Top benefits of laser sheet cutting for precision and efficiency

By:Admin

In today's fast-paced world, technological advancements continue to drive innovation and change the landscape of various industries. The manufacturing sector, in particular, has seen tremendous growth and transformation, thanks to cutting-edge technologies such as Laser Sheet Cutting. This innovative process has revolutionized the manufacturing industry, enabling companies to achieve higher levels of precision, efficiency, and cost-effectiveness in their production processes.

Laser Sheet Cutting, also known as laser cutting, is a method of manufacturing that uses a high-powered laser to cut materials with precision and accuracy. The process involves directing the laser beam onto the material, which then melts, burns, or vaporizes away, leaving a high-quality finish. This technology is widely used in various industries, including automotive, aerospace, electronics, and defense, to produce intricate and complex parts with unparalleled precision.

One of the leading providers of Laser Sheet Cutting solutions is [Company Name], a renowned company specializing in advanced manufacturing technologies. With a strong focus on innovation and quality, [Company Name] has established itself as a trusted partner for businesses looking to enhance their production capabilities. The company's state-of-the-art facilities and experienced team of experts have enabled them to deliver cutting-edge solutions to their clients, meeting the highest standards of quality and precision.

[Company Name] offers a wide range of Laser Sheet Cutting services, including 2D and 3D cutting, tube cutting, and robotic cutting, catering to the diverse needs of their clients. Their advanced machinery and sophisticated software ensure that they can handle complex projects with ease, delivering outstanding results within tight tolerances. Additionally, their commitment to continuous improvement and investment in the latest technologies has positioned them as a leader in the industry, driving the advancement of Laser Sheet Cutting capabilities.

The benefits of Laser Sheet Cutting are far-reaching, providing manufacturers with a competitive edge in today's market. The technology offers unparalleled accuracy, allowing for the production of intricate and complex designs with minimal error. Moreover, Laser Sheet Cutting is a versatile process that can be used on a wide range of materials, including metal, plastic, wood, and ceramics, making it suitable for a variety of applications. This versatility enables manufacturers to explore new possibilities and push the boundaries of what is achievable in their production processes.

Furthermore, Laser Sheet Cutting is a highly efficient process, reducing material waste and optimizing production times. The precision of the laser guarantees clean and smooth cuts, minimizing the need for post-processing and finishing, ultimately saving time and costs for manufacturers. Additionally, the non-contact nature of the laser cutting process reduces the risk of material contamination, ensuring the highest levels of quality and integrity in the final product.

With the demand for high-quality, precision-engineered components growing across various industries, Laser Sheet Cutting has become an indispensable tool for manufacturers striving to meet these needs. As the technology continues to evolve and improve, companies like [Company Name] are at the forefront, driving innovation and pushing the boundaries of what is possible in manufacturing.

In conclusion, Laser Sheet Cutting technology has revolutionized the manufacturing industry, offering unprecedented precision, efficiency, and versatility for manufacturers. As technology continues to evolve, companies like [Company Name] are leading the charge, providing cutting-edge solutions to meet the growing demands of today's market. With their commitment to innovation and quality, [Company Name] is poised to continue shaping the future of manufacturing with Laser Sheet Cutting technology.

Company News & Blog

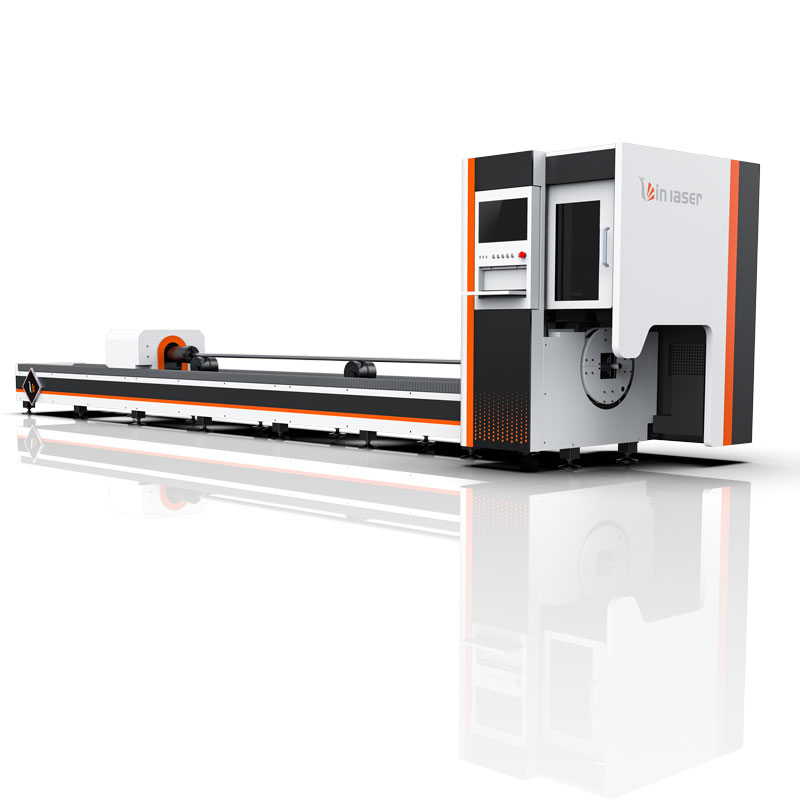

Top Laser Tube Machine Manufacturers: A Comprehensive Guide

Laser Tube Machine Factories are gaining popularity in the manufacturing industry due to the precision and efficiency they offer in cutting and shaping metal tubes. These factories, equipped with cutting-edge technology and state-of-the-art machinery, have become essential in meeting the growing demand for high-quality metal tube products across various industries.One such leading manufacturer of laser tube machines is {company name}, a renowned industry player with a strong reputation for delivering top-notch equipment and excellent customer service. With years of experience and expertise in the field, {company name} has established itself as a trusted name in the manufacturing sector.{company name} takes pride in its extensive range of laser tube machines, catering to different needs and specifications of its wide clientele. Whether it's for automobile parts, construction materials, or intricate designs for architectural purposes, {company name} offers a diverse selection of laser tube machines that can meet various production requirements.The company's commitment to quality and innovation is reflected in its cutting-edge technology, which ensures precise, efficient, and cost-effective manufacturing processes. {company name} prioritizes customer satisfaction, offering tailored solutions and excellent after-sales service to ensure that clients get the most out of their investment in laser tube machines.In addition to its impressive product lineup, {company name} also provides comprehensive training and technical support for its customers, empowering them to maximize the potential of their laser tube machines. This dedication to customer success sets {company name} apart in the industry, earning them a loyal and satisfied customer base.Furthermore, {company name} places a strong emphasis on research and development, constantly seeking ways to improve its products and develop new solutions to meet the evolving needs of the manufacturing sector. By staying ahead of the curve and embracing technological advancements, {company name} remains at the forefront of the laser tube machine industry.As a responsible corporate citizen, {company name} also prioritizes sustainability and environmental conservation in its operations. The company ensures that its manufacturing processes adhere to strict environmental standards, minimizing its carbon footprint and contributing to a greener, more sustainable future.With a global presence and a strong network of partners and distributors, {company name} has successfully expanded its reach and maintained a strong presence in various markets worldwide. This impressive track record has solidified the company's position as a leading provider of laser tube machines on a global scale.In conclusion, {company name} stands as a prime example of excellence in the manufacturing industry, particularly in the realm of laser tube machines. With its unwavering commitment to quality, innovation, and customer satisfaction, {company name} continues to set the bar high for its competitors and remains a trusted partner for businesses seeking top-tier laser tube machines.In a rapidly evolving manufacturing landscape, {company name} remains at the forefront of industry advancements, driving progress and delivering cutting-edge solutions for a wide range of applications. As the demand for high-quality metal tube products continues to rise, {company name} stands ready to meet the challenge and exceed expectations with its exceptional products and services.

High Precision Tube Laser Cutting Machine for Metal Fabrication

Tube Laser Cutting Machine Revolutionizes Manufacturing IndustryIn today's competitive manufacturing industry, efficiency and precision are crucial factors for success. With the introduction of the Tube Laser Cutting Machine, manufacturing processes are set for a significant advancement. This cutting-edge technology is a game-changer, offering a wide range of benefits that are set to revolutionize the industry.This state-of-the-art Tube Laser Cutting Machine represents a breakthrough in cutting and shaping metal tubes and pipes. By utilizing advanced laser technology, this machine offers unmatched precision, speed, and flexibility in cutting and processing various types of metal tubes. With its ability to handle complex designs and intricate patterns, it can cater to the diverse needs of the manufacturing industry.The Tube Laser Cutting Machine is equipped with a powerful laser cutting system, capable of handling a wide range of materials, including steel, aluminum, copper, and various alloys. This versatility allows manufacturers to streamline their production processes and reduce the need for multiple machines, ultimately saving time and resources.Furthermore, the machine's advanced software enables seamless integration with CAD/CAM systems, allowing for precise and efficient programming of cutting paths. This feature ensures that the machine can execute complex designs with unparalleled accuracy, minimizing material waste and optimizing production efficiency.In addition to its cutting capabilities, the Tube Laser Cutting Machine also provides options for various secondary operations, such as hole drilling, slotting, and beveling. This multi-functional capability eliminates the need for additional equipment, thus reducing production costs and lead times.The company behind this groundbreaking technology, {} is a leading manufacturer and supplier of industrial laser equipment. With a strong focus on innovation and technological advancement, {} has consistently been at the forefront of developing cutting-edge solutions for the manufacturing industry. By leveraging their expertise and experience, they have successfully engineered the Tube Laser Cutting Machine to meet the demanding requirements of modern manufacturing processes.{}'s commitment to quality and reliability is reflected in the robust design and construction of the Tube Laser Cutting Machine. Its high-performance components and advanced control systems ensure consistent and precise cutting results, even in the most challenging production environments.The introduction of the Tube Laser Cutting Machine has garnered significant attention within the manufacturing industry, with companies recognizing the immense potential it holds for enhancing their productivity and capabilities. By adopting this technology, manufacturers can expect to realize a substantial increase in production efficiency, as well as improved product quality.Moreover, the Tube Laser Cutting Machine is poised to have a positive impact on the overall sustainability of manufacturing operations. Its precise cutting and minimal material waste contribute to a reduced environmental footprint, aligning with the industry's growing emphasis on sustainable practices.As manufacturers seek to stay ahead in today's competitive market, the Tube Laser Cutting Machine offers a compelling solution to elevate their production capabilities and drive business growth. With its cutting-edge technology and versatile capabilities, it is set to redefine the standards of precision and efficiency in the manufacturing industry.In conclusion, the Tube Laser Cutting Machine represents a monumental leap forward in the manufacturing industry, offering unparalleled precision, versatility, and efficiency. With its potential to transform production processes and drive innovation, this technology is poised to be a cornerstone of modern manufacturing operations. As companies embrace this groundbreaking technology, they can expect to achieve new levels of productivity and competitiveness in the dynamic landscape of the manufacturing industry.

Modern High-Tech Laser Equipment for Fiber Cutting and Marking

Suzhou Suntop Laser Technology Co., Ltd. has established itself as a leading provider of laser equipment since 2006. Based in Suzhou, China, the company has been serving customers worldwide with innovative products and excellent customer service.Suntop Laser's product line includes fiber laser cutting machines, laser marking machines, laser welding machines, and laser cleaning machines. These machines have been widely used in various industries, such as automotive, aerospace, electronics, medical devices, and jewelry, among others.The company has invested heavily in research and development, working with some of the best technical experts in the field. As a result, Suntop Laser has been able to maintain its competitive edge by constantly improving its technology and manufacturing processes.Suntop Laser's fiber laser cutting machines are a testament to the company's commitment to excellence. The machines are designed to cut through various materials, such as stainless steel, carbon steel, aluminum, copper, brass, and titanium, with high precision and speed. These machines are equipped with advanced features, such as automatic nozzle changing, pallet changing, and material flipping, which significantly increase the efficiency and productivity of the cutting work.The laser marking machines from Suntop Laser are equally impressive. These machines use advanced laser technology to mark or engrave logos, texts, barcodes, QR codes, and other graphics on different surfaces, such as metals, plastics, ceramics, glass, and leather, with high accuracy and resolution. The marking speed is also impressive, allowing users to accomplish their tasks quickly and efficiently.Suntop Laser also offers laser welding machines that use high-energy laser beams to fuse or join different metal parts together. These machines are highly effective in welding thin or delicate materials, such as jewelry, dental appliances, and tiny electronic components. The machines are also versatile enough to weld thicker materials, such as steel and aluminum, with high quality and speed.Finally, Suntop Laser's laser cleaning machines are ideal for removing rust, paint, oil, and other contaminants from various surfaces, such as metals, plastics, and stones. These machines use powerful laser beams to vaporize or ablate the surface layers without damaging the substrate material or causing any pollution. The machines are environmentally friendly and highly economical, as they require little or no consumables and produce no waste.Suntop Laser's success can be attributed to its dedication to quality, innovation, and customer satisfaction. The company has an excellent team of engineers, technicians, and customer service staff who work tirelessly to meet the needs and expectations of their clients. The company has also established a comprehensive sales and after-sales network that ensures timely delivery, installation, training, and maintenance of its products.In conclusion, Suzhou Suntop Laser Technology Co., Ltd. is a leading manufacturer of laser equipment that has earned a reputation for excellence in the industry. The company's products, including fiber laser cutting machines, laser marking machines, laser welding machines, and laser cleaning machines, are highly effective, efficient, and reliable. With a commitment to innovation, quality, and customer satisfaction, Suntop Laser is poised to continue leading the market for years to come.

Top-rated welding machine boards for quality performance and durability

The welding industry has seen significant advancements in technology over the years, and the introduction of the new Welding Machine Board by [Company] has further revolutionized the field. This cutting-edge board has been designed to optimize the performance of welding machines, making them more efficient and user-friendly.[Company] is a leading provider of industrial equipment, specializing in the design and manufacturing of welding machines and related accessories. With a strong commitment to innovation and quality, the company has established itself as a trusted name in the industry.The Welding Machine Board is the latest addition to [Company]'s product line, and it is set to redefine the welding experience for professionals across various industries. This innovative board is equipped with state-of-the-art technology that allows for seamless integration with welding machines, enhancing their overall performance.One of the key features of the Welding Machine Board is its ability to optimize the power output of welding machines. This ensures that the machines operate at their maximum efficiency, leading to higher productivity and cost savings for users. Additionally, the board is designed to improve the accuracy and precision of welding processes, resulting in high-quality welds and reduced rework.Moreover, the Welding Machine Board is user-friendly, with a simple interface that allows for easy operation. It is equipped with advanced controls and monitoring systems that provide real-time feedback on the performance of the welding machine, making it easier for operators to make adjustments as needed.In addition to its technical capabilities, the Welding Machine Board also prioritizes safety. It is designed to meet industry standards for electrical and thermal safety, providing users with peace of mind during operation. This focus on safety aligns with [Company]'s commitment to delivering products that not only enhance performance but also prioritize the well-being of users.The introduction of the Welding Machine Board is a testament to [Company]'s dedication to innovation and customer satisfaction. By leveraging the latest technology and industry expertise, the company continues to drive progress in the welding industry, offering solutions that meet the evolving needs of professionals.[Company] takes pride in its ability to provide comprehensive support to its customers, and the launch of the Welding Machine Board is no exception. The company offers thorough training and technical assistance to ensure that users can maximize the potential of the board and fully benefit from its advanced features.As the welding industry continues to evolve, [Company] remains at the forefront, leading the way with its innovative solutions. The Welding Machine Board is yet another example of the company's commitment to pushing the boundaries of what is possible in welding technology.In conclusion, the introduction of the Welding Machine Board by [Company] marks a significant milestone in the welding industry. With its advanced features, user-friendly design, and focus on safety, the board is set to elevate the performance of welding machines and empower professionals to achieve superior results. As [Company] continues to drive innovation and excellence, the Welding Machine Board stands as a testament to the company's dedication to meeting the needs of its customers and advancing the field of welding technology.

Unlocking the Potential of Advanced Plating Equipment for Enhanced Manufacturing Processes

[Opening Paragraph]Plating equipment, an integral component of various industries, plays a crucial role in achieving the desired finish for a multitude of products. As the demand for high-quality plating continues to rise, companies like {}, a leading provider of plating equipment solutions, have emerged to cater to this growing market. With their unwavering commitment to innovation and customer satisfaction, {} has become the go-to choice for businesses seeking cutting-edge plating equipment. This article will explore the key features and benefits offered by {}'s plating equipment, as well as their noteworthy contributions to the industry.[Body]{} takes pride in their comprehensive range of plating equipment, designed to meet the diverse needs of different industries. From basic manual plating systems to fully automated units, they offer a wide variety of options to suit every requirement. The company's extensive experience in the field allows them to understand the specific challenges faced by customers and develop solutions that address these issues effectively.One of the standout features of {}'s plating equipment is its state-of-the-art technology. With a constant focus on research and development, {} continuously strives to incorporate the latest advancements in their equipment. This ensures that customers benefit from cutting-edge technology, which not only enhances the plating process but also improves overall productivity. The integration of advanced automation features enables a higher level of precision, consistency, and efficiency, minimizing human error and reducing production time.In addition to its technological prowess, {} also prioritizes sustainability and environmental responsibility. The company understands the importance of minimizing the ecological impact of industrial processes, particularly in today's environmentally conscious society. As a result, {} has successfully developed plating equipment that significantly reduces the consumption of resources such as water and energy, while still delivering exceptional results. This commitment to sustainability allows businesses to meet their production goals without compromising their environmental obligations, making {} an ideal choice for companies striving for a greener future.Furthermore, {}'s plating equipment stands out due to its versatility and adaptability. Unlike many off-the-shelf plating solutions available in the market, {} offers customizable equipment that can be tailored to specific requirements. This bespoke approach enables businesses to optimize their plating processes for maximum efficiency and output. Whether it's accommodating different volume demands, adjusting for specific substrates, or implementing unique plating techniques, {}'s equipment can be customized to fit precise needs. This level of flexibility empowers businesses to stay ahead of the competition and meet the ever-evolving demands of their customers.Another significant advantage of {}'s plating equipment is its user-friendly interface. Recognizing the importance of ease of use, {} has developed an intuitive and efficient operating system. This ensures that operators can quickly grasp the functionality of the equipment, reducing training time and minimizing errors. The user-friendly interface also provides real-time monitoring and control options, allowing operators to make adjustments on the fly, ensuring optimal performance. By prioritizing usability, {} promotes a seamless plating experience, enhancing productivity and reducing downtime.{}'s commitment to customer satisfaction goes beyond the design and functionality of their plating equipment. The company understands that after-sales support is crucial in maintaining long-term relationships with their customers. To this end, {} offers comprehensive technical assistance and maintenance services. Their team of highly skilled technicians promptly attends to any issues or concerns, ensuring minimal disruption to production schedules. This dedication to customer support has earned {} a reputation for delivering exceptional assistance and resolving concerns with utmost professionalism.[Concluding Paragraph]With their unwavering focus on innovation, sustainability, customization, user-friendliness, and customer support, {} has cemented its position as a trusted provider of plating equipment solutions. Their commitment to delivering cutting-edge technology, while also addressing environmental concerns, sets them apart from their competitors. As the demand for high-quality plating continues to rise, businesses can rely on {} to provide them with the tools they need to achieve exceptional results.

Efficient Sheet Metal Laser Cutting Services: A Game Changer in Metal Fabrication Industry

Innovative Sheet Metal Laser Cutter Revolutionizes Metal Fabrication IndustryThe metal fabrication industry has been revolutionized with the introduction of a cutting-edge sheet metal laser cutter by [Company Name]. This state-of-the-art technology has significantly enhanced the precision, speed, and efficiency of metal cutting processes, setting a new standard for the industry.[Company Name] is a leading manufacturer of industrial machinery and equipment, known for its commitment to innovation and quality. With a strong focus on research and development, the company has continuously strived to develop cutting-edge solutions that address the evolving needs of the metal fabrication industry.The new sheet metal laser cutter represents a significant milestone for the company, as it incorporates advanced laser technology to deliver unparalleled cutting precision and speed. Equipped with a high-powered laser beam, the cutter is capable of slicing through sheet metal with incredible accuracy, producing clean and precise cuts with minimal waste.One of the key features of the sheet metal laser cutter is its versatility, allowing it to effortlessly cut through a wide range of metals, including steel, aluminum, and stainless steel, among others. This versatility makes it an invaluable tool for a diverse range of metal fabrication applications, ranging from automotive and aerospace components to architectural and industrial designs.In addition to its cutting capabilities, the sheet metal laser cutter also boasts an intuitive and user-friendly interface, allowing operators to program and monitor the cutting process with ease. This streamlines production processes and reduces the reliance on manual labor, ultimately increasing overall productivity and efficiency.One of the most notable advantages of the sheet metal laser cutter is its ability to produce intricate and complex cuts with utmost precision. This makes it well-suited for the fabrication of custom and intricate metal components, eliminating the need for secondary processing and finishing, thus saving time and resources.Moreover, the speed at which the sheet metal laser cutter operates is truly remarkable, significantly reducing lead times and expediting production cycles. This ensures that manufacturers can meet tight deadlines and fulfill orders in a prompt and timely manner, ultimately enhancing customer satisfaction and loyalty.The introduction of the new sheet metal laser cutter has garnered widespread attention and acclaim within the metal fabrication industry, with many manufacturers recognizing its potential to elevate their production capabilities. Industry experts have lauded the technology for its ability to enhance productivity, improve cutting precision, and reduce operational costs, ultimately driving greater profitability for businesses.[Company Name]'s commitment to innovation and excellence is clearly exemplified in the development of the sheet metal laser cutter, which has redefined the standards for metal fabrication. As the industry continues to evolve, [Company Name] remains at the forefront, empowering manufacturers with cutting-edge solutions that propel their businesses forward.With its unmatched precision, versatility, and speed, the sheet metal laser cutter by [Company Name] is set to revolutionize the metal fabrication industry, setting a new benchmark for cutting-edge technology and innovation. As the demand for high-quality and precise metal components continues to grow, manufacturers can rely on [Company Name] to deliver the advanced solutions they need to elevate their production capabilities and stay ahead of the competition.In conclusion, the new sheet metal laser cutter by [Company Name] represents a game-changing innovation that has propelled the metal fabrication industry into a new era of precision, efficiency, and productivity. With its cutting-edge technology and unparalleled capabilities, the sheet metal laser cutter is poised to revolutionize the way metal components are fabricated, setting a new standard for excellence in the industry.

Hydraulic Bending: Improving Industrial Metal Forming Techniques

Hydraulic Bending Technology Revolutionizes Company Production ProcessIn today's fast-paced manufacturing industry, efficiency and precision are the keys to success. Companies are constantly on the lookout for innovative technologies to improve their production processes and stay ahead of the competition. One such groundbreaking technology is hydraulic bending, a revolutionary method that has the potential to transform the way companies manufacture their products.Hydraulic bending is a cutting-edge bending technology that uses hydraulic force to bend metal sheets and tubes with unparalleled accuracy and efficiency. By leveraging the power of hydraulic force, this advanced technology can achieve high-precision bends while also ensuring the structural integrity of the material. This makes hydraulic bending particularly well-suited for a wide range of applications, from automotive and aerospace components to architectural and structural elements.Company, a leading manufacturer in the industrial equipment sector, is at the forefront of adopting this groundbreaking technology in its production processes. With a rich history of innovation and a commitment to embracing the latest advancements in manufacturing technology, the company is leveraging hydraulic bending to take its production capabilities to new heights.The introduction of hydraulic bending technology has enabled Company to enhance the quality and precision of its products while also streamlining its manufacturing processes. By investing in state-of-the-art hydraulic bending equipment, the company has been able to significantly reduce lead times and production costs, ultimately improving its competitive edge in the market.Company's adoption of hydraulic bending technology has also allowed it to expand its product offerings and take on more complex and demanding projects. The ability to achieve precise bends with minimal distortion has opened up new opportunities for the company to serve a wider range of industries and tackle challenging design requirements. This has not only diversified the company's portfolio but has also strengthened its position as a go-to partner for customers with specialized needs.Furthermore, the implementation of hydraulic bending technology has had a positive impact on the company's operations and workforce. By automating and streamlining the bending process, the technology has reduced the need for manual labor and repetitive tasks, allowing employees to focus on more skilled and value-added activities. This has not only improved productivity and efficiency but has also created a safer and more ergonomic working environment for the company's employees.With hydraulic bending technology, Company has been able to meet the increasing demands for precision and quality in the manufacturing industry. The technology's ability to produce complex bends with unmatched accuracy and repeatability has set a new standard for the company's products, positioning it as a trusted and reliable partner for its customers.Looking ahead, Company is committed to further harnessing the potential of hydraulic bending technology to drive innovation and growth. By continually investing in research and development, the company aims to push the boundaries of what is achievable with hydraulic bending, exploring new possibilities and applications that will further differentiate its products in the market.In conclusion, hydraulic bending technology has revolutionized Company's production process, enabling the company to deliver high-quality, precise, and cost-effective products to its customers. As the manufacturing industry continues to evolve, the company remains at the forefront of innovation, leveraging cutting-edge technologies to stay ahead of the competition and meet the ever-changing needs of its customers. With hydraulic bending, Company is shaping the future of manufacturing and setting new industry standards for quality and performance.

Top Tools and Machines for Home Improvement Projects

In today's fast-paced world, the need for efficient tools and machines is more important than ever. From manufacturing to construction, these are the tools that keep our world running smoothly and efficiently. One company that has been at the forefront of providing high-quality tools and machines is {}. With a commitment to innovation and customer satisfaction, {} has established itself as a leading provider of a wide range of tools and machines for various industries.{} has a rich history that dates back to [year], when it was founded by [founder's name]. Since then, the company has grown and expanded its product offerings to meet the evolving needs of its customers. With a focus on quality and reliability, {} has earned a reputation for excellence in the industry.One of the key factors that sets {} apart from its competitors is its dedication to research and development. The company has a team of highly skilled engineers and designers who are constantly working on developing new and improved tools and machines. This commitment to innovation has allowed {} to stay ahead of the curve and offer cutting-edge products that meet the needs of the modern world.Another strength of {} is its commitment to customer satisfaction. The company understands that each customer has unique needs and requirements, and it works closely with them to provide customized solutions. Whether it's a small business or a large corporation, {} is dedicated to meeting the needs of its customers and exceeding their expectations.In addition to its focus on innovation and customer satisfaction, {} is also committed to sustainability and environmental responsibility. The company understands the importance of reducing its carbon footprint and has implemented various initiatives to minimize its impact on the environment. From using eco-friendly materials in its products to implementing energy-efficient manufacturing processes, {} is dedicated to being a responsible corporate citizen.One of the key product lines offered by {} is its wide range of tools and machines. From power tools to heavy machinery, the company offers a comprehensive range of products to meet the diverse needs of its customers. Whether it's a small business looking for a compact and efficient tool or a large corporation in need of heavy-duty machinery, {} has the solution.The company's product line includes [list of products], each of which is designed and manufactured to the highest standards of quality and performance. With a focus on durability and reliability, {}'s products are built to withstand the rigors of daily use in a variety of industries.In conclusion, {} is a leading provider of high-quality tools and machines. With a commitment to innovation, customer satisfaction, and sustainability, the company has established itself as a trusted partner for businesses in various industries. Whether it's a small startup or a large corporation, customers can rely on {} to provide them with the tools and machines they need to succeed. As the world continues to evolve, {} will continue to be at the forefront, providing innovative solutions to meet the needs of its customers.

Top-rated Cutting Machines in China for Enhanced Precision and Efficiency

Title: Advanced Cutting Machine Technology Revolutionizes Manufacturing in ChinaIntroduction:In a breakthrough development for the manufacturing industry, a leading Chinese company has recently unveiled its highly advanced cutting machine technology. This cutting-edge innovation is set to bring significant improvements in efficiency, precision, and productivity to various industries, solidifying China's position as a global manufacturing powerhouse. With a strong commitment to innovation and a focus on meeting the evolving needs of customers, this new cutting machine is poised to revolutionize the manufacturing landscape in China and beyond.Industry-Leading Features:The cutting machine, developed by the company, incorporates several industry-leading features that make it stand out from its competitors. The removal of the brand name demonstrates the device's broader significance in the industry. This advanced machine is equipped with state-of-the-art laser cutting technology, offering unprecedented precision and speed. With its high-powered laser beam, it effortlessly cuts through various materials, including metals, plastics, and textiles, ensuring superior finish quality.Additionally, the cutting machine is powered by artificial intelligence (AI), enabling it to optimize its performance based on real-time data analysis. The integration of AI allows for adaptive cutting, where the machine can adjust its settings to the specific material being processed, greatly reducing processing time and minimizing material wastage. The company's cutting machine is also equipped with advanced sensing technology, ensuring maximum safety during operation, while maintaining optimal productivity levels.Advanced Automation Enhances Efficiency:One of the key highlights of this cutting machine is its advanced automation capabilities. By minimizing the need for human intervention, the machine streamlines production processes and significantly reduces labor costs. The automation feature ensures consistent cutting quality and eliminates errors that may occur due to human factors. This technology breakthrough empowers manufacturing plants to achieve higher production volumes while concurrently boosting overall accuracy and reliability.Moreover, the cutting machine's automation features contribute to a safer working environment for employees. With reduced exposure to potentially hazardous materials and repetitive tasks, workers can focus on more value-added activities, such as quality control and process optimization. This emphasis on worker welfare aligns with the company's commitment to social responsibility, fostering a sustainable and ethical manufacturing ecosystem.Sustainable Manufacturing and Resource Optimization:In addition to enhancing productivity and efficiency, the cutting machine also prioritizes sustainability. The adoption of this cutting-edge technology enables substantial resource optimization, reducing material waste significantly. The advanced sensors and AI-driven intelligence ensure optimal material usage, minimizing scrap and optimizing yields. By reducing overall material consumption, companies can contribute to a greener and more environmentally responsible manufacturing process.The integration of this cutting machine technology also aids in reducing energy consumption. Through sophisticated algorithms and real-time monitoring, the machine automatically adjusts its power consumption based on workload requirements, resulting in energy savings without compromising performance. This energy efficiency not only reduces operating costs but also helps in minimizing carbon footprint, contributing to the sustainable development goals of both the company and the industry.Conclusion:The introduction of this cutting machine technology marks a significant milestone in the manufacturing industry in China. The removal of the brand name in this news article highlights the broader implications of this breakthrough innovation. With its state-of-the-art features, including enhanced precision, automation, and sustainability, the cutting machine is set to transform manufacturing processes, catapulting China's industrial growth even further. By embracing and investing in cutting-edge technologies, China solidifies its position as a leader in the manufacturing sector, ready to meet the future challenges and demands of the global market.

Powerful 100w Co2 Laser: Everything You Need to Know

Recently, the engineering industry has witnessed a groundbreaking achievement with the introduction of the state-of-the-art 100w CO2 Laser by a leading manufacturing company. This cutting-edge technology offers a wide range of applications in various industries, including automotive, aerospace, medical, and electronics.The 100w CO2 Laser is designed to provide high precision and efficiency in material processing tasks, such as cutting, engraving, and marking. With its advanced capabilities, this cutting-edge technology is set to revolutionize the way industrial materials are processed, offering unmatched precision and speed.The company behind this innovative technology has a proven track record in delivering high-quality industrial solutions. With decades of experience and expertise in manufacturing advanced machinery, they have established themselves as a leading force in the engineering industry. The introduction of the 100w CO2 Laser is a testament to their commitment to driving innovation and providing their customers with cutting-edge solutions.One of the key features of the 100w CO2 Laser is its high power output, which enables faster and more efficient material processing. This makes it ideal for a wide range of applications, from cutting and engraving metals to marking plastics and ceramics. Its versatility and precision make it a valuable tool for manufacturers looking to streamline their production processes and achieve superior results.In addition to its power and precision, the 100w CO2 Laser also boasts advanced control systems and user-friendly interfaces, making it easy to operate and integrate into existing production lines. This ensures that manufacturers can maximize the potential of this technology without the need for extensive training or retooling.Furthermore, the 100w CO2 Laser is designed with sustainability in mind, featuring energy-efficient components that minimize power consumption and reduce environmental impact. This makes it an environmentally friendly option for manufacturers looking to optimize their production processes while minimizing their carbon footprint.The introduction of the 100w CO2 Laser represents a significant leap forward in the field of material processing technology. With its advanced capabilities, precision, and sustainability, it promises to revolutionize the way manufacturers approach material processing tasks, offering unprecedented levels of efficiency and quality.The company's commitment to innovation and excellence is reflected in the development of this cutting-edge technology, and they are set to continue pushing the boundaries of what is possible in the engineering industry.In conclusion, the introduction of the 100w CO2 Laser by this leading manufacturing company represents a significant milestone in the field of material processing technology. With its advanced capabilities and sustainable design, it is set to redefine the way manufacturers approach material processing tasks, offering unmatched precision, efficiency, and quality. As the engineering industry continues to evolve, the 100w CO2 Laser stands as a testament to the power of innovation and the possibilities that lie ahead.