Top Tube Laser Cutting Equipment for Precision Fabrication

By:Admin

{Company Name} is a renowned manufacturer of industrial machinery, specializing in laser cutting and metal fabrication equipment. With decades of experience and a commitment to innovation, the company has continuously invested in research and development to bring cutting-edge solutions to the market.

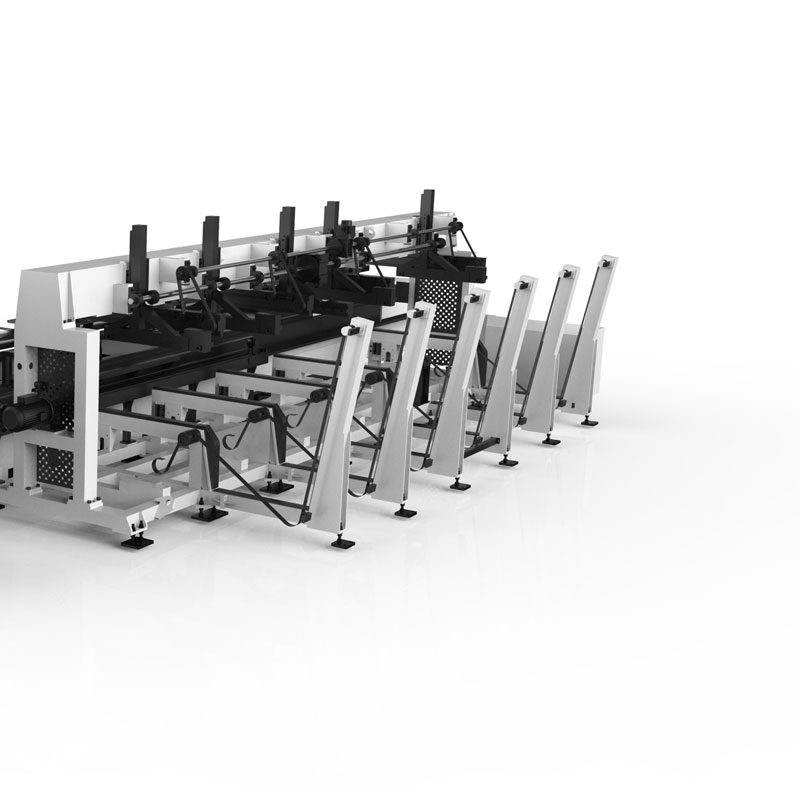

The tube laser cutting equipment offered by {Company Name} is equipped with the latest technological advancements, allowing for the processing of a wide range of tube profiles including round, square, rectangular, and oval tubes. The equipment utilizes fiber laser technology, which delivers exceptional cutting quality while maintaining high productivity. This results in clean, precise cuts with minimal heat-affected zones, ensuring the integrity of the material is preserved.

One of the key advantages of {Company Name}'s tube laser cutting equipment is its versatility. The equipment is capable of handling a variety of materials including carbon steel, stainless steel, aluminum, and other non-ferrous metals. This versatility makes it an ideal solution for industries such as automotive, aerospace, construction, and general manufacturing.

In addition to its cutting capabilities, {Company Name}'s tube laser cutting equipment is also equipped with advanced automation features. This includes automatic loading and unloading systems, as well as real-time monitoring and control software. These features not only improve efficiency but also ensure consistent and accurate results, reducing the need for manual intervention and minimizing the risk of errors.

Furthermore, {Company Name} takes pride in providing comprehensive support to its customers. From installation and training to maintenance and technical support, the company is dedicated to ensuring the success of its clients. This commitment to customer satisfaction has earned {Company Name} a reputation for reliability and excellence in the industry.

The impact of {Company Name}'s tube laser cutting equipment can be observed in the testimonials of its customers. Many have reported significant improvements in productivity, material utilization, and overall quality of their fabricated products. This has enabled them to stay ahead of the competition and meet the increasing demands of their customers.

Looking ahead, {Company Name} is committed to further advancing its tube laser cutting technology. With a focus on continuous improvement, the company aims to integrate more cutting-edge features and functionalities into its equipment, further enhancing its performance and capabilities.

In conclusion, {Company Name}'s tube laser cutting equipment has set a new standard for precision and efficiency in the manufacturing industry. With its advanced technology, versatility, and comprehensive support, the company has solidified its position as a leader in the market. As the demand for high-quality fabricated metal products continues to grow, {Company Name} remains at the forefront, providing innovative solutions to meet the evolving needs of the industry.

Company News & Blog

Top Cutting and Bending Machine: A Complete Guide

Cutting and Bending Machine revolutionizes metalworking industryThe metalworking industry has taken a significant leap forward with the introduction of the cutting and bending machine by a leading manufacturing company. This innovative machine is designed to streamline the metal fabrication process and improve efficiency in a wide range of applications.The cutting and bending machine is capable of precisely cutting and shaping various types of metal, including steel, aluminum, and copper. Its advanced technology and precision-engineered components enable it to deliver accurate and consistent results, making it a valuable asset for manufacturers and fabricators.The machine's cutting capabilities are especially impressive, as it is able to cut through thick metal sheets with ease and precision. This is particularly beneficial for industries that require intricate and complex metal components, such as the aerospace and automotive sectors. In addition, the machine's bending capabilities allow for the creation of custom metal shapes and structures, offering endless possibilities for creative and innovative designs.One of the key features of this cutting and bending machine is its user-friendly interface, which makes it easy to operate and adjust for different applications. This intuitive interface, combined with the machine's high-speed performance, allows for increased productivity and reduced downtime, leading to cost savings for manufacturers.Furthermore, the cutting and bending machine is equipped with advanced safety features to ensure the well-being of operators and prevent accidents in the workplace. This includes protective barriers and emergency stop buttons, as well as automatic shut-off mechanisms in case of a malfunction.The company behind this cutting and bending machine is a renowned leader in the manufacturing industry, with a long-standing reputation for delivering high-quality and reliable machinery. With a commitment to innovation and customer satisfaction, the company has continuously invested in research and development to create cutting-edge solutions for the metalworking industry.In addition to the cutting and bending machine, the company offers a comprehensive range of metal fabrication equipment and services, including laser cutting machines, press brakes, and welding systems. This full suite of products and expertise enables the company to provide end-to-end solutions for its clients, from design and prototyping to production and assembly.The company's dedication to excellence is further demonstrated through its emphasis on customer support and after-sales service. With a team of experienced technicians and engineers, the company offers training, maintenance, and technical assistance to ensure that its clients maximize the potential of their equipment and achieve optimal results.As a testament to its commitment to quality and innovation, the company has received numerous accolades and certifications for its products and services. This includes ISO 9001 certification for its quality management system, as well as industry awards for its cutting-edge machinery and technological advancements.In light of the growing demand for efficient and reliable metal fabrication solutions, the cutting and bending machine is set to make a significant impact on the industry. Its ability to deliver precise and high-quality results, combined with the expertise and support provided by the manufacturing company, positions it as a game-changer for manufacturers and fabricators seeking to stay ahead in a competitive market.Overall, the cutting and bending machine represents a new era in metalworking, offering unprecedented capabilities and efficiency for a wide range of applications. With its innovative technology, user-friendly interface, and comprehensive support, it is poised to redefine the standards of metal fabrication and set new benchmarks for the industry as a whole.

Top Tools and Machines for Home Improvement Projects

In today's fast-paced world, the need for efficient tools and machines is more important than ever. From manufacturing to construction, these are the tools that keep our world running smoothly and efficiently. One company that has been at the forefront of providing high-quality tools and machines is {}. With a commitment to innovation and customer satisfaction, {} has established itself as a leading provider of a wide range of tools and machines for various industries.{} has a rich history that dates back to [year], when it was founded by [founder's name]. Since then, the company has grown and expanded its product offerings to meet the evolving needs of its customers. With a focus on quality and reliability, {} has earned a reputation for excellence in the industry.One of the key factors that sets {} apart from its competitors is its dedication to research and development. The company has a team of highly skilled engineers and designers who are constantly working on developing new and improved tools and machines. This commitment to innovation has allowed {} to stay ahead of the curve and offer cutting-edge products that meet the needs of the modern world.Another strength of {} is its commitment to customer satisfaction. The company understands that each customer has unique needs and requirements, and it works closely with them to provide customized solutions. Whether it's a small business or a large corporation, {} is dedicated to meeting the needs of its customers and exceeding their expectations.In addition to its focus on innovation and customer satisfaction, {} is also committed to sustainability and environmental responsibility. The company understands the importance of reducing its carbon footprint and has implemented various initiatives to minimize its impact on the environment. From using eco-friendly materials in its products to implementing energy-efficient manufacturing processes, {} is dedicated to being a responsible corporate citizen.One of the key product lines offered by {} is its wide range of tools and machines. From power tools to heavy machinery, the company offers a comprehensive range of products to meet the diverse needs of its customers. Whether it's a small business looking for a compact and efficient tool or a large corporation in need of heavy-duty machinery, {} has the solution.The company's product line includes [list of products], each of which is designed and manufactured to the highest standards of quality and performance. With a focus on durability and reliability, {}'s products are built to withstand the rigors of daily use in a variety of industries.In conclusion, {} is a leading provider of high-quality tools and machines. With a commitment to innovation, customer satisfaction, and sustainability, the company has established itself as a trusted partner for businesses in various industries. Whether it's a small startup or a large corporation, customers can rely on {} to provide them with the tools and machines they need to succeed. As the world continues to evolve, {} will continue to be at the forefront, providing innovative solutions to meet the needs of its customers.

Hydraulic Bending: Improving Industrial Metal Forming Techniques

Hydraulic Bending Technology Revolutionizes Company Production ProcessIn today's fast-paced manufacturing industry, efficiency and precision are the keys to success. Companies are constantly on the lookout for innovative technologies to improve their production processes and stay ahead of the competition. One such groundbreaking technology is hydraulic bending, a revolutionary method that has the potential to transform the way companies manufacture their products.Hydraulic bending is a cutting-edge bending technology that uses hydraulic force to bend metal sheets and tubes with unparalleled accuracy and efficiency. By leveraging the power of hydraulic force, this advanced technology can achieve high-precision bends while also ensuring the structural integrity of the material. This makes hydraulic bending particularly well-suited for a wide range of applications, from automotive and aerospace components to architectural and structural elements.Company, a leading manufacturer in the industrial equipment sector, is at the forefront of adopting this groundbreaking technology in its production processes. With a rich history of innovation and a commitment to embracing the latest advancements in manufacturing technology, the company is leveraging hydraulic bending to take its production capabilities to new heights.The introduction of hydraulic bending technology has enabled Company to enhance the quality and precision of its products while also streamlining its manufacturing processes. By investing in state-of-the-art hydraulic bending equipment, the company has been able to significantly reduce lead times and production costs, ultimately improving its competitive edge in the market.Company's adoption of hydraulic bending technology has also allowed it to expand its product offerings and take on more complex and demanding projects. The ability to achieve precise bends with minimal distortion has opened up new opportunities for the company to serve a wider range of industries and tackle challenging design requirements. This has not only diversified the company's portfolio but has also strengthened its position as a go-to partner for customers with specialized needs.Furthermore, the implementation of hydraulic bending technology has had a positive impact on the company's operations and workforce. By automating and streamlining the bending process, the technology has reduced the need for manual labor and repetitive tasks, allowing employees to focus on more skilled and value-added activities. This has not only improved productivity and efficiency but has also created a safer and more ergonomic working environment for the company's employees.With hydraulic bending technology, Company has been able to meet the increasing demands for precision and quality in the manufacturing industry. The technology's ability to produce complex bends with unmatched accuracy and repeatability has set a new standard for the company's products, positioning it as a trusted and reliable partner for its customers.Looking ahead, Company is committed to further harnessing the potential of hydraulic bending technology to drive innovation and growth. By continually investing in research and development, the company aims to push the boundaries of what is achievable with hydraulic bending, exploring new possibilities and applications that will further differentiate its products in the market.In conclusion, hydraulic bending technology has revolutionized Company's production process, enabling the company to deliver high-quality, precise, and cost-effective products to its customers. As the manufacturing industry continues to evolve, the company remains at the forefront of innovation, leveraging cutting-edge technologies to stay ahead of the competition and meet the ever-changing needs of its customers. With hydraulic bending, Company is shaping the future of manufacturing and setting new industry standards for quality and performance.

Gain Insights into Laser Welding Technology

IntroductionLaser welding is a quick and efficient way of joining two pieces of metal together using intense, focused beams of light. In recent years, developments in laser technology have made handheld laser welding machine a popular tool for a range of industrial applications. In this article, we will explore the benefits of handheld laser welding machines and discuss some of the key factors to consider when selecting one for your business.What is a Handheld Laser Welding Machine?A handheld laser welding machine is a portable device that allows welders to perform laser welding tasks in remote or hard-to-reach locations. It typically consists of a compact laser source, a control unit, and a handheld welding gun or probe. The laser source generates a high-energy beam of light that is focused onto the material being welded using a series of lenses and mirrors. The welding gun or probe is used to direct the laser beam onto the target area, allowing the welder to create a smooth, precise weld.Benefits of Handheld Laser Welding MachinesHandheld laser welding machines offer a number of advantages over traditional welding methods:1. Speed and Efficiency: Laser welding is a fast and highly efficient technique that can produce high-quality welds in a fraction of the time it takes to perform manual welding. Handheld laser welding machines make it possible to complete welding tasks quickly and easily, even in remote or hard-to-reach areas.2. Precision and Accuracy: Laser welding is a precise technique that allows welders to create high-quality, defect-free welds with minimal distortion. Handheld laser welding machines offer exceptional accuracy and precision, making them ideal for complex welding tasks that require fine control over the weld area.3. Cost-effectiveness: While handheld laser welding machines are more expensive than traditional welding equipment, they can offer significant cost savings over time. Laser welding requires less material, produces less waste, and requires fewer post-welding treatments than traditional welding methods, which can help to reduce costs over the long term.Key Factors to Consider When Choosing a Handheld Laser Welding MachineWhen selecting a handheld laser welding machine, there are several key factors to consider:1. Power: Handheld laser welding machines are available in a range of power levels, from low-power machines designed for delicate welding tasks to high-power machines capable of welding thick materials. Consider the materials you will be welding when selecting a machine with an appropriate power level.2. Beam Quality: The quality of the laser beam can affect the quality of the weld. Look for a machine that produces a stable, collimated beam with consistent intensity.3. Ergonomics: Handheld laser welding machines should be lightweight and easy to handle for extended periods of time. Look for machines with comfortable grips and ergonomic designs.4. Maintenance: Like all welding equipment, handheld laser welding machines require regular maintenance to ensure optimal performance. Look for machines with user-friendly maintenance routines and easy-to-replace components.ConclusionHandheld laser welding machines offer a range of benefits for industrial applications, including speed, efficiency, precision, and cost-effectiveness. When selecting a machine, consider the power and beam quality of the laser, as well as the ergonomics and maintenance needs of the machine. With the right handheld laser welding machine, you can complete welding tasks quickly and easily, even in remote or hard-to-reach areas.

How Fiber Laser Cutting Systems Are Improving Manufacturing Processes

Fiber Laser Cutting Systems are revolutionizing the metal cutting industry with their precision, speed, and efficiency. One of the leading manufacturers of these cutting-edge machines is {Company X}, a global leader in advanced manufacturing technology. With a strong focus on innovation and customer satisfaction, {Company X} has been at the forefront of the industry for over two decades.The {Company X} Fiber Laser Cutting Systems are equipped with state-of-the-art technology that allows for fast and accurate cutting of a wide range of materials, including stainless steel, aluminum, copper, and titanium. These cutting systems are designed to meet the needs of various industries, from automotive and aerospace to medical and consumer electronics.One of the key features of {Company X} Fiber Laser Cutting Systems is their high precision, which is made possible by advanced motion control systems and intelligent software. This level of precision ensures that the finished parts meet the strictest quality standards, making them ideal for use in the most demanding applications.In addition to precision, {Company X} Fiber Laser Cutting Systems are known for their speed and efficiency. With high-powered laser sources and high-speed cutting heads, these machines can quickly and accurately cut complex shapes and intricate patterns, reducing production time and increasing overall productivity.Furthermore, {Company X} offers a range of Fiber Laser Cutting Systems to suit different production needs, from small, compact machines for smaller workshops to large, automated systems for high-volume production facilities. This flexibility makes {Company X} a preferred choice for businesses of all sizes, seeking to enhance their metal cutting capabilities.{Company X} not only provides cutting-edge machines but also offers comprehensive support and services to ensure that their customers get the most out of their investment. This includes training programs, maintenance services, and technical support, all aimed at keeping the Fiber Laser Cutting Systems running at peak performance.With a strong commitment to research and development, {Company X} is constantly pushing the boundaries of what is possible with Fiber Laser Cutting technology. Their team of engineers and technicians are always working on new innovations and improvements to further enhance the capabilities of their cutting systems, staying ahead of the curve and setting new industry standards.Through strategic partnerships and collaborations with other industry leaders, {Company X} continues to drive the advancement of Fiber Laser Cutting technology, ensuring that their customers have access to the latest and most advanced solutions for their metal cutting needs.In conclusion, {Company X} Fiber Laser Cutting Systems are setting new benchmarks in the metal cutting industry, providing unmatched precision, speed, and efficiency to a wide range of businesses. With a strong focus on innovation, customer satisfaction, and comprehensive support, {Company X} remains a trusted partner for those seeking to elevate their metal cutting capabilities. As the demand for high-quality, precision-cut parts continues to grow across various industries, {Company X} is well-positioned to meet and exceed these demands with their cutting-edge technology and unwavering commitment to excellence.

High Precision and Speed: Discover the Ultimate Fiber Laser Cutting Machine Technology for Metal Cutting

and Precision in Metal Fabrication Industry.Fiber Laser Cutting Speed and Precision in Metal Fabrication IndustryIn metal fabrication, cutting precision and speed are two essential factors that can make or break a project. Traditionally, metal cutting was done manually with saws, drills, and other handheld tools. This method was labor-intensive, time-consuming, and prone to errors. However, with the emergence of technology, metal cutting has become more efficient, accurate, and faster. Fiber laser cutting machines have revolutionized the metal fabrication industry by providing a reliable and cost-effective solution for cutting and punching various metal materials.Fiber laser cutting machines are designed to cut metals such as stainless steel, aluminum, copper, brass, and others. They work by focusing a high-powered laser beam on the metal material to produce a clean, precise, and quality cut. The laser beam is transmitted through a fiber optic cable, unlike traditional lasers that use mirrors. This technology offers several benefits such as higher accuracy, faster cutting speeds, reduced operating costs, and improved reliability.One of the most significant advantages of fiber laser cutting machines is their cutting precision. They can cut metal materials with high accuracy levels up to 0.01mm, producing clean, burr-free edges. This level of precision ensures that the finished product meets the required specifications, reducing the need for further processing. Additionally, fiber laser cutting machines can cut complex shapes and patterns, making them ideal for producing intricate metal parts and components.Fiber laser cutting machines are also renowned for their cutting speed. Unlike traditional cutting methods that rely on physical force, fiber laser cutting machines use a high-powered laser beam that cuts through the metal material quickly and efficiently. This results in faster cutting speeds, reducing production time and costs. Additionally, fiber laser cutting machines can achieve cutting speeds of up to 100 meters per minute, making them ideal for cutting large volumes of metal materials.Fiber laser cutting machines offer a range of cutting advantages that increase productivity, quality, and efficiency. They are designed to meet the demands of modern metal fabrication, providing manufacturers with a reliable and cost-effective solution for their cutting needs. Choosing the right fiber laser cutting machine depends on several factors, such as the type and thickness of the metal material, the required cutting speed, the level of precision required, and the size of the metal material.In conclusion, fiber laser cutting machines offer superior cutting precision and speed that is unmatched by traditional metal cutting methods. They provide a cost-effective and reliable solution for metal fabrication, improving productivity, efficiency, and quality. Fiber laser cutting technology represents the future of metal cutting and will continue to transform the metal fabrication industry. If you're looking for high-quality metal cutting services, consider fiber laser cutting machines for a precise and efficient cutting process.

Top 3D Fiber Laser Technology: A Breakthrough in Laser Cutting and Engraving

The demand for advanced technology in the manufacturing industry continues to grow, and one company at the forefront of innovation is {Company Name}. Known for their cutting-edge solutions, {Company Name} has recently introduced the latest addition to their product line - the 3D Fiber Laser.The 3D Fiber Laser is a powerful and versatile tool that is set to revolutionize the way manufacturers approach cutting, welding, and engraving processes. With its state-of-the-art technology, this machine is capable of meeting the high demands of modern production environments, while also providing the precision and efficiency needed to drive productivity.The key features of the 3D Fiber Laser include its high-speed cutting capabilities, which allow for quick and accurate processing of various materials. Whether working with metals, plastics, or composites, the machine is designed to deliver superior results with minimal waste. Additionally, its advanced laser technology enables it to perform complex, intricate cuts with ease, making it an ideal choice for industries that require precise detailing and intricate designs.One of the standout features of the 3D Fiber Laser is its ability to work with a wide range of materials and thicknesses, making it a versatile solution for manufacturers across different sectors. This flexibility allows for increased production efficiency, as the machine can adapt to the specific needs of various applications without compromising on quality or speed.In addition to its cutting capabilities, the 3D Fiber Laser also offers advanced welding and engraving functionalities. Its advanced welding technology is designed to deliver strong, reliable bonds with minimal heat distortion, ensuring that the integrity of the materials remains uncompromised. This makes it an excellent choice for applications that require durable, high-quality welds, such as in the automotive and aerospace industries.Furthermore, its engraving capabilities allow for the creation of detailed, intricate designs on a wide range of materials, opening up new possibilities for customization and personalization in manufacturing processes. This feature is particularly valuable for industries that require branding, serialization, or unique markings on their products.{Company Name} is dedicated to providing cutting-edge solutions to meet the evolving needs of the manufacturing industry. With a strong commitment to innovation and customer satisfaction, the company's 3D Fiber Laser is set to redefine the standards for precision and efficiency in manufacturing processes."We are excited to introduce the 3D Fiber Laser to the market," said {Company Name}'s CEO. "This machine represents the culmination of years of research and development, and we believe it has the potential to transform the way manufacturers approach cutting, welding, and engraving processes. With its advanced technology and versatile capabilities, we are confident that it will set a new standard for efficiency and precision in manufacturing."As the manufacturing industry continues to evolve, the demand for advanced, high-tech solutions is only expected to grow. {Company Name}'s introduction of the 3D Fiber Laser is a testament to their commitment to staying ahead of the curve and providing customers with the most innovative tools to support their manufacturing needs.With its cutting-edge technology, versatile capabilities, and dedication to quality, the 3D Fiber Laser is poised to make a significant impact in the manufacturing industry. As companies strive to meet the demands of modern production environments, this machine offers a powerful solution that is designed to drive efficiency, precision, and productivity in manufacturing processes.

The Top Fiber Laser Source for Optimal Performance

Best Fiber Laser Source Offers Superior Quality and PerformanceFiber lasers are a revolutionary technology in the manufacturing industry, offering a reliable and efficient alternative to traditional laser sources. With their advanced features and superior performance, fiber lasers have become a popular choice for a wide range of applications, including cutting, welding, marking, and engraving.One of the leading providers of fiber laser sources is {Company}. With a strong focus on innovation and quality, {Company} has established itself as a trusted name in the industry, offering cutting-edge fiber laser solutions to meet the diverse needs of its customers.{Company} offers a wide range of fiber laser sources, including high-power lasers for industrial cutting and welding applications, as well as compact and versatile lasers for marking and engraving. The company's fiber lasers are known for their exceptional beam quality, high efficiency, and reliability, making them a preferred choice for manufacturers looking to enhance their production processes.One of the key advantages of {Company}'s fiber laser sources is their high beam quality, which enables precise and clean cutting and welding results. This is especially important for industries such as automotive, aerospace, and electronics, where the quality of the finished products is of utmost importance. By using {Company}'s fiber lasers, manufacturers can achieve superior edge quality, tight tolerances, and minimal heat-affected zones, leading to higher productivity and cost savings.In addition to their superior performance, {Company}'s fiber laser sources are also designed for ease of integration and operation. The company offers a range of fiber lasers with different power levels, wavelengths, and processing capabilities, allowing customers to choose the most suitable solution for their specific requirements. Whether it's a standalone laser system or an integrated solution for automated production lines, {Company} can provide tailored fiber laser solutions to meet the unique needs of its clients.Furthermore, {Company}'s commitment to quality and reliability is evident in its rigorous testing and quality control processes. Each fiber laser source undergoes thorough inspection and testing to ensure consistent performance and long-term durability. This level of quality assurance gives customers peace of mind, knowing that they are investing in a reliable and long-lasting laser solution.{Company} also takes pride in its customer-centric approach, providing comprehensive technical support, training, and maintenance services to ensure the smooth operation of its fiber laser sources. The company's team of experts is dedicated to helping customers optimize their laser processing applications, improve productivity, and maximize the value of their investment in {Company}'s fiber laser solutions.As the demand for high-performance laser processing solutions continues to grow, {Company} remains at the forefront of innovation, continuously improving and expanding its range of fiber laser sources. With a focus on quality, performance, and customer satisfaction, {Company} is well-positioned to meet the evolving needs of the manufacturing industry and drive the adoption of fiber laser technology across various sectors.In conclusion, {Company} stands out as a reliable and trusted provider of best-in-class fiber laser sources, offering superior quality, performance, and support to its customers. By choosing {Company}'s fiber lasers, manufacturers can achieve exceptional results in cutting, welding, marking, and engraving, ultimately enhancing their production processes and staying ahead of the competition.

Laser Cutting of Hardox Steel News Highlights Its Potential

Title: Advanced Laser Cutting Techniques Revolutionizing Metal Fabrication IndustryIntroduction:Metal fabrication has been an integral part of various industries, from automotive to construction, for decades. As technological advancements continue to reshape the manufacturing landscape, companies are constantly seeking innovative solutions to enhance their production capabilities. Among these groundbreaking technologies, Hardox Laser Cutting has emerged as a game-changer, delivering unparalleled precision and efficiency in metal fabrication.In today's fast-paced world, where timelines and quality are crucial, Hardox Laser Cutting enables manufacturers to meet and surpass industry standards. By eliminating traditional cutting methods and embracing the power of laser technology, companies can now achieve exceptional accuracy, reduced lead times, and enhanced production efficiency – leading to improved overall performance.Benefits of Hardox Laser Cutting:1. Unmatched Precision:Hardox Laser Cutting utilizes high-powered lasers to accurately cut intricate designs and shapes in various grades of metal. The process eliminates the possibility of human error, ensuring precise and intricate cuts, resulting in perfectly fit components. This meticulous cutting accuracy eliminates the need for rework, reducing production costs for manufacturers.2. Enhanced Productivity:The introduction of Hardox Laser Cutting in metal fabrication processes has significantly increased productivity for companies. The speed at which the lasers can cut through metal surpasses traditional cutting methods, enabling faster production cycles. Manufacturers can now deliver products to market more rapidly, giving them a competitive edge in the industry.3. Versatility:Hardox Laser Cutting demonstrates remarkable versatility as it can be used on a wide range of metals, including stainless steel, aluminum, and various grades of carbon steel. With the ability to accommodate various thicknesses, this technology presents endless possibilities for manufacturers across different sectors. Whether it is cutting precise components for aeronautics or constructing intricate architectural designs, Hardox Laser Cutting is a reliable partner.4. Material Conservation:Traditional cutting methods often result in a significant loss of material due to imprecise cuts and inaccuracies. Hardox Laser Cutting tackles this issue head-on by minimizing wastage through its precise and precise cutting process. This material conservation not only reduces costs for manufacturers but also contributes to sustainable practices, aligning with global efforts toward environmental responsibility.5. Cost-Effective Solution:Hardox Laser Cutting offers a cost-effective solution for metal fabricators. With increased productivity, reduced labor costs, and minimized material waste, manufacturers can amplify their profitability. By optimizing production processes, businesses can allocate resources more effectively and enhance their return on investment.Conclusion:Hardox Laser Cutting has emerged as a transformative technology, revolutionizing the metal fabrication industry. As manufacturers strive to meet the demands of an ever-evolving market, this advanced cutting technique proves to be indispensable. With its unmatched precision, improved productivity, versatility, material conservation, and cost-effective benefits, companies can now elevate their metal fabrication processes to new heights. With Hardox Laser Cutting as a reliable ally, we can expect businesses to thrive in the competitive landscape with superior quality products and timely deliveries.

High-Quality Co2 Laser Cutters Now Available for Purchase

Are you in the market for a top-of-the-line CO2 laser cutter? Look no further than the latest offering from [Company Name]! With their cutting-edge technology and years of experience in the industry, [Company Name] is proud to present their high-quality CO2 laser cutter for sale, designed to meet the needs of professionals in a wide range of industries.The [Company Name] CO2 laser cutter is equipped with a powerful laser that is capable of cutting through various materials with precision and speed. Whether you're working with wood, acrylic, glass, leather, or other materials, this state-of-the-art machine is designed to deliver exceptional results.One of the key features of the [Company Name] CO2 laser cutter is its advanced control system, which allows for precise and accurate cutting. This means that you can create intricate designs and achieve the exact specifications you need for your projects. The machine also comes with a user-friendly interface, making it easy to operate for both experienced professionals and those who are new to laser cutting technology.In addition to its cutting capabilities, the [Company Name] CO2 laser cutter also offers engraving and marking functions, further expanding its utility. This makes it a versatile tool for a wide range of applications, from creating custom signage and promotional items to producing intricate art pieces and architectural models.With [Company Name]'s commitment to quality and customer satisfaction, you can trust that their CO2 laser cutter is built to the highest standards. The machine is constructed with durable materials and is designed to withstand the rigors of regular use, ensuring that it will deliver reliable performance for years to come.As a well-established company in the industry, [Company Name] has a reputation for providing excellent customer service and technical support. When you purchase their CO2 laser cutter, you can expect comprehensive training and assistance to help you get the most out of the machine. Their team of experts is available to answer any questions you may have and provide guidance on how to optimize the use of the equipment for your specific needs.In addition to their outstanding product, [Company Name] also offers a range of accessories and consumables to complement the CO2 laser cutter, including different types of lenses, cutting heads, and other essential components. This ensures that you have everything you need to keep your machine running at its best and to explore its full potential.Whether you're a small business looking to expand your capabilities or a large-scale manufacturer seeking to improve efficiency, the [Company Name] CO2 laser cutter is an excellent investment that can help take your operations to the next level. With its precision, speed, and versatility, this machine is designed to enhance your productivity and deliver exceptional results for a wide variety of projects.In conclusion, the new CO2 laser cutter from [Company Name] is a game-changer in the industry. With its advanced technology, precision cutting capabilities, and reliable performance, this machine is a valuable asset for professionals across different fields. When you invest in the [Company Name] CO2 laser cutter, you're not just purchasing a piece of equipment – you're gaining a powerful tool that can help you achieve your creative and professional goals. With its exceptional quality and comprehensive support, this machine is the perfect choice for anyone looking to elevate their cutting and engraving capabilities. Contact [Company Name] today to learn more about their CO2 laser cutter for sale and take your projects to new heights.