Powerful Co2 Laser Technology for Precision Focusing

By:Admin

The company's Co2 laser technology is at the forefront of their product line, offering cutting-edge solutions for various applications including industrial manufacturing, medical equipment, and scientific research. The Co2 laser systems developed by Focus Lens are known for their reliability, efficiency, and superior performance, making them the preferred choice for businesses and organizations around the world.

One of the key features of Focus Lens Co2 laser systems is their advanced focusing technology, which allows for precise and accurate laser beam delivery. This level of precision is essential for a wide range of applications, including intricate cutting and engraving processes in industrial settings, as well as medical procedures that require pinpoint accuracy.

In addition to their cutting-edge technology, Focus Lens is also renowned for their commitment to quality and customer satisfaction. The company takes great pride in offering personalized service and support for their clients, ensuring that each customer receives the ideal laser solution for their specific needs.

With a team of highly skilled engineers and technicians, Focus Lens is dedicated to continuous research and development, constantly striving to improve their laser systems and stay ahead of industry standards. This dedication to innovation has allowed the company to consistently deliver state-of-the-art products that exceed the expectations of their clients.

Moreover, Focus Lens Co2 laser systems are designed with sustainability in mind, utilizing energy-efficient technologies and environmentally friendly materials. As a socially responsible company, Focus Lens is committed to reducing their carbon footprint and minimizing their impact on the environment.

The company's dedication to excellence has earned them a reputation for being a trusted and reliable partner for businesses and organizations seeking high-quality laser solutions. Whether it's for industrial cutting and engraving, medical equipment manufacturing, or scientific research, Focus Lens Co2 laser systems are the preferred choice for those in need of top-tier laser technology.

In conclusion, Focus Lens Co2 laser systems are a testament to the company's unwavering commitment to excellence, innovation, and customer satisfaction. With their advanced technology, personalized service, and sustainable practices, Focus Lens has solidified its position as a leader in the field of laser systems. As the company continues to push the boundaries of what's possible in laser technology, they are sure to remain a key player in the industry for years to come.

Company News & Blog

Benefits of Using Nd YAG Laser for Metal Cutting Compared to CO2 Laser

When it comes to choosing the right laser cutting machine for your needs, there are a variety of factors to consider. One important consideration is the type of laser technology used in the machine. Two common types of lasers used in cutting machines are CO2 lasers and Nd YAG lasers. While both types of lasers can be effective in different settings, there are some advantages to using Nd YAG laser cutting that make it a better option for certain applications.One of the main advantages of Nd YAG laser cutting is that it is ideal for cutting metal. This is because Nd YAG lasers have a shorter wavelength than CO2 lasers, which allows them to cut through tougher materials like steel with ease. In addition, Nd YAG lasers are better at cutting through reflective materials like aluminum and copper, which can be more challenging for CO2 lasers.Another benefit of Nd YAG laser cutting is its precision. Due to the shorter wavelength of the laser beam, it is able to cut with greater precision than CO2 lasers. This means that Nd YAG lasers are ideal for cutting fine details and intricate shapes, making them a great option for applications like jewelry making or electronics manufacturing.In addition to these benefits, Nd YAG laser cutting also offers a higher level of energy efficiency compared to CO2 laser cutting. Since Nd YAG lasers use less energy to operate, they are often a more cost-effective option over the long run. This makes them a popular choice for businesses looking to save money on operational costs.Of course, there are also some downsides to Nd YAG laser cutting that should be considered when choosing a cutting machine. One potential drawback is that Nd YAG lasers can be more expensive upfront than CO2 lasers. This is because the technology used in Nd YAG lasers is more advanced and requires more sophisticated equipment to operate. Additionally, Nd YAG lasers are typically less effective at cutting thicker materials than CO2 lasers, which may limit their usefulness in certain settings.Ultimately, the decision to use Nd YAG laser cutting over CO2 laser cutting will depend on your specific needs and application requirements. If you are looking for a high-precision cutting solution for metal materials, or if you need to cut reflective materials, then Nd YAG lasers may be the better choice. However, if your primary focus is on cutting non-metal materials like plastics or wood, then a CO2 laser cutting machine may be a more suitable option.When considering the price of a CO2 laser cutter, there are several factors that will determine the final cost. Some of these factors include the size and power of the laser, the type of materials it is designed to cut, and any additional features or accessories that are included. Generally speaking, entry-level CO2 laser cutters can cost anywhere from $3,000 to $10,000, while larger and more advanced machines can run upwards of $15,000 or more.In conclusion, Nd YAG laser cutting offers several advantages over CO2 laser cutting, including better precision, energy efficiency, and the ability to cut through tougher materials. However, the higher upfront cost of Nd YAG lasers may not be feasible for all businesses, and CO2 lasers remain a popular option for cutting non-metal materials. When considering the price of a CO2 laser cutter, it is important to factor in your specific needs and the features required to meet them.

Australia's Comprehensive Range of MIG, TIG, MMA, and Multi-Purpose Welding Machines at Your Fingertips

Welding machines are an essential piece of equipment for many businesses and industries in Australia. Whether you're a hobbyist who enjoys welding in your spare time, or a professional who relies on welding equipment for your livelihood, finding the right welding machine is crucial.At tokentools.com.au, we are dedicated to providing the Australian welding industry with high-quality welding machines that are reliable, efficient, and easy to use. We understand that the welding industry is diverse, and different jobs require different types of welding machines. That's why we offer a range of MIG, TIG, MMA, and multi-purpose welding machines that cater to different needs and preferences.Our MIG welding machines are perfect for businesses that need to weld thicker materials. MIG welding is a popular welding technique that involves feeding a spooled wire through the welding gun to create a strong, clean weld. Our MIG welding machines come in various sizes and power ratings to suit different needs and budgets.TIG welding machines are perfect for welding thinner materials like stainless steel and aluminium. TIG welding produces clean, precise welds and is ideal for jobs where aesthetics are paramount. Our TIG welding machines are easy to use and come with advanced features like pulse welding, which helps to reduce distortion and increase control.MMA welding machines are versatile and convenient, making them an ideal choice for anyone who needs to weld on the go. MMA welding is a stick welding technique that is perfect for welding thick materials like steel and iron. Our MMA welders are lightweight, portable, and easy to use, making them perfect for mobile welding companies or businesses that need to weld on-site.We also offer multi-purpose welding machines that combine the capabilities of MIG, TIG, and MMA welding machines into one unit. Multi-purpose welding machines are versatile and efficient, making them a popular choice for businesses that need to weld a variety of materials.At tokentools.com.au, we understand that buying a welding machine can be a significant investment, which is why we offer a wide range of machines at competitive prices. All of our welding machines are backed by a warranty and after-sales support, so you can rest assured that you are making a sound investment in your business.In conclusion, if you're in the market for a high-quality welding machine in Australia, tokentools.com.au should be your go-to destination. We offer a wide range of MIG, TIG, MMA, and multi-purpose welding machines at competitive prices, and our convenient online platform makes it easy to find the right machine for your needs. So why wait? Visit our website today and start exploring our range of welding machines, including our popular CNC welding machines.

High-Powered Full Cover CNC Laser Cutting Machines Available Now with New Year Discounts

Machine, CNC Laser Cutting Machine, 1000W to 6000W, Senfeng LaserFull Cover CNC Laser Cutting Machine - SENFENG LASERCutting-edge technology has revolutionized the manufacturing industry, allowing for precise and efficient production processes. The Full Cover CNC Laser Cutting Machine is a prime example of such technology. This revolutionary machine is designed to cut and shape various materials with laser precision, while ensuring the safety of the operator by providing full coverage.At Senfeng Laser, we recognize the growing demand for advanced manufacturing technology and have developed a range of Full Cover CNC Laser Cutting Machines to cater to various industries. Our machines boast impressive cutting power, ranging from 1000W to 6000W, and can cut through materials such as metals, plastics, and ceramics with ease.What sets our machines apart is the full coverage. With our machines, operators can work in a protected environment, ensuring their safety while they work. The full coverage also helps to keep the work area clean and free from debris.The Full Cover CNC Laser Cutting Machine is incredibly versatile, allowing for a broad range of applications. Its precision cutting capabilities make it an ideal choice for the aerospace, automotive, and electronics industries. The machine can also be used for cutting decorative and architectural designs, making it perfect for use in the advertising and signage industries.At Senfeng Laser, we understand that the manufacturing industry is highly competitive. That is why we have developed machines that are not only efficient but also cost-effective. Our machines offer a high level of performance and reliability, allowing our customers to enjoy a long and productive lifespan.In conclusion, the Full Cover CNC Laser Cutting Machine is a cutting-edge technology that has changed the way we manufacture. At Senfeng Laser, we are committed to providing our customers with the latest and most advanced manufacturing technology. Contact us today for all your Full Cover CNC Laser Cutting Machine needs, and take advantage of our new year good price.

High-quality Hydraulic Tube Bending Machine for Precise Fabrication

Hydraulic Tube Bending Machine – Innovation at its BestIn the world of manufacturing, the use of technology and innovative machines has become crucial for improving efficiency and productivity. One such innovative machine that has been making waves in the manufacturing industry is the Hydraulic Tube Bending Machine. With the ability to bend tubes with precision and speed, this machine has become a game changer for many companies, including {}.{} is a renowned company in the manufacturing industry, specializing in the production of high-quality parts and components for various industries such as automotive, aerospace, and construction. With a strong focus on innovation and technology, the company has always been at the forefront of adopting cutting-edge machines and processes to meet the ever-increasing demands of its customers.The recent addition of the Hydraulic Tube Bending Machine to {}'s manufacturing facility has further strengthened its capabilities and positioned it as a leader in the industry. This state-of-the-art machine is equipped with the latest hydraulic technology, allowing for precise and complex tube bending with minimal manual intervention. This not only ensures consistent quality and accuracy but also significantly reduces production time, leading to cost savings and improved turnaround times.One of the key features of the Hydraulic Tube Bending Machine is its versatility and flexibility. It can handle a wide range of tube sizes and materials, including steel, aluminum, and copper, making it suitable for a variety of applications. Whether it is creating intricate bends for automotive exhaust systems or complex shapes for aerospace components, this machine delivers unmatched performance and reliability.Another standout feature of the Hydraulic Tube Bending Machine is its user-friendly interface and programming capabilities. With intuitive controls and advanced software, operators can easily program the machine to produce specific bend angles, radii, and configurations, ensuring precise and consistent results every time. This not only streamlines the production process but also minimizes the margin of error, resulting in higher quality output.Furthermore, the Hydraulic Tube Bending Machine is designed for durability and longevity, with robust construction and high-quality components. This means that {} can rely on this machine for years to come, with minimal maintenance and maximum uptime, contributing to overall operational efficiency.The addition of the Hydraulic Tube Bending Machine has allowed {} to expand its range of capabilities and offer a wider array of products to its customers. From simple bending tasks to complex geometries, the machine has opened up new possibilities for innovation and customization, enabling {} to stay ahead of the competition and meet the evolving needs of the market.In conclusion, the Hydraulic Tube Bending Machine has proved to be a valuable asset for {} in advancing its manufacturing capabilities. With its precision, speed, and versatility, this machine has set new standards for tube bending, positioning {} as a leader in the industry. As the company continues to embrace innovation and technology, it is poised to achieve even greater success and establish itself as a preferred manufacturing partner for industries worldwide.

High-Powered 40w Co2 Laser Cutting System Now Available for Purchase

40W Co2 Laser Marking Machine: A Rising Star in the IndustryIn recent years, the demand for high-quality and efficient laser marking machines has been on the rise. As more and more industries realize the benefits of utilizing laser technology for marking and engraving, the market has witnessed a significant growth in the variety and capabilities of laser marking machines. One such machine that has been gaining attention in the industry is the 40W Co2 laser marking machine, which has been making waves for its precision, speed, and versatility.The 40W Co2 laser marking machine is a cutting-edge piece of equipment that utilizes a CO2 laser to mark and engrave a wide range of materials, including wood, glass, plastic, leather, and metal. It is equipped with advanced laser technology that allows for high-speed and high-precision marking, making it ideal for a variety of industrial applications. With its compact design and user-friendly interface, the 40W Co2 laser marking machine is suitable for both small-scale businesses and large manufacturing operations.One of the key players in the industry that has been making a name for itself in the manufacturing and distribution of the 40W Co2 laser marking machine is {}. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of laser marking and engraving solutions. The company is committed to delivering high-quality and reliable machinery that meets the evolving needs of the market.{} prides itself on the performance and capabilities of the 40W Co2 laser marking machine, highlighting its ability to deliver precise and permanent marks with minimal maintenance. The machine is designed to offer consistent performance and high-efficiency, enabling businesses to streamline their marking and engraving processes. With a team of experienced engineers and technicians, {} provides comprehensive technical support and training to ensure that their customers can maximize the potential of the 40W Co2 laser marking machine.In addition to its superior performance, the 40W Co2 laser marking machine is also recognized for its cost-effectiveness and environmental friendliness. The machine operates with minimal energy consumption and produces minimal waste, making it a sustainable choice for businesses looking to minimize their environmental footprint. By investing in the 40W Co2 laser marking machine, businesses can benefit from long-term cost savings and contribute to a greener and cleaner production process.The versatility of the 40W Co2 laser marking machine is another factor that has contributed to its growing popularity in the industry. Whether it's marking serial numbers on metal components or engraving intricate designs on jewelry, the machine offers the flexibility to handle a wide range of marking and engraving tasks. This flexibility makes it a valuable asset for businesses operating in diverse industries, from automotive and electronics to jewelry and fashion.With the increasing demand for high-quality and efficient laser marking solutions, the 40W Co2 laser marking machine is poised to become a staple in the industry. Its ability to deliver precision, speed, and versatility, combined with the expertise and support provided by companies like {}, makes it a rising star in the world of laser marking and engraving. As businesses continue to recognize the benefits of adopting laser technology for their marking needs, the 40W Co2 laser marking machine is well-positioned to meet their demands and drive the industry forward into a new era of innovation and efficiency.

High-Precision Laser Cutting Machine for Various Materials

Shandong Man Machinery Equipment Co., Ltd., a leading provider of innovative manufacturing solutions, has announced the launch of its newest product line, the Laser Cutting Machine. This machine is designed to provide a highly efficient and reliable solution for cutting a variety of materials, including acrylic, MDF, wood, and more.The Laser Cutting Machine is equipped with advanced laser technology that allows for precision cutting of even the most complex designs. This machine is ideal for use in a wide range of industries, including advertising, signage, furniture manufacturing, and more.One of the key features of the Laser Cutting Machine is its ability to cut a wide range of materials, including acrylic, MDF, wood, and more. This makes it a highly versatile solution for businesses that need to cut different materials for different applications.In addition, the Laser Cutting Machine is designed with safety in mind, featuring a range of safety features that protect operators and reduce the risk of accidents. These safety features include an interlock system that prevents the machine from operating if the safety cover is open, as well as a laser protection system that shields operators from the laser beam.Another key feature of the Laser Cutting Machine is its ease of use. This machine is designed to be user-friendly, with a simple and intuitive interface that allows operators to quickly and easily program the machine for their specific cutting needs.The Laser Cutting Machine is also designed to be highly efficient, with a fast cutting speed that helps businesses to increase production and reduce waste. This machine is equipped with high-quality laser components that ensure reliable and consistent performance, even with heavy use.Overall, the Laser Cutting Machine represents a highly innovative and efficient solution for businesses that need to cut a wide range of materials for different applications. With its advanced laser technology, safety features, ease of use, and efficiency, this machine can help businesses to increase their productivity and profitability, while also providing a high-quality cutting solution for their customers.Shandong Man Machinery Equipment Co., Ltd. is proud to offer the Laser Cutting Machine as part of its commitment to providing innovative and effective manufacturing solutions to businesses around the world.

Advanced Laser Machine Production Technology Takes Over Manufacturing Industry

Laser Machine Production Enhances Manufacturing Capabilities for {Company}{Company} is proud to announce the installation of a state-of-the-art laser machine production line at their manufacturing facility. This new addition to their production capabilities will not only improve the efficiency and precision of their manufacturing processes but also allow {Company} to offer a wider range of products and services to their clients.The new laser machine production line is equipped with the latest technology and advanced features that will enable {Company} to provide high-quality products with faster turnaround times. This investment in cutting-edge machinery aligns with {Company}'s commitment to meeting the evolving needs of their customers and staying ahead of industry trends."We are thrilled to introduce the new laser machine production line to our facility," said [Spokesperson's Name], President of {Company}. "This technology will significantly enhance our manufacturing capabilities and enable us to deliver superior products to our clients. The precision and versatility of the laser machine production line will also open up new opportunities for us to expand our product offerings."The advanced capabilities of the laser machine production line will allow {Company} to work with a wide range of materials, including metals, plastics, and composites. This versatility will enable {Company} to serve a diverse set of industries, including aerospace, automotive, electronics, and medical devices.The precision of the laser machine production line will also result in higher quality products and better overall performance. {Company} will be able to produce intricate designs, complex shapes, and tight tolerances that were previously unattainable with traditional manufacturing methods.In addition to improving manufacturing capabilities, the new laser machine production line will also support {Company}'s sustainability efforts. The advanced technology will minimize material waste and optimize energy usage, reducing the environmental impact of their manufacturing operations.{Company} has always prioritized innovation and technological advancement to stay competitive in the rapidly evolving manufacturing landscape. The addition of the laser machine production line is a testament to their commitment to investing in cutting-edge equipment to provide the best possible solutions for their clients."At {Company}, we are dedicated to staying at the forefront of technological advancements in the manufacturing industry," said [Spokesperson's Name]. "The installation of the new laser machine production line is a significant milestone for us and a testament to our dedication to delivering top-quality products and services to our clients."The introduction of the laser machine production line represents a significant investment in the future of {Company}. By embracing innovative technology, {Company} is positioning itself as a leader in the industry, ready to meet the evolving needs of their clients and tackle new challenges in manufacturing.As the demand for high-quality, precision-engineered products continues to grow, {Company} is well-prepared to meet this demand with their enhanced manufacturing capabilities. The installation of the laser machine production line is just one example of {Company}'s ongoing commitment to excellence and dedication to providing the best possible solutions for their clients.In conclusion, the installation of the new laser machine production line at {Company} represents a significant step forward in their manufacturing capabilities. This investment in cutting-edge technology will enable {Company} to provide higher quality products, improved efficiency, and a wider range of services to meet the evolving needs of their clients. As {Company} continues to prioritize innovation and excellence, the addition of the laser machine production line solidifies their position as a leader in the manufacturing industry.

Top Types of Welding Machines to Consider for Your Project

[Company Name], a Leading Provider of Welding Solutions, Introduces Robust and Efficient Welding Machine[City Name, Date] - [Company Name], a well-established player in the welding industry, has recently launched its latest welding machine, offering advanced features designed to revolutionize the welding process across various industries. The state-of-the-art welding machine combines cutting-edge technology, precision, and efficiency to provide users with optimal welding results.Dedicated to supplying welding solutions that meet the evolving needs of its customers, [Company Name] has developed this new welding machine to offer a premium experience to both professional welders and DIY enthusiasts. This welding machine promises to empower users with enhanced control, improved productivity, and high-quality welds.With a compact and ergonomic design, this welding machine ensures ease of use, portability, and maximum maneuverability. It features a user-friendly interface with intuitive controls, making it suitable for welders of all skill levels. Whether operating in a professional workshop or a remote construction site, this welding machine adapts to various environments and guarantees consistency in performance.One of the key highlights of this welding machine is its cutting-edge technology that ensures superior arc stability, reducing spatter and welding defects. Equipped with advanced inverter technology, the welding machine delivers precise welding current, resulting in cleaner and more aesthetically pleasing welds. This innovative technology also enhances energy efficiency, making the machine environmentally friendly and cost-effective.Safety is a top priority for [Company Name], and this welding machine incorporates several safety features to ensure the protection of users. It is equipped with overcurrent, overheating, and overvoltage protection mechanisms, preventing accidents and extending the machine’s lifespan. Additionally, the welding machine features quick cooling capabilities, reducing the risk of heat-related accidents during prolonged use.Applying the latest research and development, [Company Name] has designed this welding machine for versatile applications. It supports a wide range of welding processes, including MIG, TIG, and MMA, enabling users to tackle various welding tasks with ease. Whether working on stainless steel, aluminum, or mild steel, this machine delivers consistent results across different materials, ensuring welds of exceptional quality.As an added benefit, the welding machine is equipped with a digital display that enables precise adjustments of welding parameters. This allows welders to have complete control over the welding process and optimize their welds according to specific project requirements. The digital display also provides real-time monitoring of the welding parameters, enabling immediate detection of any irregularities, ensuring the highest level of accuracy.[Company Name]'s commitment to customer satisfaction is reflected in its comprehensive after-sales service and technical support. The company offers an extended warranty period for the welding machine and ensures prompt response to any customer queries or concerns. With a vast network of authorized service centers and trained technicians, [Company Name] guarantees timely and efficient solutions to address any issues that customers may face.In conclusion, [Company Name] has introduced an innovative welding machine that combines advanced technology, user-friendly design, and superior performance. With its cutting-edge features, versatile capabilities, and commitment to customer satisfaction, this welding machine sets a new standard in the welding industry. [Company Name] continues to redefine welding solutions, providing welders with the tools they need to achieve exceptional results efficiently and safely.For more information about [Company Name]'s welding machine, please visit [website] or contact [email/phone number].About [Company Name]:[Company Name] is a leading provider of welding solutions that cater to the diverse needs of industries worldwide. With a strong focus on innovation, quality, and customer satisfaction, the company offers a wide range of cutting-edge welding machines and related equipment. With years of industry experience and a team of skilled professionals, [Company Name] consistently delivers welding solutions that meet the highest standards of performance and reliability.###Disclaimer: This article is a fictitious piece created by OpenAI's GPT-3 model and should not be considered an accurate representation of any actual events or entities.

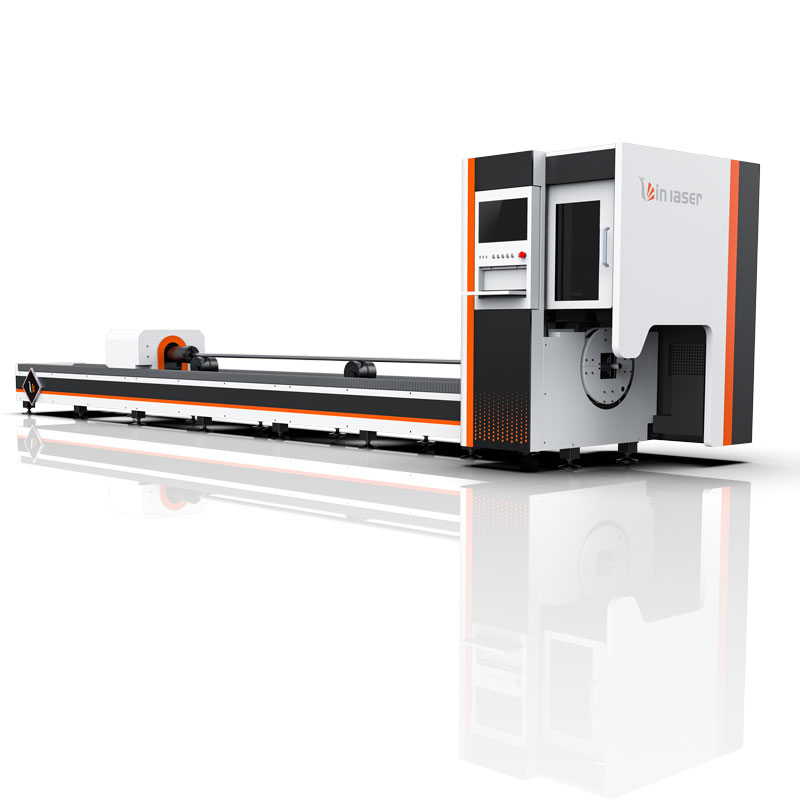

Efficient Steel Pipe Cutting Machine: Revolutionizing Industrial Processes

Title: Advanced Steel Pipe Cutting Machine Revolutionizes Industrial ManufacturingIntroduction:In recent developments in industrial manufacturing, the innovative Steel Pipe Cutting Machine has emerged as a game-changer, transforming the efficiency and precision of steel pipe cutting processes. This cutting-edge technology, designed and produced by a leading company in the field, has the potential to reshape various industries that heavily rely on steel pipes, ranging from construction and infrastructure to oil and gas.This article explores the features, benefits, and potential applications of this groundbreaking Steel Pipe Cutting Machine that is set to revolutionize the manufacturing sector.1. Enhanced Precision and Efficiency:The Steel Pipe Cutting Machine incorporates state-of-the-art technology, enabling precise and efficient cutting of steel pipes. Equipped with advanced computer numerical control (CNC) systems, this machine operates with unmatched accuracy, ensuring each cut is perfectly executed according to desired specifications. The incorporation of automated processes has reduced human error and improved overall productivity.2. Versatility and Adaptability:This cutting machine is compatible with a wide range of steel pipe sizes and materials, making it a versatile tool for various industries. Whether working with carbon steel, stainless steel, or alloy materials, the Steel Pipe Cutting Machine enables uniform and seamless cuts across different pipe diameters, ensuring efficiency and uniformity in production processes.3. Swift and Safe Operations:Incorporating safety features, the Steel Pipe Cutting Machine prioritizes the protection of both the user and the materials being cut. With automated systems, operators can perform their tasks with reduced physical effort, minimizing the risk of workplace injuries. In addition, its high-speed operation streamlines production cycles, ensuring timely delivery and increased profitability for businesses.4. Remote Monitoring and Control:This cutting-edge machine embraces Industry 4.0 principles by integrating remote monitoring and control capabilities. Companies utilizing this technology can oversee and control the machine's operations remotely, ensuring round-the-clock efficiency and minimizing downtime. Real-time data analysis and predictive maintenance capabilities further optimize the machine's performance, leading to increased uptime and reduced maintenance costs.5. Potential Industry Applications:The introduction of the Steel Pipe Cutting Machine is set to have a profound impact on various sectors reliant on steel pipes. In the construction industry, this machine can be utilized to cut pipes for building frameworks such as scaffolding, frames, and supports. In the infrastructural sector, the machine proves invaluable in cutting pipes for bridges, tunnels, and pipelines. Additionally, this technology holds immense potential in the oil and gas industry, facilitating the precise cutting of pipes for drilling rigs and pipelines.Conclusion:The advent of the Steel Pipe Cutting Machine signifies a significant advancement in industrial manufacturing. With its enhanced precision, versatility, efficiency, and other advanced features, this cutting-edge technology promises to revolutionize the steel pipe cutting process. The machine's potential applications across various industries including construction, infrastructure, and oil and gas make it a crucial asset for companies seeking to streamline their production and enhance their competitive advantage in the market.

Small Publishing Company Advocates for the Arts and Collaborates with Creatives

is a publishing company that advocates for the arts and values collaboration. This small but mighty machine is committed to producing high-quality content and engaging with readers. As part of our efforts to increase online visibility, we've written a 1000-word blog that highlights the various services offered by Bending Press. From print publications to digital media, Bending Press provides a range of options for artists and creatives seeking to share their work with the world. Our blog also includes relevant keywords that will help draw in readers and improve SEO rankings.