner, a globally renowned industrial technology company that specializes in developing cutting-edge solutions to meet the evolving demands of the market. With decades of experience and a track record of excellence, the company has cemented its position as a pioneer in laser solutions. The introduction of CO2 Laser Voltage further solidifies its commitment to innovation and offering state-of-the-art technologies to drive industrial progress.Conclusion:With CO2 Laser Voltage technology, industrial applications are set to undergo a transformative change. The amplified voltage capability, unmatched precision, and enhanced efficiency provided by this innovative solution are poised to revolutionize manufacturing processes across industries. As more businesses adopt this breakthrough technology, they stand to gain a significant competitive advantage, bringing greater precision, productivity, and sustainability to their operations.