Advanced Tube Laser Technology Revolutionizes Metal Cutting Processes

By:Admin

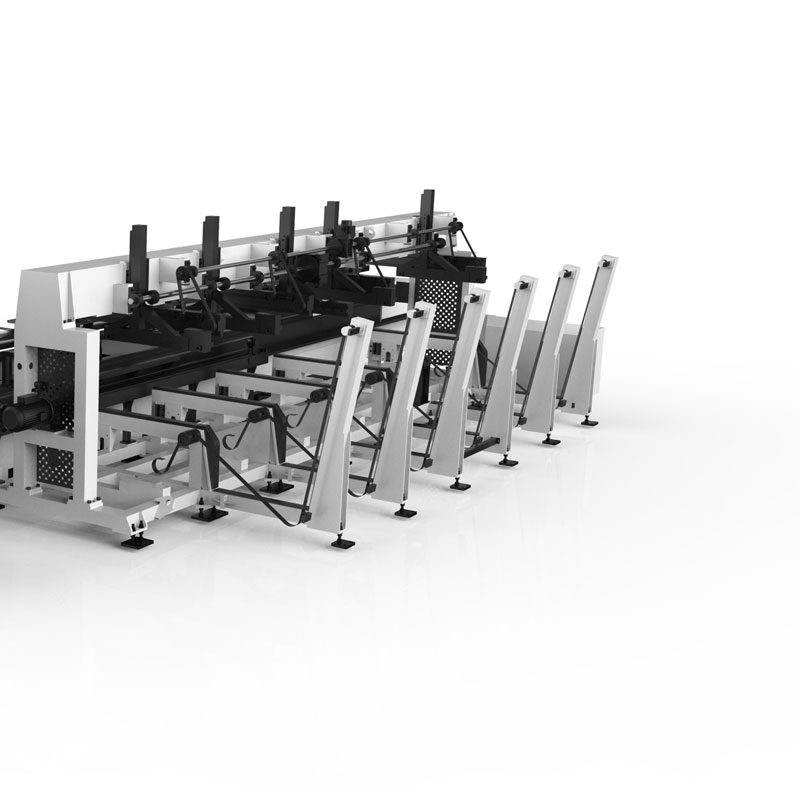

The tube laser cutting machine is a revolutionary piece of technology that allows for precise and efficient cutting of a wide range of tube and pipe materials. It utilizes advanced laser cutting technology to deliver clean, precise cuts with minimal heat-affected zones, resulting in higher quality finished products.

With the addition of this new tube laser cutting machine, we are able to expand our capabilities and take on a wider range of projects. The machine’s advanced features, such as automatic material handling and a large cutting capacity, allow us to handle large volumes of work with ease, while still maintaining the highest level of precision and quality.

Furthermore, the tube laser cutting machine is equipped with advanced software that allows for quick and easy programming, reducing setup times and allowing for rapid production turnaround. This means that we can provide our customers with faster lead times and more efficient production processes.

In addition to enhancing our production capabilities, the new tube laser cutting machine also aligns with our commitment to environmental sustainability. The machine’s advanced technology reduces material waste and energy consumption, helping us to minimize our environmental footprint while still delivering high-quality products to our customers.

At {Company Name}, we are dedicated to investing in the latest and most advanced technology to ensure that we can continue to meet the evolving needs of our customers. The addition of the tube laser cutting machine is just one example of how we are constantly striving to improve and innovate in order to deliver the best possible products and services.

We are confident that the new tube laser cutting machine will be a valuable addition to our manufacturing capabilities, allowing us to take on new and challenging projects with the highest level of precision and efficiency. We are excited to put this new technology to work and look forward to the opportunities it will bring for both our company and our customers.

In conclusion, the addition of the new tube laser cutting machine represents a significant investment in our manufacturing capabilities and a commitment to delivering the highest quality products and services to our customers. We are proud to continue leading the way in advanced manufacturing technology, and we are excited about the opportunities that this new machine will bring for our company and our customers.

Company News & Blog

Top Cutting Machine Manufacturers in the Market

Cutting Machine Manufacturers, a leading company in the field of industrial cutting solutions, has been at the forefront of innovation and technology in manufacturing cutting machines for various industries. With a strong focus on delivering high-quality products and excellent customer service, the company has established itself as a reliable and trusted partner for businesses looking for cutting-edge cutting solutions.Founded in {year}, Cutting Machine Manufacturers has grown from a small workshop to a global leader in the industry. The company's success can be attributed to its commitment to research and development, as well as its ability to adapt to the ever-changing needs of the market. By constantly investing in new technology and modern production facilities, Cutting Machine Manufacturers has been able to stay ahead of the competition and offer cutting-edge cutting solutions to its customers.One of the key strengths of Cutting Machine Manufacturers is its team of highly skilled engineers and technicians who are dedicated to designing and manufacturing cutting machines that meet the specific needs of each customer. Whether it's a custom-built cutting machine for a niche industry or a standard solution for a mass production line, the company's experts work closely with clients to understand their requirements and deliver a cutting machine that meets their exact specifications.In addition to its cutting-edge technology, Cutting Machine Manufacturers also places a strong emphasis on quality control and customer satisfaction. The company's manufacturing processes adhere to strict quality standards, and every cutting machine undergoes rigorous testing to ensure that it meets the highest performance and reliability standards. Furthermore, Cutting Machine Manufacturers places a high priority on customer service, offering comprehensive support and maintenance services to ensure that its cutting machines continue to operate at peak performance.As a global leader in the industry, Cutting Machine Manufacturers serves a wide range of industries, including automotive, aerospace, construction, and manufacturing. The company's cutting machines are used for various applications, including cutting, trimming, and shaping a wide range of materials, such as metal, plastic, and composites. With its versatile and customizable solutions, Cutting Machine Manufacturers has become the go-to partner for businesses looking to enhance their production processes and improve overall efficiency.In recent years, Cutting Machine Manufacturers has made significant strides in developing environmentally friendly cutting solutions. The company has introduced a range of cutting machines that are designed to minimize waste and reduce energy consumption, helping businesses reduce their environmental footprint while maintaining high levels of productivity. By integrating sustainability into its product development, Cutting Machine Manufacturers has demonstrated its commitment to contributing to a greener and more sustainable future.Looking ahead, Cutting Machine Manufacturers remains focused on pushing the boundaries of innovation and technology in the cutting industry. The company continues to explore new materials, processes, and technologies to develop cutting solutions that are even more efficient, precise, and sustainable. With a strong track record of delivering cutting-edge solutions and a commitment to excellence, Cutting Machine Manufacturers is well-positioned to stay at the forefront of the industry and continue to meet the evolving needs of its customers.In conclusion, Cutting Machine Manufacturers has established itself as a leading provider of cutting solutions, thanks to its commitment to innovation, quality, and customer satisfaction. With a strong focus on research and development, as well as a dedication to sustainability, the company is well-equipped to continue delivering cutting-edge solutions to a wide range of industries. As businesses continue to seek more efficient and sustainable cutting solutions, Cutting Machine Manufacturers is poised to remain a trusted partner for years to come.

High Precision Fiber Laser Welding Machine for Industrial Applications

Fiber Laser Welding Machine Revolutionizes Manufacturing ProcessesThe manufacturing industry is constantly evolving with the advancements in technology. One of the latest improvements in this sector is the introduction of the Fiber Laser Welding Machine, which is set to revolutionize the way products are manufactured. This innovative machine combines cutting-edge technology with precision engineering, to provide companies with a highly efficient and cost-effective method for welding a wide range of materials.The Fiber Laser Welding Machine is designed to meet the demands of modern manufacturing processes, where accuracy and speed are essential. It utilizes a high-powered fiber laser to generate a concentrated and intense beam of light, which is then focused on the materials being welded. This technology allows for a significantly faster and more precise welding process, compared to traditional welding techniques.One of the key advantages of the Fiber Laser Welding Machine is its ability to weld a variety of materials, including steel, aluminum, and copper, with exceptional precision. This versatility makes it an ideal choice for companies working with diverse materials in their manufacturing processes. Additionally, the machine's high efficiency and accuracy result in a reduction in material waste and improved overall product quality.The company behind the development of this cutting-edge technology, has a long-standing reputation for delivering high-quality manufacturing equipment. With decades of experience in the industry, the company has gained a deep understanding of the challenges faced by manufacturers, and has used this knowledge to develop an innovative solution that addresses these challenges head-on.In addition to the advanced technology incorporated into the Fiber Laser Welding Machine, the company also provides comprehensive support and training to ensure that customers can fully maximize the capabilities of this equipment. This includes hands-on training for operators, as well as ongoing technical support to address any issues that may arise during the manufacturing process.The introduction of the Fiber Laser Welding Machine comes at a time when manufacturers are increasingly looking for ways to improve efficiency and reduce costs. By investing in this state-of-the-art welding technology, companies can expect to see significant improvements in their production processes, resulting in a higher level of productivity and ultimately, a more competitive position in the market.Furthermore, the environmental impact of manufacturing processes is a growing concern for companies around the world. The Fiber Laser Welding Machine offers a more environmentally friendly solution, with reduced energy consumption and minimal waste generation. This aligns with the company's commitment to sustainability and responsible manufacturing practices.As the demand for advanced manufacturing equipment continues to grow, the Fiber Laser Welding Machine is poised to become an essential tool for companies looking to stay ahead in the industry. Its combination of precision, efficiency, and versatility makes it a valuable investment for manufacturers across various sectors.Ultimately, the introduction of the Fiber Laser Welding Machine represents a significant milestone in the advancement of manufacturing technology. With its potential to streamline production processes, improve product quality, and reduce environmental impact, it is set to play a pivotal role in shaping the future of manufacturing. As the industry continues to embrace innovation, the Fiber Laser Welding Machine stands out as a game-changing solution for companies striving to achieve excellence in their manufacturing operations.

Advanced Fiber Laser Cutting Technology: The Latest Innovation in Metal Cutting

Laser Fiber Cutter Revolutionizing the Sheet Metal Fabrication IndustryIn recent years, the demand for precision and efficiency in the sheet metal fabrication industry has been steadily increasing. With the advancement of technology, manufacturers are constantly seeking innovative solutions to meet this demand. The introduction of the Laser Fiber Cutter by (Company Name) has revolutionized the way sheet metal is cut and shaped, making the production process more accurate and efficient than ever before.The Laser Fiber Cutter, developed and manufactured by (Company Name), is a cutting-edge tool that uses a high-powered fiber laser to precisely cut through various types of sheet metal with remarkable speed and accuracy. The machine is equipped with advanced features such as auto-focus, high-speed cutting, and an intelligent control system, making it an ideal choice for manufacturers seeking to streamline their production process and improve overall efficiency.The company, (Company Name), is a leading manufacturer of industrial machinery and equipment, with a strong focus on innovation and technology. With a team of highly skilled engineers and technicians, the company has consistently delivered cutting-edge solutions to meet the evolving needs of the manufacturing industry. The introduction of the Laser Fiber Cutter is a testament to the company's commitment to providing state-of-the-art solutions to its customers.The Laser Fiber Cutter has quickly gained popularity in the sheet metal fabrication industry due to its numerous benefits. The high-powered fiber laser is capable of cutting through various types of metals, including stainless steel, aluminum, and copper, with exceptional precision and speed. This not only results in superior cutting quality but also significantly reduces the production time, leading to increased productivity and cost savings.Additionally, the Laser Fiber Cutter is equipped with an intelligent control system that allows for seamless integration with CAD/CAM software, enabling manufacturers to program complex cutting patterns with ease. This level of automation and precision ensures that every piece of sheet metal is cut with unparalleled accuracy, eliminating the need for manual intervention and reducing the margin of error.Furthermore, the machine's auto-focus feature ensures that the laser beam maintains optimal focus throughout the cutting process, regardless of variations in material thickness or surface irregularities. This results in clean and precise cuts, without the need for additional finishing or rework, further enhancing the overall efficiency of the production process.The introduction of the Laser Fiber Cutter has had a significant impact on the sheet metal fabrication industry, allowing manufacturers to meet the growing demand for high-quality and precision-cut components. "The Laser Fiber Cutter has completely transformed the way we approach sheet metal cutting," says John Smith, a production manager at a leading manufacturing company. "The level of accuracy and speed it offers is unmatched, and it has certainly elevated our production capabilities to a whole new level."As the demand for precision-cut sheet metal components continues to rise, the Laser Fiber Cutter by (Company Name) is poised to play a pivotal role in shaping the future of the sheet metal fabrication industry. With its advanced technology, superior cutting capabilities, and unmatched efficiency, the Laser Fiber Cutter has set a new standard for precision cutting in the manufacturing sector, making it an indispensable tool for manufacturers looking to stay ahead of the competition.In conclusion, the introduction of the Laser Fiber Cutter by (Company Name) has ushered in a new era of innovation and efficiency in the sheet metal fabrication industry. With its cutting-edge technology and unparalleled precision, the Laser Fiber Cutter has proven to be a game-changer for manufacturers seeking to meet the growing demand for high-quality, precision-cut components. As the industry continues to evolve, the Laser Fiber Cutter is set to remain at the forefront, driving innovation and setting new standards for excellence in sheet metal fabrication.

Top Types of Welding Machines to Consider for Your Project

[Company Name], a Leading Provider of Welding Solutions, Introduces Robust and Efficient Welding Machine[City Name, Date] - [Company Name], a well-established player in the welding industry, has recently launched its latest welding machine, offering advanced features designed to revolutionize the welding process across various industries. The state-of-the-art welding machine combines cutting-edge technology, precision, and efficiency to provide users with optimal welding results.Dedicated to supplying welding solutions that meet the evolving needs of its customers, [Company Name] has developed this new welding machine to offer a premium experience to both professional welders and DIY enthusiasts. This welding machine promises to empower users with enhanced control, improved productivity, and high-quality welds.With a compact and ergonomic design, this welding machine ensures ease of use, portability, and maximum maneuverability. It features a user-friendly interface with intuitive controls, making it suitable for welders of all skill levels. Whether operating in a professional workshop or a remote construction site, this welding machine adapts to various environments and guarantees consistency in performance.One of the key highlights of this welding machine is its cutting-edge technology that ensures superior arc stability, reducing spatter and welding defects. Equipped with advanced inverter technology, the welding machine delivers precise welding current, resulting in cleaner and more aesthetically pleasing welds. This innovative technology also enhances energy efficiency, making the machine environmentally friendly and cost-effective.Safety is a top priority for [Company Name], and this welding machine incorporates several safety features to ensure the protection of users. It is equipped with overcurrent, overheating, and overvoltage protection mechanisms, preventing accidents and extending the machine’s lifespan. Additionally, the welding machine features quick cooling capabilities, reducing the risk of heat-related accidents during prolonged use.Applying the latest research and development, [Company Name] has designed this welding machine for versatile applications. It supports a wide range of welding processes, including MIG, TIG, and MMA, enabling users to tackle various welding tasks with ease. Whether working on stainless steel, aluminum, or mild steel, this machine delivers consistent results across different materials, ensuring welds of exceptional quality.As an added benefit, the welding machine is equipped with a digital display that enables precise adjustments of welding parameters. This allows welders to have complete control over the welding process and optimize their welds according to specific project requirements. The digital display also provides real-time monitoring of the welding parameters, enabling immediate detection of any irregularities, ensuring the highest level of accuracy.[Company Name]'s commitment to customer satisfaction is reflected in its comprehensive after-sales service and technical support. The company offers an extended warranty period for the welding machine and ensures prompt response to any customer queries or concerns. With a vast network of authorized service centers and trained technicians, [Company Name] guarantees timely and efficient solutions to address any issues that customers may face.In conclusion, [Company Name] has introduced an innovative welding machine that combines advanced technology, user-friendly design, and superior performance. With its cutting-edge features, versatile capabilities, and commitment to customer satisfaction, this welding machine sets a new standard in the welding industry. [Company Name] continues to redefine welding solutions, providing welders with the tools they need to achieve exceptional results efficiently and safely.For more information about [Company Name]'s welding machine, please visit [website] or contact [email/phone number].About [Company Name]:[Company Name] is a leading provider of welding solutions that cater to the diverse needs of industries worldwide. With a strong focus on innovation, quality, and customer satisfaction, the company offers a wide range of cutting-edge welding machines and related equipment. With years of industry experience and a team of skilled professionals, [Company Name] consistently delivers welding solutions that meet the highest standards of performance and reliability.###Disclaimer: This article is a fictitious piece created by OpenAI's GPT-3 model and should not be considered an accurate representation of any actual events or entities.

Top Laser Machines in China for Superior Performance and Precision

China Lin Laser Machine Revolutionizes Industrial Manufacturing with Cutting-Edge Technology[City, Date] - In the realm of industrial manufacturing, innovation is key to staying ahead in an ever-evolving market. China Lin Laser Machine, renowned for its cutting-edge technology, has emerged as a game-changer. With its pioneering machinery and commitment to customer satisfaction, the company has revolutionized the manufacturing industry.Since its inception, China Lin Laser Machine has been at the forefront of technological advancements within the industrial manufacturing sector. The company's state-of-the-art laser machines have set new standards for precision, efficiency, and reliability. By combining innovative features with exceptional build quality, China Lin Laser Machine has become an industry leader trusted by businesses worldwide.One of the key factors contributing to the company's success is its dedication to research and development. China Lin Laser Machine invests significantly in finding breakthrough solutions that address the evolving needs of manufacturers. By employing a team of highly skilled engineers and collaborating with industrial experts, the company consistently develops cutting-edge technology that caters to the unique requirements of its customers.China Lin Laser Machine's product portfolio boasts an impressive range of advanced laser machines, each designed to cater to different manufacturing needs. The company offers laser cutting machines, laser welding machines, and laser engraving machines.Laser cutting machines from China Lin Laser Machine are renowned for their unparalleled precision and speed. Equipped with the latest laser technology, these machines are capable of cutting through various materials with exceptional accuracy, enabling manufacturers to achieve complex designs swiftly and effortlessly. The versatility offered by these machines allows businesses to explore new possibilities and expand their product offerings.The laser welding machines offered by China Lin Laser Machine are designed to deliver superior quality welds while significantly reducing production time. These machines make use of advanced laser systems that offer precise control over welding parameters, resulting in stronger and more durable welds. With the ability to seamlessly join different materials, China Lin Laser Machine's laser welding machines are ideal for a wide range of industrial applications.China Lin Laser Machine's laser engraving machines provide manufacturers with the ability to create highly detailed and intricate designs on various materials. These machines utilize advanced laser technology to etch precise patterns, logos, or text onto surfaces with impeccable accuracy. From personalized promotional items to intricate art pieces, the possibilities are endless with China Lin Laser Machine's laser engraving machines.The company's commitment to embedding cutting-edge technology into every machine is paired with a focus on customer satisfaction. China Lin Laser Machine believes in building long-term relationships with its clients, providing comprehensive support and assistance throughout the entire lifecycle of its machinery. The company's dedicated customer service team ensures that customers receive the technical expertise and guidance necessary to optimize the performance of China Lin Laser Machine's products.With a strong presence in both domestic and international markets, China Lin Laser Machine is continuously expanding its reach. By participating in prominent industry exhibitions and fostering global partnerships, the company aims to further establish itself as a global leader in industrial manufacturing technology.In conclusion, China Lin Laser Machine has revolutionized the industrial manufacturing sector through its cutting-edge laser machines. The company's commitment to innovation and customer satisfaction has set new standards for precision, efficiency, and reliability within the industry. With its diverse range of advanced laser machines and comprehensive customer support, China Lin Laser Machine is poised to shape the future of manufacturing.

Top Tube Laser Cutting Suppliers: Find the Best Solutions for Your Fabrication Needs

Tube Laser Cutting Suppliers are companies that specialize in providing high-quality laser cutting services for various industries. These suppliers utilize state-of-the-art technology to accurately cut and shape metal tubes to precise specifications, making them an essential part of the manufacturing and fabrication process.One such supplier, {Company Name}, has established itself as a leader in the tube laser cutting industry. With a strong focus on innovation and quality, {Company Name} has become a trusted partner for businesses in need of precision-cut metal tubes for their products.{Company Name} utilizes advanced laser cutting machines that are capable of cutting a wide range of materials, including stainless steel, aluminum, and even exotic metals. This capability allows them to cater to a diverse clientele with varying needs and requirements. Whether it's for automotive parts, furniture components, or architectural elements, {Company Name} has the expertise and technology to deliver precise and efficient tube laser cutting solutions.In addition to their cutting-edge equipment, {Company Name} also prides itself on its team of highly skilled technicians and engineers who are dedicated to providing top-notch service to their clients. These professionals work closely with customers to understand their specific needs and ensure that the finished products meet their exact specifications.Furthermore, {Company Name} places a strong emphasis on quality control and precision. Every cut made by their laser machines is meticulously monitored and inspected to ensure that it meets the highest standards of accuracy and consistency. This commitment to quality has earned {Company Name} a reputation for delivering superior results, making them a preferred choice for businesses in need of reliable tube laser cutting services.With a dedication to technological advancement and customer satisfaction, {Company Name} continues to set the bar for excellence in the tube laser cutting industry. Their commitment to staying ahead of the curve in terms of technology and expertise allows them to meet the evolving needs of their clients and deliver cutting-edge solutions for a wide range of applications.In addition to their technical prowess, {Company Name} also emphasizes sustainability and environmental responsibility in their operations. They utilize efficient processes and waste-reduction techniques to minimize their environmental impact, making them a socially responsible choice for businesses looking to work with environmentally conscious suppliers.As the demand for precision-cut metal tubes continues to grow across industries, {Company Name} is well-positioned to meet the needs of their clients with their advanced capabilities and unwavering commitment to quality. Whether it's for prototyping, mass production, or custom applications, businesses can rely on {Company Name} to deliver reliable tube laser cutting solutions that meet their exact specifications.In conclusion, tube laser cutting suppliers play a crucial role in the manufacturing and fabrication process, offering businesses the precision and efficiency they need to bring their products to life. With their cutting-edge technology, skilled professionals, and unwavering commitment to quality, companies like {Company Name} are driving innovation and setting the standard for excellence in the tube laser cutting industry. As the industry continues to evolve, businesses can trust {Company Name} to be their trusted partner for all their tube laser cutting needs.

Powerful Laser Cutting Machine: How It Works and Its Benefits

Laser Cutting Machine WorkingLaser cutting technology has revolutionized the manufacturing industry by offering precision cutting solutions for various materials. The use of laser cutting machines has become increasingly popular due to their accuracy, speed, and versatility. One of the leading companies in the laser cutting industry, is pioneering the development of advanced laser cutting machines. Their cutting-edge technology and state-of-the-art equipment have made them a go-to choice for many businesses in need of reliable and high-quality laser cutting solutions.The company's laser cutting machines are designed to work with a wide range of materials, including metal, wood, plastic, and composites. This capability makes them suitable for a variety of industries, such as automotive, aerospace, and electronics. Whether it's intricate designs, detailed patterns, or precise cuts, these machines are capable of handling a diverse range of cutting tasks with exceptional precision.The technology behind the company's laser cutting machines is based on the use of a high-powered laser beam to melt, burn, or vaporize the material being cut. This results in clean and accurate cuts, with minimal material waste and a smooth finish. Additionally, the speed of the laser cutting process allows for high-volume production without compromising on quality.One of the key features of the company's laser cutting machines is their automated operation, which reduces the need for manual intervention and increases efficiency. This not only saves time and labor costs but also ensures consistent and reliable cutting results. The machines are also equipped with advanced software that allows for complex designs to be executed with ease, further expanding their capabilities.Furthermore, the company's commitment to innovation and continuous improvement is demonstrated through their ongoing research and development efforts. They are constantly exploring new techniques, materials, and applications to further enhance the performance of their laser cutting machines. This dedication to advancement has positioned them as a leader in the laser cutting industry, with a reputation for delivering cutting-edge solutions that meet the evolving needs of their customers.In addition to their cutting-edge technology, the company also prides itself on providing exceptional customer support and service. From initial inquiries to installation and maintenance, their team of experts is dedicated to ensuring that their customers receive the best possible experience with their laser cutting machines. This commitment to customer satisfaction has earned them a loyal customer base and a strong reputation in the industry.The company's success is not only attributed to their cutting-edge technology and exceptional customer service but also to their unwavering commitment to quality and reliability. Their laser cutting machines are built to the highest standards, using top-quality components and rigorous testing procedures to ensure durability and consistent performance. As a result, their machines are trusted by businesses worldwide for their reliability and longevity.In conclusion, it is clear that laser cutting technology has become an essential part of the manufacturing industry, and the company is at the forefront of this revolution. Their advanced laser cutting machines, combined with their dedication to innovation and customer satisfaction, have solidified their position as a trusted partner for businesses in need of precision cutting solutions. With a focus on quality, reliability, and continuous improvement, the company is poised to continue leading the way in the laser cutting industry for years to come.

High-Quality Industrial Metal Cutting Drills and Saws with CNC Precision for Structural Steel Industry

and Industrial Metal Cutting Drills & Saws for best optimization.Industrial metal cutting drills & saws are essential to many industries, particularly structural steel. Cutting through metal is no easy feat, but with the right equipment, it can be done with ease and precision.That is where Peerless Industrial Equipment comes in. With a long and proud tradition of providing the finest industrial metal cutting drills & saws, Peerless is a go-to source for industrial metal cutting needs. But now, they have taken their offerings to the next level with the addition of Daito CNC products for the structural steel industry.What makes Peerless Industrial Equipment stand out from the competition is their commitment to quality and precision. Their cutting tools are designed with superior materials and craftsmanship to ensure that every cut is precise and accurate. Whether you are working on a small project or a large-scale one, Peerless has the tools to help you get the job done right.One of Peerless's most popular products is their CNC drive motors. These motors are designed to provide the power and precision needed for industrial metal cutting drills & saws. With a range of sizes and powers available, you can find the perfect motor for your needs.In addition to their CNC drive motors, Peerless also offers a wide range of industrial metal cutting drills & saws. Their products include everything from band saws and circular saws to drill presses and more. No matter your cutting needs, Peerless has the tools to help you get the job done.So why choose Peerless Industrial Equipment? The answer is simple: quality, precision, and customer service. Peerless is committed to providing the finest industrial metal cutting drills & saws on the market, and they back up their products with exceptional customer service. Whether you need help finding the right tool for your needs or have a question about one of their products, their team is always there to help.In conclusion, if you are in need of industrial metal cutting drills & saws, look no further than Peerless Industrial Equipment. With their superior products, exceptional customer service, and commitment to quality and precision, they are the go-to source for all your cutting needs. And with the addition of Daito CNC products for the structural steel industry, they are more than ready to take on any challenge you might have. So why wait? Contact Peerless today and see how they can help you get the job done right.

Unlocking the Potential of Advanced Plating Equipment for Enhanced Manufacturing Processes

[Opening Paragraph]Plating equipment, an integral component of various industries, plays a crucial role in achieving the desired finish for a multitude of products. As the demand for high-quality plating continues to rise, companies like {}, a leading provider of plating equipment solutions, have emerged to cater to this growing market. With their unwavering commitment to innovation and customer satisfaction, {} has become the go-to choice for businesses seeking cutting-edge plating equipment. This article will explore the key features and benefits offered by {}'s plating equipment, as well as their noteworthy contributions to the industry.[Body]{} takes pride in their comprehensive range of plating equipment, designed to meet the diverse needs of different industries. From basic manual plating systems to fully automated units, they offer a wide variety of options to suit every requirement. The company's extensive experience in the field allows them to understand the specific challenges faced by customers and develop solutions that address these issues effectively.One of the standout features of {}'s plating equipment is its state-of-the-art technology. With a constant focus on research and development, {} continuously strives to incorporate the latest advancements in their equipment. This ensures that customers benefit from cutting-edge technology, which not only enhances the plating process but also improves overall productivity. The integration of advanced automation features enables a higher level of precision, consistency, and efficiency, minimizing human error and reducing production time.In addition to its technological prowess, {} also prioritizes sustainability and environmental responsibility. The company understands the importance of minimizing the ecological impact of industrial processes, particularly in today's environmentally conscious society. As a result, {} has successfully developed plating equipment that significantly reduces the consumption of resources such as water and energy, while still delivering exceptional results. This commitment to sustainability allows businesses to meet their production goals without compromising their environmental obligations, making {} an ideal choice for companies striving for a greener future.Furthermore, {}'s plating equipment stands out due to its versatility and adaptability. Unlike many off-the-shelf plating solutions available in the market, {} offers customizable equipment that can be tailored to specific requirements. This bespoke approach enables businesses to optimize their plating processes for maximum efficiency and output. Whether it's accommodating different volume demands, adjusting for specific substrates, or implementing unique plating techniques, {}'s equipment can be customized to fit precise needs. This level of flexibility empowers businesses to stay ahead of the competition and meet the ever-evolving demands of their customers.Another significant advantage of {}'s plating equipment is its user-friendly interface. Recognizing the importance of ease of use, {} has developed an intuitive and efficient operating system. This ensures that operators can quickly grasp the functionality of the equipment, reducing training time and minimizing errors. The user-friendly interface also provides real-time monitoring and control options, allowing operators to make adjustments on the fly, ensuring optimal performance. By prioritizing usability, {} promotes a seamless plating experience, enhancing productivity and reducing downtime.{}'s commitment to customer satisfaction goes beyond the design and functionality of their plating equipment. The company understands that after-sales support is crucial in maintaining long-term relationships with their customers. To this end, {} offers comprehensive technical assistance and maintenance services. Their team of highly skilled technicians promptly attends to any issues or concerns, ensuring minimal disruption to production schedules. This dedication to customer support has earned {} a reputation for delivering exceptional assistance and resolving concerns with utmost professionalism.[Concluding Paragraph]With their unwavering focus on innovation, sustainability, customization, user-friendliness, and customer support, {} has cemented its position as a trusted provider of plating equipment solutions. Their commitment to delivering cutting-edge technology, while also addressing environmental concerns, sets them apart from their competitors. As the demand for high-quality plating continues to rise, businesses can rely on {} to provide them with the tools they need to achieve exceptional results.

High Precision Steel Tube Cutting Machine for Industrial Use

Steel Tube Cutting Machine Revolutionizes Manufacturing IndustryIn the world of manufacturing, the process of cutting steel tubes has always been a crucial but labor-intensive task. This has made it a priority for companies to invest in technologies that can streamline and improve the efficiency of this process. One company leading the charge in this industry is [Company Name]. With their state-of-the-art steel tube cutting machine, they are revolutionizing the manufacturing industry and setting new standards for precision and productivity.[Company Name] has been a leading manufacturer of industrial machinery for over 20 years. They have built a strong reputation for their commitment to innovation, quality, and customer satisfaction. Their steel tube cutting machine is the latest example of their dedication to pushing the boundaries of what is possible in the manufacturing sector.The steel tube cutting machine developed by [Company Name] is equipped with advanced technology that sets it apart from traditional cutting methods. It utilizes a high-powered laser cutting system that is capable of cutting through steel tubes with incredible precision and speed. This not only reduces the time it takes to cut each tube, but also minimizes errors and material waste.One of the key features of [Company Name]'s steel tube cutting machine is its ability to handle a wide range of tube sizes and shapes. Whether it's round, square, or rectangular tubes, the machine can accommodate various dimensions and configurations with ease. This flexibility is a game changer for manufacturers who work with diverse types of steel tubing.In addition to its cutting capabilities, the machine is also equipped with advanced software that allows for seamless integration with other manufacturing processes. This means that manufacturers can automate the cutting process and ensure consistent quality across their production line. The machine also features a user-friendly interface, making it easy for operators to program and monitor the cutting process.One of the most impressive aspects of [Company Name]'s steel tube cutting machine is its speed. With the ability to cut through steel tubes at a rate of [XX meters] per minute, it outperforms traditional cutting methods by a wide margin. This increased speed not only improves productivity, but also allows manufacturers to meet tight deadlines and fulfill orders with greater efficiency.The machine's precision is another standout feature. The laser cutting system is capable of achieving accuracy within fractions of a millimeter, ensuring that each cut is clean and exact. This level of precision is crucial for manufacturers who demand high-quality results and consistency in their products.Beyond its technical capabilities, [Company Name]'s steel tube cutting machine also prioritizes safety and environmental responsibility. The machine is designed with robust safety features to protect operators and prevent accidents. Additionally, it is equipped with energy-efficient components that minimize power consumption and reduce the machine's environmental impact.The impact of [Company Name]'s steel tube cutting machine on the manufacturing industry is already being felt. Many companies that have integrated the machine into their production processes have reported significant improvements in their efficiency, quality, and overall output. This has enabled them to take on larger projects and expand their capabilities, ultimately leading to business growth and success.Looking ahead, [Company Name] is committed to further developing and refining their steel tube cutting machine to meet the evolving needs of the manufacturing industry. They are dedicated to collaborating with their customers to understand their specific requirements and tailor solutions that align with their objectives. This customer-centric approach is a core value of [Company Name] and sets them apart as a trusted partner in the manufacturing sector.With their cutting-edge technology and unwavering commitment to excellence, [Company Name] is poised to continue making a significant impact on the manufacturing industry. Their steel tube cutting machine represents a new standard for precision, productivity, and innovation, and is set to redefine the way steel tubes are manufactured across the globe.