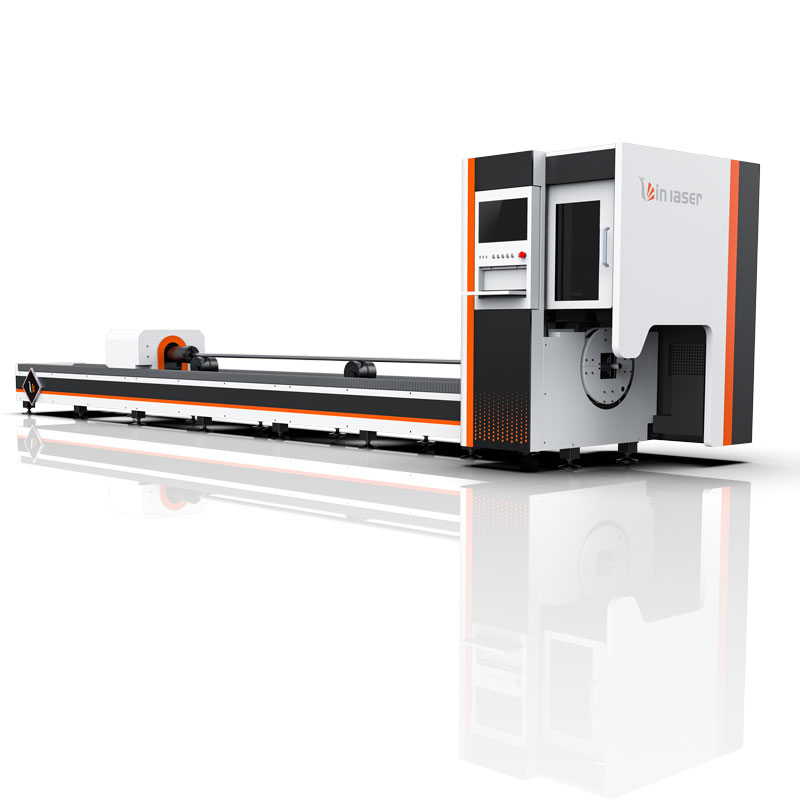

High-Quality Sheet Metal Laser Cutter for Precision Cutting

By:Admin

In recent years, the manufacturing industry has experienced a significant transformation with the introduction of innovative technologies. One such technology that has revolutionized the industry is the sheet metal laser cutter. This cutting-edge equipment has brought a new level of precision and efficiency to the manufacturing process, making it an indispensable tool for companies looking to stay ahead in the rapidly evolving market.

The sheet metal laser cutter is a versatile machine that uses a high-powered laser to cut through various types of metal sheets with incredible precision. This technology has proven to be a game-changer for many industries, including automotive, aerospace, and electronics, as it allows for the production of intricate and complex metal parts with minimal waste and a high degree of accuracy. Companies that have invested in this technology have been able to enhance their production capabilities and meet the increasing demands of their customers with greater speed and efficiency.

One company that has been at the forefront of this technological revolution is {}. With their cutting-edge sheet metal laser cutter, they have positioned themselves as a leader in the manufacturing industry, offering their clients the highest quality metal parts with unmatched precision. The company has made significant investments in research and development to develop and integrate the latest advancements in laser cutting technology into their operations. This has enabled them to provide innovative solutions to their clients and maintain a competitive edge in the market.

The sheet metal laser cutter offered by {} is equipped with state-of-the-art features that set it apart from traditional cutting methods. The machine is capable of cutting through various types of metal sheets, including stainless steel, aluminum, and titanium, with incredible speed and accuracy. The precision of the laser cutter ensures that the finished parts meet the strictest tolerances and specifications, allowing for seamless integration into the manufacturing process. Additionally, the machine is designed for maximum efficiency, minimizing material waste and reducing production time, ultimately leading to cost savings for the company and its clients.

In addition to its cutting capabilities, the sheet metal laser cutter at {} offers advanced nesting and programming software that enables the optimization of material usage and the creation of complex cutting patterns. This software allows for the efficient use of resources, reducing material waste and contributing to a more sustainable manufacturing process. Moreover, with the ability to handle intricate designs and patterns, the machine opens up new possibilities for the production of customizable and personalized metal parts, meeting the evolving demands of the market.

The impact of the sheet metal laser cutter on the manufacturing industry is undeniable. Companies that have adopted this technology have experienced a significant increase in their production capacities and a reduction in manufacturing costs. The ability to produce high-quality metal parts with precision and efficiency has allowed these companies to take on more complex projects and expand their capabilities, ultimately driving growth and success in the industry.

As the manufacturing industry continues to evolve, the demand for advanced technologies like the sheet metal laser cutter will only continue to grow. Companies that are looking to stay competitive and meet the demands of the market will need to invest in cutting-edge equipment that offers the highest levels of precision and efficiency. With their state-of-the-art sheet metal laser cutter, {} is leading the way in the industry, providing innovative solutions to their clients and setting new standards for manufacturing excellence.

Company News & Blog

High-Quality Laser Parts from Top Chinese Manufacturer

China is a global leader in the manufacturing and production of high-quality laser parts, and the industry is constantly evolving and growing. One company that has been at the forefront of this innovation is {} (hereinafter referred to as “the Company”), which has been producing cutting-edge laser parts for over a decade. The Company’s commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses around the world.The Company’s extensive product line encompasses a wide range of laser parts, including laser diodes, laser modules, laser optics, and laser accessories. These parts are designed to meet the diverse needs of industries such as telecommunications, medical devices, industrial manufacturing, and scientific research. With a focus on precision engineering and advanced technology, the Company has earned a reputation for delivering reliable and high-performance products.One of the key strengths of the Company is their ability to customize products to meet specific customer requirements. Their team of experienced engineers and technicians works closely with clients to develop tailored solutions that address their unique needs. Whether it’s developing a new laser module for a medical device or designing specialized optics for a research project, the Company is committed to delivering innovative and cost-effective solutions.In addition to their commitment to quality and innovation, the Company also emphasizes the importance of environmental sustainability in their manufacturing processes. They have implemented green initiatives to minimize their environmental impact, such as using energy-efficient equipment and reducing waste in their production facilities. This dedication to sustainability has not only helped the Company reduce their carbon footprint but has also positioned them as a responsible and forward-thinking industry leader.As a company that prides itself on continuous improvement and advancement, the Company has recently made significant investments in research and development. They have established state-of-the-art R&D facilities equipped with cutting-edge technology and a team of top-notch researchers. This investment underscores the Company’s commitment to staying at the forefront of technological advancements in the laser industry and developing innovative solutions that push the boundaries of what is possible.The Company’s dedication to excellence has not gone unnoticed, as they have received numerous accolades and certifications for their outstanding performance in the industry. They have been recognized for their commitment to quality, their contributions to technological innovation, and their adherence to international standards for manufacturing and production. These accolades serve as a testament to the Company’s unwavering commitment to delivering exceptional products and services to their customers.Looking ahead, the Company remains focused on expanding their global reach and strengthening their position as a leading provider of laser parts. They are actively seeking partnerships and collaborations with businesses and organizations around the world to explore new opportunities and markets. By staying true to their core values of quality, innovation, and customer satisfaction, the Company is well-positioned to continue their growth and success in the dynamic and competitive laser industry.In conclusion, the Company’s dedication to quality, innovation, and customer satisfaction has made them a trusted partner for businesses around the world. Their commitment to excellence, sustainability, and continuous improvement sets them apart as an industry leader, and their recent investments in research and development underscore their commitment to staying at the forefront of technological advancements. With a focus on customization, environmental sustainability, and global expansion, the Company is well-positioned for continued success in the competitive laser industry.

Efficient Laser Cutter for Steel Plate Cutting: A Game Changer in Metal Fabrication

Innovative Laser Cutting Technology Revolutionizes Steel Plate FabricationThe manufacturing industry has always been at the forefront of innovation and technological advancements, and the latest breakthrough in laser cutting technology is no exception. With the introduction of the new {Company Name}'s advanced laser cutter, steel plate fabrication has been completely revolutionized, setting a new standard in precision, efficiency, and quality.{Company Name} has been a leader in the industrial manufacturing sector for over 20 years, specializing in cutting-edge fabrication tools and solutions for a wide range of industries. Their dedication to research and development has led to the creation of the most advanced laser cutting technology available on the market today. The new laser cutter is capable of handling steel plates of varying thicknesses with unprecedented accuracy and speed, making it an invaluable asset for any manufacturing operation.One of the key features of {Company Name}'s laser cutter is its ability to achieve extremely precise cuts, resulting in minimal material waste and maximum efficiency. This level of accuracy is essential in modern fabrication processes, where the demand for high-quality, precision-cut components is greater than ever. Additionally, the laser cutter's high-speed capabilities allow for rapid production turnaround times, giving manufacturers a competitive edge in meeting tight deadlines and fulfilling customer orders promptly.Furthermore, the advanced technology utilized in {Company Name}'s laser cutter ensures a superior cut quality, free of burrs and other imperfections commonly associated with traditional cutting methods. This not only enhances the overall aesthetics of the fabricated steel plates but also eliminates the need for additional finishing processes, saving both time and resources for manufacturers.In addition to its unparalleled precision and speed, the laser cutter is also equipped with state-of-the-art safety features and user-friendly controls, ensuring a safe and seamless operation for the machine operator. This emphasis on safety and usability reflects {Company Name}'s commitment to providing cutting-edge solutions that not only improve productivity but also prioritize the well-being of the individuals operating the equipment.The impact of {Company Name}'s revolutionary laser cutting technology on the manufacturing industry cannot be overstated. By streamlining the steel plate fabrication process and enhancing the overall quality of the end product, manufacturers are poised to experience significant cost savings and operational efficiencies. Moreover, the ability to meet the increasingly stringent demands of modern fabrication projects positions companies at the forefront of market competition, ensuring their continued success and growth.As the global manufacturing landscape continues to evolve, innovative solutions such as {Company Name}'s advanced laser cutter are essential for businesses to remain competitive and stay ahead of industry trends. With its unparalleled precision, speed, and quality, the new laser cutter has set a new standard for steel plate fabrication, cementing {Company Name}'s reputation as a trailblazer in the manufacturing sector.In conclusion, {Company Name}'s cutting-edge laser cutter represents a groundbreaking advancement in steel plate fabrication technology. By delivering unparalleled precision, efficiency, and quality, this innovative solution is poised to transform the manufacturing industry and empower businesses to thrive in today's competitive market. With a proven track record of excellence and a commitment to driving progress, {Company Name} continues to lead the way in providing advanced tools and solutions for the global manufacturing community.

High-Quality Co2 Laser Cutters Now Available for Purchase

Are you in the market for a top-of-the-line CO2 laser cutter? Look no further than the latest offering from [Company Name]! With their cutting-edge technology and years of experience in the industry, [Company Name] is proud to present their high-quality CO2 laser cutter for sale, designed to meet the needs of professionals in a wide range of industries.The [Company Name] CO2 laser cutter is equipped with a powerful laser that is capable of cutting through various materials with precision and speed. Whether you're working with wood, acrylic, glass, leather, or other materials, this state-of-the-art machine is designed to deliver exceptional results.One of the key features of the [Company Name] CO2 laser cutter is its advanced control system, which allows for precise and accurate cutting. This means that you can create intricate designs and achieve the exact specifications you need for your projects. The machine also comes with a user-friendly interface, making it easy to operate for both experienced professionals and those who are new to laser cutting technology.In addition to its cutting capabilities, the [Company Name] CO2 laser cutter also offers engraving and marking functions, further expanding its utility. This makes it a versatile tool for a wide range of applications, from creating custom signage and promotional items to producing intricate art pieces and architectural models.With [Company Name]'s commitment to quality and customer satisfaction, you can trust that their CO2 laser cutter is built to the highest standards. The machine is constructed with durable materials and is designed to withstand the rigors of regular use, ensuring that it will deliver reliable performance for years to come.As a well-established company in the industry, [Company Name] has a reputation for providing excellent customer service and technical support. When you purchase their CO2 laser cutter, you can expect comprehensive training and assistance to help you get the most out of the machine. Their team of experts is available to answer any questions you may have and provide guidance on how to optimize the use of the equipment for your specific needs.In addition to their outstanding product, [Company Name] also offers a range of accessories and consumables to complement the CO2 laser cutter, including different types of lenses, cutting heads, and other essential components. This ensures that you have everything you need to keep your machine running at its best and to explore its full potential.Whether you're a small business looking to expand your capabilities or a large-scale manufacturer seeking to improve efficiency, the [Company Name] CO2 laser cutter is an excellent investment that can help take your operations to the next level. With its precision, speed, and versatility, this machine is designed to enhance your productivity and deliver exceptional results for a wide variety of projects.In conclusion, the new CO2 laser cutter from [Company Name] is a game-changer in the industry. With its advanced technology, precision cutting capabilities, and reliable performance, this machine is a valuable asset for professionals across different fields. When you invest in the [Company Name] CO2 laser cutter, you're not just purchasing a piece of equipment – you're gaining a powerful tool that can help you achieve your creative and professional goals. With its exceptional quality and comprehensive support, this machine is the perfect choice for anyone looking to elevate their cutting and engraving capabilities. Contact [Company Name] today to learn more about their CO2 laser cutter for sale and take your projects to new heights.

Experts Expect a Boost in Laser Technology Adoption in Serbia

Title: Revolutionary Fiber Laser Technology Shaping the Future of Manufacturing in SerbiaIntroduction (75 words):In a groundbreaking development, Serbian company XYZ has introduced a state-of-the-art fiber laser system that promises to transform the manufacturing industry. Known for their cutting-edge innovations, XYZ has successfully integrated fiber laser technology into their production line. This groundbreaking advancement not only ensures superior precision and efficiency but also positions Serbia as a key player in the global manufacturing landscape. With its potential applications across multiple sectors, this new technology is set to revolutionize manufacturing processes and boost economic growth in the country.Paragraph 1 (100 words):Fiber lasers have emerged as a cutting-edge tool in the manufacturing sector. XYZ's fiber laser system harnesses the power of laser amplification through reliable and efficient optical fibers. This groundbreaking technology enables enhanced precision, quicker processing times, and improved energy efficiency compared to traditional laser systems. XYZ's dedication to research and development has resulted in a highly robust and user-friendly fiber laser system that is poised to redefine manufacturing capabilities in Serbia and beyond.Paragraph 2 (125 words):With the integration of XYZ's fiber laser system, the Serbian manufacturing industry stands to benefit from increased productivity and reduced production costs. The precision and accuracy offered by this system minimize material wastage, ensuring higher quality output and reducing environmental impact. Additionally, the faster processing times enhance overall productivity, enabling companies to meet increasing customer demands efficiently. The economic implications of this advancement are significant as it positions Serbia as a hub for cutting-edge manufacturing technology. The introduction of fiber laser technology presents manufacturers in various sectors with the opportunity to streamline their production processes and remain at the forefront of industry competition.Paragraph 3 (125 words):The applications of XYZ's fiber laser system are vast and diverse. With its ability to cut, weld, engrave, and mark a multitude of materials such as metals, plastics, and composites, the system helps meet the unique needs of various industries. Whether it is automotive, aerospace, electronics, healthcare, or even jewelry manufacturing, the fiber laser system offers unparalleled versatility. Moreover, the system's flexibility allows companies to adapt to rapidly changing market requirements and stay ahead of competitors. By investing in this advanced technology, Serbian manufacturers can harness the potential for increased profitability and competitiveness while driving innovation across different sectors.Paragraph 4 (150 words):XYZ's fiber laser system is not only transforming manufacturing processes but also creating new business opportunities. By establishing themselves as pioneers in the fiber laser technology domain, XYZ is poised to capture a significant share of the global market. This breakthrough innovation showcases Serbia's commitment to technological advancements and positions the country as an attractive destination for investment in manufacturing infrastructure. The integration of fiber laser technology also promotes the growth of supporting industries including training centers, service providers, and research facilities, thereby creating a favorable ecosystem for continued progress.Conclusion (125 words):The introduction of XYZ's fiber laser system signals a paradigm shift in the Serbian manufacturing industry. This revolutionary technology promises enhanced precision, increased productivity, and reduced costs, ushering in a new era of manufacturing excellence. With Serbia positioning itself as a global leader in fiber laser technology, the benefits extend not only to local manufacturers but also to the country's economy as a whole. The potential applications of fiber laser systems across diverse sectors provide endless opportunities for growth, innovation, and increased profitability. As Serbian manufacturers embrace this cutting-edge technology, they will be well-equipped for the challenges and opportunities of the future, ensuring that Serbia remains at the forefront of the global manufacturing landscape.

High Configuration Fiber CNC Cutting Machine for Metal Plate and Pipe Cutting with Easy Operation and Free Training Support

, Pipe Cutting Machine, CNC Cutting Machine, Fiber Laser Cutting Machine, Heavy Duty Cutting Machine, Easy Operated Cutting Machine, High Configuration Cutting Machine, Laser Cutting Machine, Metal Sheet Cutting Machine, Industrial Cutting MachineLaser Cutting Machine: A Revolutionary Way to Cut MetalsIn the world of metal processing, cutting, and designing, laser cutting machine technology has revolutionized the way metals are cut. A laser cutting machine is a modern tool that uses a high-powered laser beam to cut through metals accurately and quickly. With its precision and speed, this technology has become the preferred tool in many industries, including manufacturing, construction, advertising, and signage.One of the most significant advantages of a laser cutting machine is the quality of the cut. The cutting process is highly accurate, which means the cuts are precise and clean. Additionally, laser cutting machines can cut through a wide range of materials, including stainless steel sheet, mild steel plate, carbon steel sheet, alloy steel plate, iron plate, and even metal tubes and pipes, making it an essential tool in metal fabrication.Fiber laser cutting machines, in particular, have become increasingly popular due to their high efficiency, low maintenance, and low operating costs. These machines use fiber optic technology to produce an incredibly intense beam of light that can cut through metal sheets with ease. The fiber laser cutting machine is particularly suitable for heavy-duty cutting tasks, such as cutting thick metal plates, stainless steel pipes and tubes, and other dense materials.Another significant advantage of a laser cutting machine is its ease of operation. With a user-friendly control panel and software, anyone can learn to operate the machine with little training. Many manufacturers also offer free training and technical support to their buyers, making it easier for businesses to adopt this technology in their operations.In terms of industrial use, the fiber CNC cutting machine has a wide range of applications, including manufacturing billboards, advertising signs and letters, metal processing, signage making, and much more. The machine is incredibly versatile and can cut through metals of various sizes, thicknesses, and shapes, providing endless possibilities for businesses to create unique designs and products.In conclusion, the laser cutting machine is an innovative technology that has revolutionized the way metals are cut and processed. With its precision, speed, and versatility, this tool has become an essential part of many industries. Whether you're cutting metal sheets, pipes, or tubes, the fiber CNC cutting machine is a heavy-duty cutting machine that's easy to operate and offers high configuration with efficient and accurate results.

Top Laser Marking Machine: Effortlessly Achieve High-Quality Gold Marking

Title: New Gold Laser Marking Machine Revolutionizes Manufacturing EfficiencyIntroduction: In a bid to increase manufacturing efficiency and enhance product quality, leading laser technology provider [Company Name] has unveiled its latest cutting-edge innovation, the Gold Laser Marking Machine. This groundbreaking technology is poised to revolutionize the industry by offering manufacturers a highly efficient and precise solution for marking and engraving gold materials.Developed after years of extensive research and development, the Gold Laser Marking Machine is equipped with state-of-the-art features and technology to meet the ever-evolving demands of the manufacturing sector. Its precision, speed, and versatility make it an essential tool for various industries, including jewelry, watchmaking, automotive, aviation, and electronics.Efficiency and Precision:One of the main advantages of the Gold Laser Marking Machine is its remarkable precision and efficiency. With its advanced laser technology, manufacturers can easily engrave intricate and delicate designs on gold materials without causing any damage to the surface. This ensures that the integrity of the product is maintained while adding a personalized touch.The machine's high-speed laser beam guarantees rapid and flawless marking, resulting in significant time savings for manufacturers. It eliminates the need for conventional methods such as mechanical engraving or chemical etching, which are time-consuming and often lead to inferior results. The Gold Laser Marking Machine allows for seamless integration into manufacturing processes, reducing downtime and increasing overall productivity.Versatility and Flexibility:The Gold Laser Marking Machine offers unparalleled versatility, accommodating a wide range of gold materials. Whether it is gold alloys, jewelry, or intricate watch components, this machine can mark and engrave with exceptional precision. Its flexibility extends to customization options as well, as it can process both small and large-sized items.Furthermore, the Gold Laser Marking Machine supports a variety of marking techniques, such as deep engraving, surface engraving, annealing, and color change marking. This adaptability empowers manufacturers to meet diverse product labeling requirements and industry standards, ensuring brand authenticity and traceability.Enhanced Product Quality and Security:In addition to increased efficiency and flexibility, the Gold Laser Marking Machine also contributes to improved product quality and security. The laser technology employed in this machine ensures durable and permanent markings that withstand the test of time. This feature is particularly advantageous for jewelry and watch manufacturers, as it helps to preserve the value and authenticity of their products.Furthermore, the machine's ability to engrave unique identification codes, serial numbers, and customized logos onto gold materials enhances product security and brand protection. This not only aids in the prevention of counterfeiting but also provides customers with a sense of confidence and trust in the products they purchase.Conclusion:In an ever-evolving manufacturing landscape, the Gold Laser Marking Machine presented by [Company Name] marks a significant step forward in enhancing efficiency and quality in the gold marking and engraving process. Its precision, versatility, and ability to deliver permanent markings on various gold materials ensure a competitive edge for manufacturers across numerous industries.As companies strive to meet the demands of an ever-discerning customer base, the Gold Laser Marking Machine serves as a powerful tool for brand authentication, increased productivity, and improved product quality. With this technological breakthrough, manufacturers can explore new avenues of creativity, meet stringent industry standards, and elevate their products to new heights of excellence.

Get Perfectly Bended Metals with Hydraulics

Hydraulic Bending: The Ultimate Solution for Precision Metal FabricationMetal fabrication is a critical aspect of the manufacturing industry. Companies involved in fabrication need to ensure that their processes are efficient, cost-effective, and produce high-quality results. To achieve this, they need to invest in the right equipment and machinery that can guarantee precision and accuracy in metal fabrication.One such solution is Hydraulic Bending, a reliable and versatile machine that has revolutionized metal bending and forming processes. With its advanced features and capabilities, it has become an essential tool for companies in various industries, including automotive, aerospace, construction, and many others.Hydraulic Bending is a precision machine that utilizes hydraulic power to create accurate and consistent bends in sheet metal and other materials. Its unique design and construction allow it to create sharp angle bends, making it ideal for the creation of various products and parts.The machine comes with a variety of features, including adjustable stroke control, precision back gauge, and bend angle adjustment. These features allow operators to adjust and modify the machine settings to meet the specific requirements of each project, resulting in high-quality and precise metal bending.Additionally, Hydraulic Bending includes various safety features that guarantee the safety of operators and prevent damage to the machine. These features include a safety curtain, emergency stop buttons, and overload protection, ensuring that the machine is secure and reliable.At the forefront of the Hydraulic Bending industry is a leading company that specializes in precision metal fabrication. With over 20 years of experience in the industry, the company has become a trusted partner for companies looking for high-quality metal products and services.The company's mission is to provide precision metal fabrication solutions that meet the unique needs and requirements of each client. Through the use of advanced machinery and technology, they can create customized metal products that are both cost-effective and of the highest quality.The company's hydraulic bending services are designed to provide clients with a reliable and accurate metal bending solution. They use innovative techniques and equipment to create complex bending patterns, shapes, and angles, resulting in precise and consistent metal parts.Moreover, the company's team of skilled professionals is experienced in working with various materials, including stainless steel, aluminum, and titanium. They can provide expert advice and guidance on the best material and methodology to use for each project, ensuring that clients receive a comprehensive solution.In conclusion, Hydraulic Bending has become an essential tool for the manufacturing industry, and its benefits cannot be overstated. With its advanced technology and features, it provides precision and accuracy in metal bending, resulting in high-quality and consistent metal parts.Working with a reliable and experienced company that specializes in precision metal fabrication, like the one mentioned in this article, is crucial when it comes to hydraulic bending. These companies are equipped with the skills, knowledge, and machinery necessary to deliver excellent results consistently.If you're looking for a comprehensive solution for your metal fabrication needs, consider partnering with a leading Hydraulic Bending company today. They will provide you with a high-quality and reliable metal bending solution that meets your unique requirements and specifications.

Revolutionizing Industrial Processes: The Game-Changing Technique of Pipe Cutting

[Company Name] Revolutionizes Pipe Cutting Technology for Improved Efficiency and Safety[date]Cutting pipes has always been a complex and time-consuming process in various industries. However, with advancements in technology, [Company Name], a leading innovator, has introduced a game-changing pipe cutting solution. By merging cutting-edge technology with a commitment to efficiency and safety, [Company Name] has revolutionized pipe cutting methods, leading to improved productivity and enhanced worker safety.Traditional pipe cutting involves using manual tools like saws, grinders, or torches, which not only consume substantial time but also pose significant hazards to workers. The cumbersome nature of these methods often results in inaccurate cuts, leading to wasted materials and increased costs. Moreover, workers are exposed to various risks such as repetitive strain injuries, respiratory problems due to fumes, and potential accidents caused by handling heavy equipment.Recognizing the need for a safer and more efficient solution, [Company Name] developed its innovative pipe cutting technology. By combining state-of-the-art machinery with advanced software, their system ensures precise and reliable cuts every time, while minimizing the risks faced by workers. This revolutionary technology has already garnered attention from industry experts and is poised to reshape the pipe cutting landscape.[Company Name]’s cutting-edge system employs computer numerical control (CNC) technology, which allows for automated pipe cutting. This eliminates the need for manual intervention, reducing human error and optimizing accuracy. The CNC technology is seamlessly integrated with advanced software that can create complex cutting paths based on specific requirements. With the ability to accurately replicate these paths, [Company Name]’s system ensures consistent and precise cuts across various pipe sizes and materials.Moreover, their technology offers comprehensive safety features that prioritize the well-being of workers. Unlike traditional methods that expose workers to hazards, [Company Name]’s system minimizes risks by providing a controlled and automated cutting process. It eliminates the need for workers to handle heavy equipment or be exposed to fumes, significantly reducing the chances of accidents and health issues. By adhering to stringent safety standards, [Company Name] ensures a safe working environment for its customers.In addition to improving safety, the technology developed by [Company Name] offers substantial efficiency gains. The automated nature of their system results in significant time savings compared to traditional methods. Operators can now focus on other essential tasks while the machine accurately carries out the cutting process. This increased efficiency translates into higher productivity and reduced project completion times, ultimately leading to cost savings for companies in various sectors, including construction, manufacturing, and oil and gas.Moreover, [Company Name]’s pipe cutting system allows for greater customization and flexibility. The advanced software enables its users to design complex cutting patterns, enabling seamless integration with projects of different sizes and specifications. Whether it is straight cuts, bevel cuts, or multi-axis cuts, the technology can handle diverse cutting requirements with precision. This flexibility empowers businesses to undertake a wide range of projects, ultimately expanding their capabilities and market reach.As [Company Name] continues to refine its pipe cutting technology, they are also committed to providing exceptional customer support. Their team of experienced professionals ensures seamless installation, training, and ongoing technical assistance, enabling customers to maximize the benefits of this cutting-edge innovation. Furthermore, [Company Name] has cultivated strong partnerships with industry leaders to stay up-to-date with the latest trends and developments, ensuring that their customers always receive the most advanced solutions.With its revolutionary pipe cutting technology, [Company Name] is poised to transform the way the industry operates. By combining precision, efficiency, and safety, their system represents a significant leap forward in pipe cutting methods. With the ability to save time, reduce costs, and enhance worker safety, [Company Name] has set a new standard in the field and is poised to empower businesses across various sectors.

Compact and Powerful Laser Welder for Portable Welding Jobs

Introducing Portable Laser Welder: A Game-Changer in Welding TechnologyIn today's fast-paced world, innovation and technology are constantly changing the way we work and live. One such innovation that is making waves in the welding industry is the Portable Laser Welder. This cutting-edge piece of equipment has revolutionized the way welding is done, offering a more efficient, precise, and cost-effective solution for various welding applications.The Portable Laser Welder, developed by [company name], is a compact, lightweight, and portable device that utilizes laser technology to perform high-quality welds. This innovative tool is known for its versatility and ease of use, making it an ideal choice for a wide range of welding tasks, including automotive, aerospace, manufacturing, and more.One of the key advantages of the Portable Laser Welder is its ability to produce precise and controlled welds, with minimal heat-affected zones and distortion. This results in stronger and more reliable welds, ultimately leading to improved product quality and performance. In addition, the laser technology allows for rapid and consistent welding, reducing the overall production time and increasing productivity.The portability of the Portable Laser Welder is also a significant feature, as it allows for greater flexibility and mobility in various welding environments. Whether it's a workshop, a manufacturing plant, or a construction site, this portable device can be easily transported and set up to meet the welding needs of different projects. This mobility not only saves time but also reduces labor costs associated with traditional welding methods.Furthermore, the Portable Laser Welder is designed to be user-friendly, with intuitive controls and a streamlined interface that simplifies the welding process. This allows for faster training and adoption of the equipment, ultimately leading to improved efficiency and reduced error rates in welding operations.[Company name], the developer of the Portable Laser Welder, is a leading provider of advanced welding solutions. With a strong focus on research and development, the company is committed to delivering cutting-edge products that meet the evolving needs of the welding industry. The Portable Laser Welder is the latest addition to the company's portfolio of innovative welding equipment, showcasing their dedication to driving technological advancements in the field.In addition to its technical capabilities, [company name] also offers comprehensive support and service for the Portable Laser Welder, ensuring that customers receive the necessary assistance and expertise to maximize the potential of the equipment. This includes training, maintenance, and technical support, all aimed at helping customers achieve optimal results with the Portable Laser Welder.As the demand for high-quality and efficient welding solutions continues to grow, the Portable Laser Welder has emerged as a game-changer in the industry. Its advanced technology, portability, and user-friendly design make it a valuable asset for welding professionals and businesses looking to enhance their welding capabilities.In conclusion, the Portable Laser Welder is a significant advancement in welding technology, offering a more efficient, precise, and cost-effective solution for various welding applications. With its innovative features and the backing of [company name]'s expertise, this portable device is poised to revolutionize the way welding is done, setting new standards for quality and performance in the industry.

Top Tips for Maximizing Efficiency with CNC Control Systems

CNC Control, a leading provider of advanced manufacturing solutions, has recently unveiled its latest innovation in CNC control technology. The new CNC control system promises to revolutionize the industry with its state-of-the-art features and capabilities.The new CNC control system is designed to offer unparalleled precision and performance, enabling manufacturers to produce parts with higher accuracy and efficiency. The system is equipped with cutting-edge software and hardware, allowing for seamless integration with various machine tools and production processes. With its user-friendly interface and advanced programming functionalities, the new CNC control system is set to streamline manufacturing operations and improve overall productivity.In addition to its advanced technical features, the new CNC control system also boasts a range of intelligent functions that enable automated process monitoring and optimization. This will enable companies to reduce waste, minimize downtimes, and maximize the utilization of their resources.The CNC Control system is also designed with a focus on flexibility and scalability, allowing it to adapt to the specific needs and requirements of different manufacturing environments. Whether it's a small-scale workshop or a large-scale production facility, the CNC control system promises to deliver consistent and reliable performance, catering to a wide range of manufacturing applications."We are extremely excited to introduce our latest CNC control system to the market," said a spokesperson from CNC Control. "We have dedicated a significant amount of time and resources to research and development, ensuring that our new system meets the highest standards of performance and functionality. We believe that this new innovation will significantly elevate the capabilities of manufacturers and empower them to achieve new levels of efficiency and precision in their operations."As part of its commitment to providing comprehensive manufacturing solutions, CNC Control also offers extensive technical support, training, and maintenance services to ensure the seamless integration and ongoing performance of its CNC control systems. With a team of experienced engineers and technicians, CNC Control is dedicated to assisting customers in maximizing the potential of their manufacturing processes.The company also takes pride in its customer-centric approach, working closely with clients to understand their unique requirements and challenges. This allows CNC Control to offer tailored solutions that address specific needs and deliver tangible results. As a result, many manufacturers have come to rely on CNC Control as their trusted partner for enhancing their manufacturing capabilities.In addition to its technological expertise, CNC Control also places a strong emphasis on innovation and continuous improvement. By staying abreast of the latest industry trends and developments, CNC Control remains at the forefront of CNC control technology, consistently pushing the boundaries of what is possible in the manufacturing sector.With its latest CNC control system, CNC Control is poised to make a significant impact in the industry, setting new standards for precision, performance, and productivity. As manufacturing processes continue to evolve, CNC Control is committed to driving advancements and empowering manufacturers to achieve greater success in their operations.For more information about CNC Control and its innovative CNC control system, please visit their website or contact their sales team for further details.