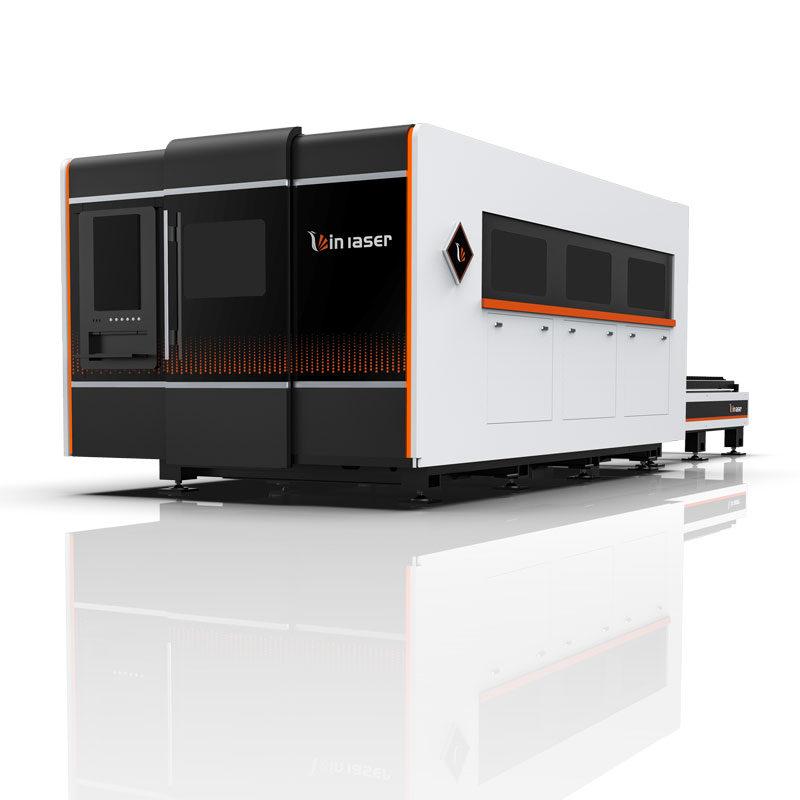

No programming or teaching required, simple to operate. No deformation of the welding seam, fast welding speed and no consumables.

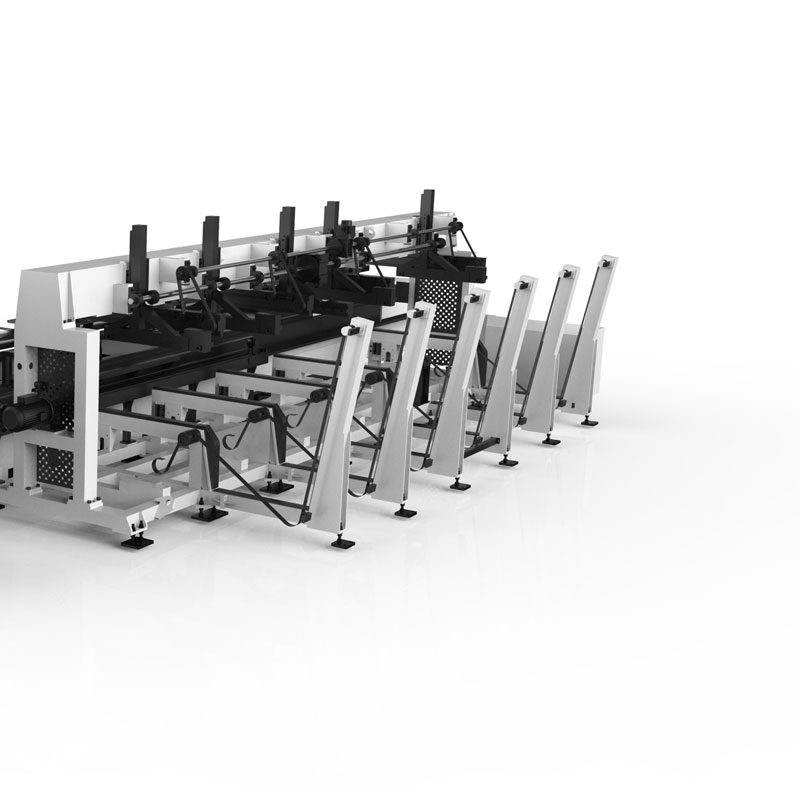

Laser welding is a processing method that uses a high energy density laser beam as a heat source to weld materials.In recent years, due to the continuous development of materials, technologies and processes, lasers have been widely used in the welding and brazing of plastics, metals, etc., and will continue to replace traditional welding methods such as argon arc welding in the automotive, sensor, electronics and other industries. The laser of the handheld laser welding machine with handheld welding head, similar to argon arc welding, flexible and simple operation, suitable for the orders which are small or large batches and for product consistency requirements are not very high.It can be widely used in complex and irregular welding processes in kitchen and bathroom cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture and other industries.

The weld is delicate, strong and fast. Welding speed is 3-10 times faster than conventional argon arc welding and plasma welding. Cost saving, stable and easy.

Mainly used for welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, overlay welding, etc., with small welding seam width and small heat-affected zone, which will not lead to deformation of the workpiece, traces on the back side, etc., without processing or simple processing after welding.