Understanding the Importance of a Hydraulic Machine in Industrial Operations

By:Admin

The new machine, which has been aptly named the "HydraTech 5000," represents the culmination of years of research and development by the company's team of engineers and experts. With its cutting-edge design and state-of-the-art technology, the HydraTech 5000 is poised to set a new standard for hydraulic equipment.

One of the key features of the HydraTech 5000 is its advanced hydraulic system, which has been engineered to deliver maximum power and efficiency. This system is the result of extensive testing and optimization, and is designed to meet the demanding requirements of modern industrial applications. Whether it's lifting heavy loads or powering complex machinery, the HydraTech 5000 is up to the task.

In addition to its impressive hydraulic system, the HydraTech 5000 also boasts a range of other innovative features. These include a robust and durable construction, which ensures that the machine can withstand the rigors of heavy-duty use. Furthermore, the HydraTech 5000 incorporates the latest safety technologies, providing operators with peace of mind and ensuring smooth and trouble-free operation.

The introduction of the HydraTech 5000 marks a significant milestone for Machine Hydraulic, and reflects the company's ongoing commitment to pushing the boundaries of hydraulic technology. With its unrivaled performance and reliability, the HydraTech 5000 is set to make a major impact in the industry, and is sure to become the go-to choice for businesses and organizations in need of high-quality hydraulic equipment.

Machine Hydraulic has a long and successful history in the field of hydraulic technology. Since its inception, the company has been at the forefront of innovation, constantly striving to develop new and improved solutions for its customers. This commitment to excellence has earned Machine Hydraulic a reputation for delivering products that consistently exceed expectations.

The company's success can be attributed to a number of factors, not least of which is its team of dedicated and passionate professionals. Machine Hydraulic employs some of the most talented engineers and experts in the industry, all of whom are driven by a shared goal of pushing the boundaries of what is possible in hydraulic technology. This culture of innovation and excellence is evident in the company's products, and is a key reason for its continued success.

Furthermore, Machine Hydraulic is committed to providing its customers with the highest levels of service and support. The company understands the importance of reliability and efficiency in the industrial sector, and works tirelessly to ensure that its products not only meet, but exceed, the expectations of its customers. This dedication to customer satisfaction has helped Machine Hydraulic build long-lasting relationships with businesses and organizations around the world.

Looking to the future, Machine Hydraulic is committed to continue pushing the boundaries of hydraulic technology, and to developing new and innovative solutions that will help its customers achieve their goals. With the introduction of the HydraTech 5000, the company has once again demonstrated its ability to lead the way in the hydraulic industry, and has set the stage for continued success and growth in the years to come.

Company News & Blog

Discover the Best CO2 Laser Cutter for Sale at Competitive Prices

Title: Advanced CO2 Laser Cutter Technology for Sale: Unlocking Precision and Efficiency in Manufacturing ProcessesIntroduction:In today's rapidly evolving manufacturing industry, businesses are constantly seeking cutting-edge technologies to enhance their production capabilities. The introduction of CO2 laser cutters has revolutionized the way various materials, including metals, plastics, and textiles, are processed, empowering businesses to achieve precise cuts with speed and efficiency. Recognizing the demand for such advanced equipment, (Company Name) is proud to announce the availability of their state-of-the-art CO2 laser cutter for sale, facilitating innovative manufacturing processes and increased productivity.Section 1: The Rising Demand for Precision Laser Cutting in ManufacturingIn recent years, there has been an exponential growth in the need for precise and high-speed cutting in various industries, such as automotive, electronics, signage, and apparel. Traditional cutting methods often fall short in terms of accuracy, cost-effectiveness, and versatility, prompting manufacturers to adopt CO2 laser cutters as their go-to solution. These cutters utilize a highly focused laser beam that allows for intricate and precise cuts, ensuring the highest quality end-products.Section 2: Unparalleled Features of (Company Name)'s CO2 Laser Cutter2.1 Cutting-edge Technology:(Company Name)'s CO2 laser cutter showcases the pinnacle of cutting-edge technology, providing manufacturers with a wide range of capabilities and exceptional performance. The cutter utilizes a high-powered CO2 laser that seamlessly cuts through various materials with utmost precision, from delicate fabrics to thick metals. This advanced technology significantly reduces production time, eliminates costly errors, and facilitates intricate designs.2.2 Customizable and Versatile:Recognizing the diverse needs of manufacturers, (Company Name)'s CO2 laser cutter offers unparalleled customization options. The machine can be optimized to suit specific requirements, ensuring optimal cutting performance across a broad spectrum of materials. This versatility empowers businesses to remain competitive in the ever-changing manufacturing landscape.2.3 Intuitive User Interface:Ease of use is an essential aspect that enhances productivity and reduces downtime in any manufacturing facility. Understanding this need, (Company Name) has developed an intuitive user interface for their CO2 laser cutter. With a user-friendly control panel and advanced software integration, operators can effortlessly navigate through the machine's functionalities, programming intricate designs, and executing precise cuts with minimal training.Section 3: The Benefits of Investing in (Company Name)'s CO2 Laser Cutter3.1 High Production Output:The adoption of CO2 laser cutters guarantees a significant boost in production output, thanks to their ability to cut through materials swiftly and accurately. Manufacturers can save valuable time, meet tight deadlines, and achieve increased profitability by incorporating this advanced technology into their operations.3.2 Reduction in Material Waste:Precision cutting with a CO2 laser cutter ensures minimal material waste. The highly focused laser beam leaves behind narrow kerf widths, resulting in higher material utilization rates. By reducing waste, businesses can lower operating costs, improve sustainability efforts, and contribute to a greener environment.3.3 Enhanced Product Quality:The precision offered by (Company Name)'s CO2 laser cutter elevates the quality of end-products to unprecedented levels. The clean cuts and minimal heat-affected zones ensure that materials retain their structural integrity, eliminating the need for post-processing and further enhancing the product's overall finish.Conclusion:The unveiling of (Company Name)'s advanced CO2 laser cutter for sale signifies a significant milestone in the manufacturing industry. With its cutting-edge technology, versatility, and unmatched precision, this equipment empowers businesses to streamline processes, increase production output, and elevate product quality. By investing in (Company Name)'s CO2 laser cutter, manufacturers can stay at the forefront of the industry, ensuring a competitive edge and future growth.

Expert Guide to Plate Cutting Techniques and Technology

Plate cutting is a crucial process in the manufacturing and construction industries, and it plays a vital role in shaping metal and other materials into precise and customized components. It is a highly specialized process that requires cutting-edge technology and expertise to ensure accuracy and efficiency. In this regard, {Company Name} has emerged as a leading provider of plate cutting services, offering state-of-the-art equipment and a team of skilled professionals to meet the diverse needs of its clients.{Company Name} is a renowned company in the field of metal fabrication, offering a wide range of services including plate cutting, welding, and custom fabrication. With years of experience and a commitment to excellence, {Company Name} has built a strong reputation for delivering high-quality solutions to its clients across various industries.The company takes pride in its advanced plate cutting capabilities, which are driven by the latest technology and innovative processes. It utilizes cutting-edge CNC machines that are capable of cutting various thicknesses and types of materials with unmatched precision and speed. Whether it is stainless steel, aluminum, or carbon steel, {Company Name} has the expertise and equipment to handle a wide range of materials, delivering precise and accurate cuts to meet the exact specifications of its clients.One of the key factors that set {Company Name} apart from its competitors is its ability to provide customized plate cutting solutions. The company understands that each project comes with its unique requirements, and its team works closely with clients to develop tailored cutting solutions that meet their specific needs. From intricate designs to large-scale components, {Company Name} has the capabilities to handle diverse cutting requirements, delivering superior results that exceed expectations.In addition to its cutting-edge technology, {Company Name} takes pride in its skilled professionals who bring a wealth of knowledge and expertise to every project. The company's team is highly trained and experienced in plate cutting techniques, ensuring that each job is executed with precision and efficiency. Furthermore, {Company Name} is committed to maintaining the highest quality standards in its operations, adhering to strict quality control measures to ensure that the final products meet the highest industry standards.{Company Name} serves a wide range of industries, including automotive, aerospace, construction, and manufacturing. Its plate cutting services are widely recognized for their precision, reliability, and versatility, making {Company Name} a preferred choice for clients with diverse cutting needs. Whether it is a small-scale prototype or a large-scale production run, {Company Name} has the capabilities and capacity to handle projects of any size and complexity, delivering top-notch results with a quick turnaround time.As {Company Name} continues to expand its plate cutting services, it remains committed to innovation and continuous improvement. The company invests in the latest technology and equipment to stay ahead of the curve, ensuring that its clients receive cutting-edge solutions that meet the evolving demands of the industry. With its unwavering focus on quality, precision, and customer satisfaction, {Company Name} is poised to maintain its leadership position in the plate cutting sector.In conclusion, plate cutting is a critical process in various industries, and {Company Name} has established itself as a trusted provider of cutting-edge plate cutting services. With its advanced technology, expertise, and commitment to excellence, {Company Name} offers customized cutting solutions that meet the diverse needs of its clients. Whether it is a small-scale project or a large-scale production run, {Company Name} has the capabilities and capacity to deliver superior results, making it a go-to choice for clients seeking reliable and efficient plate cutting services.

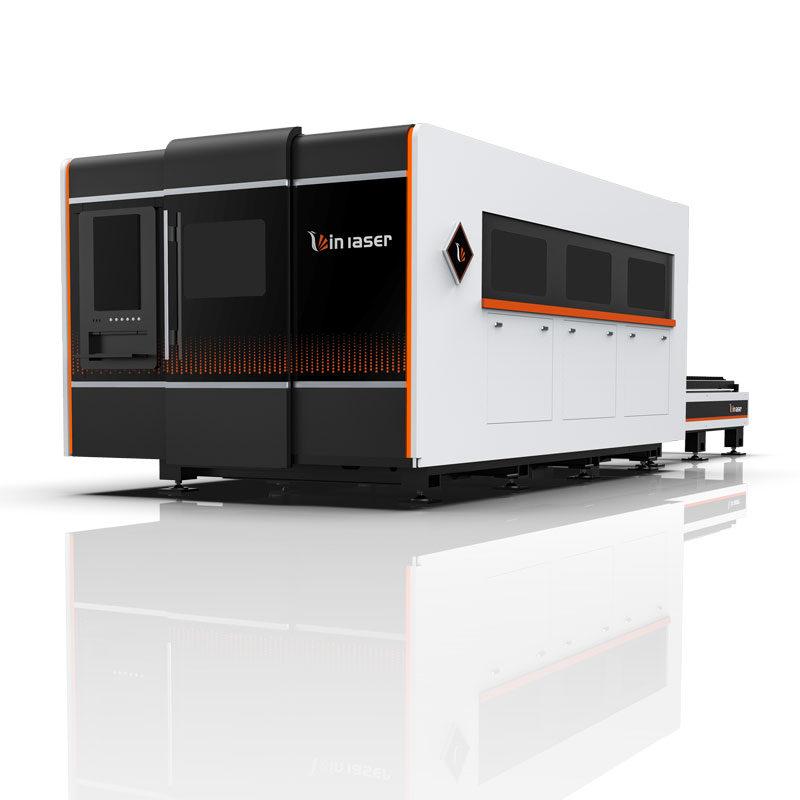

High Quality Fiber Laser Machines Now Available for Purchase

In today's rapidly advancing technological landscape, the demand for high-quality, efficient and reliable laser cutting machinery is on the rise. And in response to this demand, the renowned company {company introduction} is proud to announce the availability of their state-of-the-art Fiber Laser for sale. This cutting-edge machinery is designed to provide precision cutting solutions for a wide range of industrial applications, making it a valuable asset for businesses looking to enhance their production capabilities.The Fiber Laser for sale from {company introduction} is a testament to the company's commitment to delivering high-performance machinery that meets the evolving needs of their customers. With its advanced fiber laser technology, this cutting system offers unparalleled speed, accuracy, and reliability, making it an ideal choice for manufacturers and businesses across various industries.One of the key features of this Fiber Laser is its exceptional cutting precision. The cutting head is equipped with advanced optical components and cutting-edge software, allowing for precise control and accuracy in the cutting process. This level of precision is crucial for industries that require intricate and detailed cutting, such as the automotive, aerospace, and electronics sectors.Furthermore, the Fiber Laser for sale is designed to be highly efficient, thanks to its energy-efficient fiber laser technology. This allows for cost-effective operation, reduced energy consumption, and lower maintenance costs, making it a compelling choice for businesses looking to optimize their production processes and enhance their bottom line.In addition to its precision and efficiency, the Fiber Laser for sale from {company introduction} is also known for its versatility. It is capable of cutting a wide range of materials, including metals, plastics, and composites, allowing businesses to streamline their cutting processes and accommodate diverse manufacturing requirements.The Fiber Laser is also designed with user-friendly features, such as intuitive controls and a user-friendly interface, allowing operators to easily set up and operate the machinery with minimal training. This makes it a valuable investment for businesses looking to enhance their productivity and efficiency without the need for extensive training or expertise in laser cutting technology.As a company with a strong commitment to customer satisfaction, {company introduction} also offers comprehensive training, support, and maintenance services for their Fiber Laser for sale. This ensures that customers can maximize the efficiency and performance of the machinery, while also receiving prompt assistance and support in the event of any issues or technical challenges.With the availability of their Fiber Laser for sale, {company introduction} reaffirms its position as a leading provider of cutting-edge laser cutting solutions for businesses across various industries. The company's dedication to innovation, quality, and customer satisfaction is evident in this cutting-edge machinery, which represents a compelling opportunity for businesses seeking to enhance their cutting capabilities and stay ahead in today's competitive market.Overall, the Fiber Laser for sale from {company introduction} is a testament to the company's commitment to delivering high-quality, efficient, and reliable cutting solutions for businesses looking to optimize their production processes and stay ahead of the competition. With its advanced technology, precision cutting capabilities, and user-friendly features, this cutting-edge machinery is set to make a significant impact in the industrial sector, offering businesses a valuable asset for enhancing their manufacturing capabilities and achieving greater operational efficiency.

The Benefits of Plate Laser Technology for Cutting and Engraving

Advanced Laser Technology Revolutionizes Manufacturing IndustryIn a breakthrough for the manufacturing industry, a cutting-edge plate laser technology is set to revolutionize the way companies process and cut metal and other materials. Developed by a leading industrial technology company, this revolutionary plate laser system offers precision cutting capabilities and unmatched efficiency, setting a new standard in the field of laser processing.The introduction of the plate laser system is expected to have a significant impact on various industries, including automotive, aerospace, and industrial manufacturing. With its advanced features and capabilities, this technology is set to streamline production processes, improve quality, and reduce manufacturing costs for companies worldwide.At the core of the plate laser system is its state-of-the-art laser cutting technology, which allows for the precise and efficient cutting of a wide range of materials, including steel, aluminum, and stainless steel. The system is equipped with high-power lasers that can easily handle thick materials with ease, ensuring clean and accurate cuts every time.One of the key advantages of the plate laser system is its ability to perform complex cuts and intricate designs with unparalleled precision. This level of precision and accuracy is crucial for industries that require high-quality parts and components, such as the aerospace and automotive sectors.Furthermore, the plate laser system comes with advanced software and automation features that enable seamless integration with existing manufacturing processes. This not only simplifies the production process but also helps to reduce the risk of errors and increase overall efficiency.In addition to its cutting capabilities, the plate laser system also offers a range of additional features designed to enhance the overall manufacturing process. These include the ability to mark and engrave materials, as well as the option to perform other surface treatments, all within a single system.Moreover, the plate laser system is designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up and utilize the system with minimal training. This ensures a smooth transition for companies looking to integrate this cutting-edge technology into their production facilities.As a result of these advanced features and capabilities, the plate laser system has the potential to significantly improve the competitiveness of companies operating in the manufacturing industry. By enhancing the speed, accuracy, and flexibility of their production processes, companies can stay ahead of the curve and meet the evolving demands of their customers.The introduction of the plate laser system is a testament to the commitment of the company to push the boundaries of innovation and technology in the manufacturing industry. With a strong emphasis on research and development, the company has been at the forefront of developing cutting-edge solutions that address the evolving needs of the market.Through its extensive industry expertise and a dedication to excellence, the company has established itself as a trusted partner for companies seeking to enhance their manufacturing capabilities. With a global presence and a reputation for delivering high-quality solutions, the company is well-positioned to drive the adoption of advanced laser technology in the manufacturing industry.As the manufacturing industry continues to evolve, the demand for advanced technologies that can deliver speed, precision, and efficiency will only continue to grow. With its remarkable plate laser system, the company is paving the way for a new era of manufacturing, where innovation and technology converge to shape the future of production processes.

Cost-effective Rust Removal: How Laser Technology is Revolutionizing Metal Cleaning

Laser Rust Removal: A Cost-effective Solution for Cleaning MetalRust is an inevitable problem that occurs on metal surfaces over time. Rust not only affects the appearance of metal, but it also weakens it and reduces its lifespan. Traditional rust removal methods, such as sandblasting and chemical solutions, are not only time-consuming but also harm the environment. However, advancements in technology have introduced a new cost-effective solution for cleaning metal: laser rust removal.Laser cleaning for metal is an incredible technique that involves the application of a high-energy laser beam to remove rust from metal surfaces. It is a non-contact process that does not require any abrasive or chemical solutions. The laser beam gently removes rust from the metal surface and leaves it clean and free of any debris. This method is incredibly efficient and effective at cleaning metal surfaces without any damage or distortion.One of the biggest advantages of laser rust removal is that it is a green technology. Laser cleaning for metal does not produce any harmful waste or toxic fumes during the process. It is an eco-friendly and sustainable method of rust removal, which makes it an ideal choice for industries that prioritize sustainability.Moreover, laser cleaning for metal is a faster and cost-effective method compared to other traditional cleaning methods. It is incredibly efficient and can quickly clean large areas in a short amount of time. As this process does not require expensive consumables, such as sand or chemicals, it is a cost-effective solution for anyone.Laser rust removal can also help to extend the lifespan of metal structures and equipment. Rust weakens metal structures and reduces their load-carrying capacity. By removing rust from metal surfaces, laser cleaning for metal can help to restore the original strength of the structures and equipment, increasing their lifespan.Another advantage of laser cleaning for metal is that it is incredibly versatile and can handle different types of metals, such as iron, brass, copper, and aluminum. The laser beam can adjust to different surface finishes and remove rust without damaging the metal surface.In conclusion, laser rust removal is an innovative technology that provides a cost-effective and eco-friendly solution for cleaning metal surfaces. It is faster, efficient, and sustainable compared to traditional rust removal methods. This technology is ideal for industries that prioritize sustainability and want to reduce their carbon footprint. Laser cleaning for metal is a great investment for those who want to prolong the lifespan of their metal equipment and structures while maintaining their quality and appearance. Choose laser cleaning for metal, and you'll have a rust-free metal surface that is not only clean and aesthetically pleasing but also strong and durable.Keywords: Laser Cleaner For Metal, Laser Rust Removal, Cost-effective Solution, Cleaning Metal.

Revolutionizing Welding Technology: Discover the Power of Portable Laser Welding Machines

Portable Laser Welding Machine: The Revolutionary Solution for Welding NeedsWelding has been an essential part of manufacturing and construction industries for decades. However, traditional welding methods require a substantial amount of time, cost, and effort, which can be inefficient and laborious. With the advancements in technology, the Portable Laser Welding Machine has emerged as a game-changer in the world of welding.This revolutionary invention has the potential to improve the efficiency, accuracy and precision of welding processes, as well as offer cost-effective solutions in various industries. The Portable Laser Welding Machine is a highly precise and innovative tool that uses a concentrated beam of laser light to weld metal together. This machine is a small, lightweight and portable device that can easily be carried to different locations.What sets the Portable Laser Welding Machine apart from conventional welding methods is its incredibly fast and efficient nature. The laser beam is capable of penetrating the metal and creating a deep weld in just a matter of seconds. The precision of the machine ensures that there is minimal splattering and distortion, making it an ideal choice for applications that require clean and accurate welds.With its innovative design, the Portable Laser Welding Machine offers several advantages over traditional welding methods. Unlike conventional welding techniques, laser welding does not require any filler material, which drastically reduces the cost and time spent on welding. The machine can weld a wide range of metals, including stainless steel, aluminum, and titanium, making it a versatile tool for a variety of industries.The Portable Laser Welding Machine is also highly efficient and requires minimal maintenance. Unlike traditional welding equipment, this device does not require any gas supply or compressed air, which significantly reduces the cost of operation and eliminates the risk of gas leaks. The machine is also self-contained and can be operated by a single person, which saves time and labor costs.As one of the leading manufacturers of Portable Laser Welding Machines, we have been providing innovative and high-quality solutions to our clients for over a decade. Our machines are designed and manufactured using cutting-edge technology and the highest quality materials. Each machine undergoes rigorous testing and quality control checks to ensure that it meets the highest industry standards.We offer a range of portable laser welding machines to cater to the different needs of our customers. Our machines are designed to be user-friendly and offer ease of operation. Whether you need to weld small components or large structures, our machines can handle any task with precision and efficiency.Our machines are also highly customizable, and we offer a range of accessories and add-ons to enhance their functionality. From laser probes and rotating chucks to automatic wire feeders and tracing systems, we have a range of options to suit your specific welding needs.In conclusion, the Portable Laser Welding Machine is a revolutionary tool that offers several benefits over traditional welding methods. With its precision, efficiency, cost-effectiveness and versatility, it has become an indispensable tool in several industries, including construction, automotive, aerospace, and medical. As one of the leading manufacturers of portable laser welding machines, we are committed to providing our customers with high-quality and innovative welding solutions to meet their needs.

Revolutionary Automated Pipe Welder Takes Industry by Storm

Automated Pipe Welder Revolutionizing the Welding IndustryIn today’s fast-paced manufacturing industry, companies are constantly seeking innovative solutions to increase productivity and efficiency. One such solution that is revolutionizing the welding industry is the Automated Pipe Welder, developed by a leading manufacturing company. With its advanced technology and precision engineering, this cutting-edge machine is transforming the way pipes are welded, leading to faster production times and higher quality welds.The Automated Pipe Welder is equipped with state-of-the-art robotic arms and welding equipment, allowing it to perform complex and precise welds with minimal human intervention. This not only reduces the risk of human error but also improves the consistency and quality of the welds, resulting in stronger and more reliable pipe joints. In addition, the machine’s automation capabilities allow for increased productivity, as it can work continuously without the need for frequent breaks or rest periods.One of the key advantages of the Automated Pipe Welder is its ability to weld pipes of various sizes and materials, including carbon steel, stainless steel, and alloy steel. This versatility makes it an invaluable tool for a wide range of industries, including oil and gas, power generation, chemical processing, and construction. The machine’s ability to adapt to different welding requirements ensures that companies can meet the demands of diverse projects without the need for multiple specialized welding machines.Furthermore, the Automated Pipe Welder is designed to enhance workplace safety by reducing the need for manual welding in hazardous environments. By automating the welding process, the risk of injuries and accidents associated with manual welding is significantly minimized, creating a safer work environment for employees. This is particularly important in industries such as oil and gas, where welding is often carried out in challenging and high-risk conditions.The company behind the development of the Automated Pipe Welder is a renowned leader in the manufacturing and engineering industry, with a strong track record of delivering cutting-edge solutions to its clients. With a focus on innovation and customer satisfaction, the company has invested heavily in research and development to create advanced welding technologies that meet the evolving needs of the industry. The introduction of the Automated Pipe Welder is a testament to the company’s commitment to driving progress and efficiency in welding processes.In addition to its technological expertise, the company is also known for its exceptional customer support and after-sales service. This ensures that clients who invest in the Automated Pipe Welder receive comprehensive training, technical assistance, and maintenance support to maximize the machine’s performance and longevity. The company’s dedication to building long-term partnerships with its clients has earned it a reputation as a trusted and reliable provider of welding solutions.As the demand for efficient and high-quality welding solutions continues to rise, the Automated Pipe Welder is poised to play a pivotal role in shaping the future of the welding industry. Its innovative technology, coupled with the expertise and support offered by the company, makes it a game-changing asset for manufacturers and construction companies worldwide. By streamlining welding processes, improving weld quality, and enhancing workplace safety, the Automated Pipe Welder is paving the way for a new era of excellence in the welding industry.

Efficient Laser Machine for Precise Gold Cutting: Top Features Your Business Needs to Look For

Title: Industry-Leading Gold Cutting Laser Machine Revolutionizes Jewelry ManufacturingIntroduction:In a groundbreaking development for the jewelry manufacturing industry, a pioneering company, known for its excellence in laser technology, has introduced the latest version of its Gold Cutting Laser Machine. This state-of-the-art equipment encompasses cutting-edge features and precision, poised to transform the way jewelry is manufactured. Equipped with advanced optics and intelligent software, it promises to streamline production processes while maintaining impeccable quality standards. This revolutionary addition to the company's portfolio is set to redefine the future of gold jewelry production globally.Paragraph 1:The Gold Cutting Laser Machine is the result of years of research and development by the renowned laser technology experts at [Company Name]. By combining their extensive knowledge of laser machinery with an in-depth understanding of the jewelry manufacturing industry, [Company Name] has designed a cutting-edge product that addresses the complexities and demands of this sector. This machine ensures high precision and accuracy during the intricate gold cutting process, allowing jewelry designers and manufacturers to create intricate and delicate patterns effortlessly.Paragraph 2:At the core of this revolutionary machine lies its advanced optics system, which guarantees unparalleled efficacy in gold cutting. The laser beam emitted by the machine is focused to an incredibly small point size, enabling precise and intricate cuts on gold sheets or blanks. Whether creating unique designs or replicating complex patterns, the machine produces flawless results with minimal material loss, saving both time and cost for manufacturers. This cutting-edge technology eliminates the need for traditional jewelry manufacturing techniques, such as sawing or hand cutting, thus boosting overall efficiency and productivity.Paragraph 3:To further enhance the machine's capabilities, [Company Name] has integrated intelligent software that seamlessly integrates with existing design software used by jewelry designers. This software enables users to import their digital designs directly into the machine, ensuring a precise replication of the pattern onto the gold surface. The Gold Cutting Laser Machine's software accurately interprets the intricate details of the design, making it possible to create highly customized and unique jewelry pieces that were previously challenging to manufacture manually.Paragraph 4:Moreover, this innovative machine supports a wide range of gold thicknesses, providing manufacturers with greater flexibility and adaptability. The machine's automatic thickness detection feature ensures optimal settings for every gold sheet, saving time that would otherwise be spent calibrating the machine for each piece. The Gold Cutting Laser Machine maintains consistent cutting quality across various gold thicknesses, granting jewelry manufacturers increased confidence and eliminating production inconsistencies.Paragraph 5:Safety has been a major consideration during the development of the Gold Cutting Laser Machine. Incorporating rigorous safety measures and protocols, this equipment ensures both operator and machine safety. With features such as automated shut-off mechanisms, real-time monitoring of the cutting process, temperature sensors, and fire suppression systems, [Company Name] has prioritized the well-being of its users while maintaining utmost precision and efficiency during production.Conclusion:The introduction of the Gold Cutting Laser Machine by [Company Name] marks a significant milestone in the jewelry manufacturing industry. With its breakthrough technology, advanced optics system, intelligent software, and emphasis on safety, this state-of-the-art machine is set to revolutionize the way gold jewelry is cut and manufactured. Offering unmatched precision, efficiency, and customization options, [Company Name] continues to push the boundaries of laser technology, facilitating the creation of exquisite jewelry that exceeds customer expectations worldwide.

Powerful Quasi Continuous Wavelength Fiber Laser for Precision Applications

In today's modern manufacturing processes, lasers have become a go-to tool for various applications. Among the many types of lasers available, the 150w Fiber Laser is now gaining popularity in the industrial sector.The 150w Fiber Laser is a Quasi Continuous Wavelength Fiber Laser that offers great advantages in many applications, including Laser cutting, Laser welding, 3D printing, Precision drilling, and many others. Compared to other types of lasers, the 150w Fiber Laser is known for its high-speed processing, precision, and efficiency.The 150w Fiber Laser's standout feature is its impressive cutting and welding abilities. It can cut through thick sheets of metal and other materials with ease, thanks to its powerful beam and stable output. Its precision is also noteworthy, as it is capable of producing even the most intricate and delicate cuts with high accuracy.In Laser welding applications, the 150w Fiber Laser can produce clean and precise welds with minimal to no distortion, making it ideal for welding components in various industries. Its high-speed processing also makes it an excellent choice for carrying out 3D printing and Precision drilling applications.Moreover, the 150w Fiber Laser is relatively easy to operate and maintain, with a long life expectancy, making it a cost-effective choice for businesses of various sizes. It also has a small footprint, making it ideal for smaller workspaces.The 150w Fiber Laser is available from various manufacturers, including reputable brands like JPT Laser. JPT Laser offers a range of Quasi Continuous Wavelength Fiber Lasers, including the QCW 150/1500W – a highly efficient and versatile laser that is ideal for various industrial applications.In conclusion, the 150w Fiber Laser is an impressive and valuable tool in today's industrial sector. Its high-speed processing, accuracy, and efficiency make it a go-to option for various cutting, welding, and drilling applications. As businesses continue to seek ways to enhance their manufacturing processes, the 150w Fiber Laser is expected to see increasing demand in the years to come.

New Technology Breakthrough in Pipe Manufacturing

Machine Pipe, a leading manufacturer in the field of industrial piping solutions, has been making waves in the industry with their innovative products and exemplary service. With a commitment to providing high-quality and reliable piping solutions, Machine Pipe has become a trusted name in the industry.The company has a strong focus on research and development, constantly seeking new materials and technologies to improve their products. This dedication to innovation has led to the development of a range of cutting-edge piping solutions that are known for their durability, efficiency, and cost-effectiveness. This has allowed Machine Pipe to establish a strong presence in the market, catering to a wide range of industries including oil and gas, chemical, water treatment, and more.One of the company's most notable products is their advanced pipe fitting system, which has been widely acclaimed for its superior performance and ease of installation. This system is designed to meet the diverse needs of industrial applications, offering a wide range of fittings and accessories that are compatible with various piping materials. This versatility allows customers to tailor their piping systems to their specific requirements, ensuring optimum performance and longevity.In addition to their innovative product range, Machine Pipe is also known for their exceptional customer service. The company takes pride in providing comprehensive support to their clients, offering expert advice, technical assistance, and after-sales service. This commitment to customer satisfaction has helped Machine Pipe build long-lasting relationships with their clients, earning them a reputation for reliability and trustworthiness.Machine Pipe's dedication to quality and excellence has not gone unnoticed, as the company has received numerous accolades and certifications for their products and services. Their commitment to environmental sustainability and safety standards has also been recognized, further solidifying their position as an industry leader.In a recent development, Machine Pipe has announced the launch of a new range of piping solutions that are set to revolutionize the industry. This new range features state-of-the-art materials and advanced technologies that are designed to meet the evolving needs of modern industrial applications. With a focus on performance, efficiency, and sustainability, these new products are expected to set a new standard in the industry.The company's spokesperson stated, "We are thrilled to introduce our latest range of piping solutions, which are the result of years of research and development. We believe that these products will offer unmatched performance and reliability, setting a new benchmark in the industry."The introduction of these new products is expected to further solidify Machine Pipe's position as a market leader, catering to the growing demand for high-quality and sustainable piping solutions. With their track record of excellence and commitment to innovation, Machine Pipe is well-positioned to continue serving as a trusted partner for industries around the world.As Machine Pipe continues to push the boundaries of innovation and excellence, the company remains committed to their core values of quality, reliability, and customer satisfaction. With their unparalleled expertise and dedication, Machine Pipe is set to maintain their position as a leader in the field of industrial piping solutions for years to come.