Efficient Laser Cutter for Steel Plate Cutting: A Game Changer in Metal Fabrication

By:Admin

The manufacturing industry has always been at the forefront of innovation and technological advancements, and the latest breakthrough in laser cutting technology is no exception. With the introduction of the new {Company Name}'s advanced laser cutter, steel plate fabrication has been completely revolutionized, setting a new standard in precision, efficiency, and quality.

{Company Name} has been a leader in the industrial manufacturing sector for over 20 years, specializing in cutting-edge fabrication tools and solutions for a wide range of industries. Their dedication to research and development has led to the creation of the most advanced laser cutting technology available on the market today. The new laser cutter is capable of handling steel plates of varying thicknesses with unprecedented accuracy and speed, making it an invaluable asset for any manufacturing operation.

One of the key features of {Company Name}'s laser cutter is its ability to achieve extremely precise cuts, resulting in minimal material waste and maximum efficiency. This level of accuracy is essential in modern fabrication processes, where the demand for high-quality, precision-cut components is greater than ever. Additionally, the laser cutter's high-speed capabilities allow for rapid production turnaround times, giving manufacturers a competitive edge in meeting tight deadlines and fulfilling customer orders promptly.

Furthermore, the advanced technology utilized in {Company Name}'s laser cutter ensures a superior cut quality, free of burrs and other imperfections commonly associated with traditional cutting methods. This not only enhances the overall aesthetics of the fabricated steel plates but also eliminates the need for additional finishing processes, saving both time and resources for manufacturers.

In addition to its unparalleled precision and speed, the laser cutter is also equipped with state-of-the-art safety features and user-friendly controls, ensuring a safe and seamless operation for the machine operator. This emphasis on safety and usability reflects {Company Name}'s commitment to providing cutting-edge solutions that not only improve productivity but also prioritize the well-being of the individuals operating the equipment.

The impact of {Company Name}'s revolutionary laser cutting technology on the manufacturing industry cannot be overstated. By streamlining the steel plate fabrication process and enhancing the overall quality of the end product, manufacturers are poised to experience significant cost savings and operational efficiencies. Moreover, the ability to meet the increasingly stringent demands of modern fabrication projects positions companies at the forefront of market competition, ensuring their continued success and growth.

As the global manufacturing landscape continues to evolve, innovative solutions such as {Company Name}'s advanced laser cutter are essential for businesses to remain competitive and stay ahead of industry trends. With its unparalleled precision, speed, and quality, the new laser cutter has set a new standard for steel plate fabrication, cementing {Company Name}'s reputation as a trailblazer in the manufacturing sector.

In conclusion, {Company Name}'s cutting-edge laser cutter represents a groundbreaking advancement in steel plate fabrication technology. By delivering unparalleled precision, efficiency, and quality, this innovative solution is poised to transform the manufacturing industry and empower businesses to thrive in today's competitive market. With a proven track record of excellence and a commitment to driving progress, {Company Name} continues to lead the way in providing advanced tools and solutions for the global manufacturing community.

Company News & Blog

Top-notch Laser Cutting Services for All Your Cutting Needs

Title: Leading Laser Cutting Service Provider Revolutionizes Precision FabricationIntroduction:In today's rapidly evolving manufacturing landscape, precision and efficiency are the driving forces behind successful businesses. One company at the forefront of this revolution is Best Laser Cutting Service (BLCS), an industry leader in delivering exceptional laser-cutting solutions. BLCS stands out from the competition with its commitment to state-of-the-art technology, unparalleled expertise, and unyielding dedication to customer satisfaction. With a diverse range of applications and a reputation for excellence, BLCS is transforming the field of precision fabrication.Overview of Best Laser Cutting Service:BLCS, a prominent player in the laser-cutting industry, has been instrumental in delivering cutting-edge solutions for a variety of sectors. With years of experience, the company's team of experts harnesses the power of advanced laser technology to meet the unique requirements of clients. From intricate metal designs to complex fabrication tasks, BLCS offers a comprehensive range of services that consistently meet the highest industry standards.Advanced Laser Technology:BLCS prides itself on staying ahead of the curve when it comes to technology. The company utilizes cutting-edge laser cutting machines, equipped with high-strength lasers capable of delivering precise and intricate cuts. By incorporating the latest in laser technology, BLCS ensures superior accuracy, faster turnaround times, and increased productivity for clients across industries.Diverse Applications:With a deep understanding of various industries, BLCS caters to a wide spectrum of clients. The company offers laser-cutting services for metals such as steel, aluminum, copper, and more. BLCS's versatility enables it to serve diverse sectors including aerospace, automotive, electronics, construction, and even the creative arts. This extensive range of applications showcases the flexibility and adaptability of BLCS, reaffirming its position as a leading provider of innovative laser cutting solutions.Quality Assurance and Expertise:BLCS places a strong emphasis on quality assurance, ensuring that every project meets or exceeds customer expectations. The team of highly skilled technicians and engineers at BLCS possesses a wealth of experience and knowledge in laser cutting. From consulting on designs to using the most suitable techniques, BLCS offers expert guidance throughout the fabrication process. This collaborative approach ensures that clients receive superior results while optimizing cost-effectiveness.Commitment to Customer Satisfaction:At the core of BLCS's success lies its unwavering commitment to customer satisfaction. The company understands that every client has unique requirements, and it goes the extra mile to create tailored solutions. By providing rapid prototyping, efficient production processes, and exceptional customer service, BLCS ensures that clients' projects are completed accurately and on time.Contributing Towards Sustainability:BLCS also recognizes its responsibility towards environmental sustainability. The company actively adopts eco-friendly practices by minimizing waste materials and optimizing energy efficiency. By staying at the forefront of sustainable practices, BLCS not only meets industry expectations but also contributes to a greener future.Conclusion:Best Laser Cutting Service (BLCS) has established itself as a pioneering force in the laser-cutting industry. With its cutting-edge technology, diverse applications, unwavering dedication to excellence, and commitment to sustainability, BLCS continues to redefine precision fabrication. Through superior quality, customer-centric approach, and continuous innovation, BLCS ensures that businesses across industries can achieve their desired outcomes with unmatched precision and efficiency.

Top CNC Laser Cutters: A Comprehensive Guide to Choosing the Best Machine

Title: Advanced CNC Laser Cutter Revolutionizes Manufacturing IndustryIntroduction (100 words):In an era driven by technological advancements, cutting-edge machinery continues to reshape the manufacturing landscape. Addressing this demand, a renowned industry leader has launched their latest innovation, a state-of-the-art CNC Laser Cutter. This breakthrough product promises to revolutionize manufacturing processes with its exceptional precision, reliability, and efficiency. The highly-anticipated release comes from a company well-known for their commitment to quality craftsmanship and pushing the boundaries of technology. This news article will delve deeper into the noteworthy features and benefits of the cutting-edge CNC Laser Cutter while exploring the potential it holds for various industries.I. Unparalleled Precision and Efficiency (200 words):The CNC Laser Cutter offers unparalleled precision and efficiency, ensuring optimal performance and high-quality results. Equipped with advanced laser technology, this cutting-edge machine delivers precision cuts with remarkable accuracy, greatly reducing material waste. Its high-speed cutting capabilities enable rapid processing of a wide range of materials, including metals, plastics, and woods, making it suitable for a multitude of industries.The laser cutter's computer numerical control (CNC) system intelligently controls the cutting process, eliminating potential human error and increasing overall efficiency. With its intuitive user interface, operators can easily program and monitor the cutting parameters, allowing for seamless integration into various production workflows. Moreover, the machine's automated material feeding and removal systems further enhance productivity by reducing downtime.II. Versatile Applications (200 words):The CNC Laser Cutter boasts an impressive versatility in terms of applications. Its ability to accurately cut intricate designs and patterns makes it especially suitable for industries such as automotive, aerospace, electronics, and signage. The precision and consistency achieved by this machine enable manufacturers to meet the strictest industry standards and produce high-quality products with ease.Additionally, the CNC Laser Cutter empowers artisans and designers with the freedom to explore their creativity. It allows for intricate cuts and engravings on a myriad of materials, enabling the production of custom pieces, personalized gifts, and architectural elements. This versatility opens up numerous opportunities for entrepreneurs and small businesses to expand their product offerings and cater to niche markets.III. Enhanced Safety Features and Environmental Responsibility (200 words):The CNC Laser Cutter places considerable emphasis on safety features and environmental responsibility, ensuring a secure and sustainable manufacturing process. Equipped with advanced sensors, the machine automatically shuts down in case of any anomalies, thereby minimizing the risk of accidents and protecting operators.Furthermore, the laser cutter employs an efficient exhaust and filtration system to minimize harmful emissions, thus promoting a healthy working environment. It is also designed to consume less energy compared to traditional cutting methods, resulting in decreased carbon footprint and reduced manufacturing costs.Conclusion (100 words):In conclusion, the launch of the cutting-edge CNC Laser Cutter marks a significant milestone in the manufacturing industry. Its unparalleled precision, efficiency, and versatility offer manufacturers a competitive edge, enabling them to stay ahead in an increasingly demanding marketplace. The incorporation of advanced safety features and environmental responsibility further cements its position as a game-changing innovation. With its potential applications across various industries, this CNC Laser Cutter is bound to reshape production processes, streamline operations, and foster creativity. As technology continues to evolve, this state-of-the-art machinery is a testament to the ongoing pursuit of excellence in manufacturing.

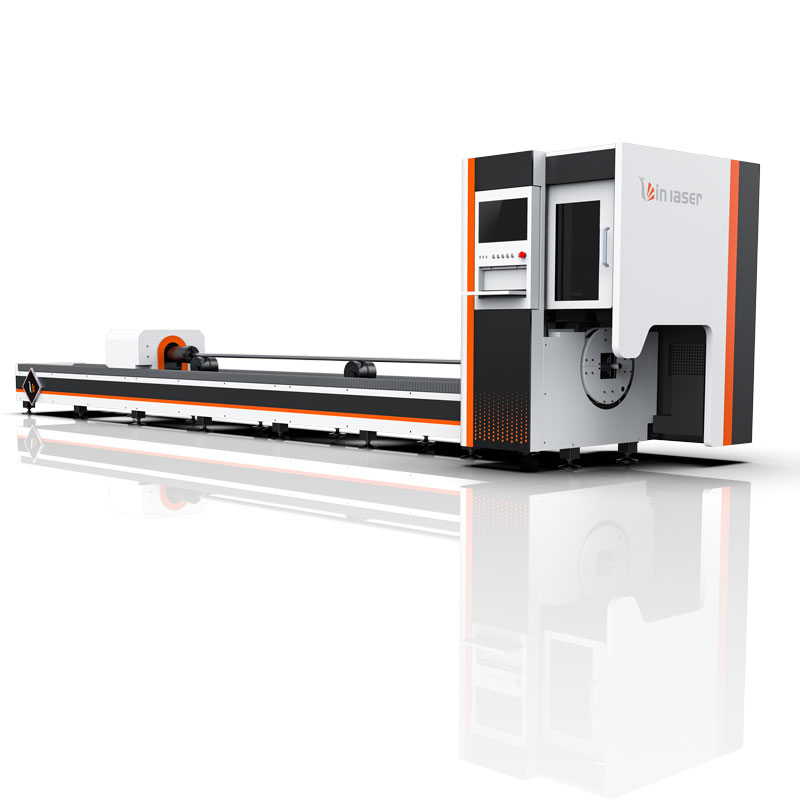

High-Quality Steel Tube Cutting Machine for Precision Cuts and Efficient Production

Steel Tube Cutting Machine Revolutionizes Industrial ManufacturingThe industrial manufacturing sector has recently been revolutionized by the introduction of the latest cutting-edge technology - the Steel Tube Cutting Machine. This innovative machine is set to transform the way steel tubes are cut, increasing efficiency, accuracy, and speed in the manufacturing process.The Steel Tube Cutting Machine, developed by a leading manufacturing company {}, is a state-of-the-art piece of equipment that is designed to meet the growing demands of the industry. It is capable of cutting steel tubes with precision and speed, making it a game-changer for companies involved in the production of steel-based products.With its advanced features and cutting-edge technology, the Steel Tube Cutting Machine is a significant advancement in the field of industrial manufacturing. The machine is capable of cutting steel tubes of various shapes and sizes, making it versatile and adaptable to different production needs. Its high precision cutting ensures that the end product meets the required specifications and standards, allowing manufacturers to produce high-quality steel components.The Steel Tube Cutting Machine is also equipped with automated features that streamline the cutting process, reducing the need for manual intervention and minimizing the risk of errors. This automation not only improves efficiency but also enhances workplace safety by reducing the exposure of workers to hazardous cutting processes.Furthermore, the machine's high-speed cutting capabilities allow for increased production output, contributing to overall productivity gains for manufacturers. This is particularly beneficial in industries where tight production deadlines and high-volume outputs are the norm.In addition to its technical capabilities, the Steel Tube Cutting Machine also comes with user-friendly software that is easy to operate and navigate. This intuitive interface makes it accessible to operators with varying levels of technical expertise, enabling them to maximize the machine's performance without extensive training.The introduction of the Steel Tube Cutting Machine by {} underscores the company's commitment to providing innovative solutions for the industrial manufacturing sector. With a track record of delivering cutting-edge equipment, {} has once again demonstrated its dedication to driving technological advancement and reshaping the industry landscape."We are thrilled to introduce the Steel Tube Cutting Machine to the market, as we believe it will bring about a significant transformation in the way steel tubes are processed," said a spokesperson for the company. "This machine represents the culmination of our extensive research and development efforts, and we are confident that it will deliver exceptional value to manufacturers looking to enhance their production capabilities."The launch of the Steel Tube Cutting Machine has garnered widespread attention and interest from manufacturers across various industries. Its potential to improve operational efficiency, reduce production costs, and elevate product quality has positioned it as a sought-after technology in the industrial manufacturing sector.As industry players look to stay competitive and meet the evolving demands of the market, the adoption of the Steel Tube Cutting Machine is expected to become a pivotal strategy for driving growth and innovation. Its impact on streamlining manufacturing processes and optimizing production workflows is set to define a new standard for steel tube cutting in the industry.In conclusion, the introduction of the Steel Tube Cutting Machine represents a significant milestone in the advancement of industrial manufacturing technology. Its innovative features, precision cutting capabilities, and potential to enhance productivity make it a game-changing solution for manufacturers seeking to stay ahead in a competitive market. As this cutting-edge technology continues to gain traction, it is poised to reshape the industry and set new benchmarks for efficiency and quality in steel tube processing.

New Technology Breakthrough in Pipe Manufacturing

Machine Pipe, a leading manufacturer in the field of industrial piping solutions, has been making waves in the industry with their innovative products and exemplary service. With a commitment to providing high-quality and reliable piping solutions, Machine Pipe has become a trusted name in the industry.The company has a strong focus on research and development, constantly seeking new materials and technologies to improve their products. This dedication to innovation has led to the development of a range of cutting-edge piping solutions that are known for their durability, efficiency, and cost-effectiveness. This has allowed Machine Pipe to establish a strong presence in the market, catering to a wide range of industries including oil and gas, chemical, water treatment, and more.One of the company's most notable products is their advanced pipe fitting system, which has been widely acclaimed for its superior performance and ease of installation. This system is designed to meet the diverse needs of industrial applications, offering a wide range of fittings and accessories that are compatible with various piping materials. This versatility allows customers to tailor their piping systems to their specific requirements, ensuring optimum performance and longevity.In addition to their innovative product range, Machine Pipe is also known for their exceptional customer service. The company takes pride in providing comprehensive support to their clients, offering expert advice, technical assistance, and after-sales service. This commitment to customer satisfaction has helped Machine Pipe build long-lasting relationships with their clients, earning them a reputation for reliability and trustworthiness.Machine Pipe's dedication to quality and excellence has not gone unnoticed, as the company has received numerous accolades and certifications for their products and services. Their commitment to environmental sustainability and safety standards has also been recognized, further solidifying their position as an industry leader.In a recent development, Machine Pipe has announced the launch of a new range of piping solutions that are set to revolutionize the industry. This new range features state-of-the-art materials and advanced technologies that are designed to meet the evolving needs of modern industrial applications. With a focus on performance, efficiency, and sustainability, these new products are expected to set a new standard in the industry.The company's spokesperson stated, "We are thrilled to introduce our latest range of piping solutions, which are the result of years of research and development. We believe that these products will offer unmatched performance and reliability, setting a new benchmark in the industry."The introduction of these new products is expected to further solidify Machine Pipe's position as a market leader, catering to the growing demand for high-quality and sustainable piping solutions. With their track record of excellence and commitment to innovation, Machine Pipe is well-positioned to continue serving as a trusted partner for industries around the world.As Machine Pipe continues to push the boundaries of innovation and excellence, the company remains committed to their core values of quality, reliability, and customer satisfaction. With their unparalleled expertise and dedication, Machine Pipe is set to maintain their position as a leader in the field of industrial piping solutions for years to come.

Laser Cutting of Hardox Steel News Highlights Its Potential

Title: Advanced Laser Cutting Techniques Revolutionizing Metal Fabrication IndustryIntroduction:Metal fabrication has been an integral part of various industries, from automotive to construction, for decades. As technological advancements continue to reshape the manufacturing landscape, companies are constantly seeking innovative solutions to enhance their production capabilities. Among these groundbreaking technologies, Hardox Laser Cutting has emerged as a game-changer, delivering unparalleled precision and efficiency in metal fabrication.In today's fast-paced world, where timelines and quality are crucial, Hardox Laser Cutting enables manufacturers to meet and surpass industry standards. By eliminating traditional cutting methods and embracing the power of laser technology, companies can now achieve exceptional accuracy, reduced lead times, and enhanced production efficiency – leading to improved overall performance.Benefits of Hardox Laser Cutting:1. Unmatched Precision:Hardox Laser Cutting utilizes high-powered lasers to accurately cut intricate designs and shapes in various grades of metal. The process eliminates the possibility of human error, ensuring precise and intricate cuts, resulting in perfectly fit components. This meticulous cutting accuracy eliminates the need for rework, reducing production costs for manufacturers.2. Enhanced Productivity:The introduction of Hardox Laser Cutting in metal fabrication processes has significantly increased productivity for companies. The speed at which the lasers can cut through metal surpasses traditional cutting methods, enabling faster production cycles. Manufacturers can now deliver products to market more rapidly, giving them a competitive edge in the industry.3. Versatility:Hardox Laser Cutting demonstrates remarkable versatility as it can be used on a wide range of metals, including stainless steel, aluminum, and various grades of carbon steel. With the ability to accommodate various thicknesses, this technology presents endless possibilities for manufacturers across different sectors. Whether it is cutting precise components for aeronautics or constructing intricate architectural designs, Hardox Laser Cutting is a reliable partner.4. Material Conservation:Traditional cutting methods often result in a significant loss of material due to imprecise cuts and inaccuracies. Hardox Laser Cutting tackles this issue head-on by minimizing wastage through its precise and precise cutting process. This material conservation not only reduces costs for manufacturers but also contributes to sustainable practices, aligning with global efforts toward environmental responsibility.5. Cost-Effective Solution:Hardox Laser Cutting offers a cost-effective solution for metal fabricators. With increased productivity, reduced labor costs, and minimized material waste, manufacturers can amplify their profitability. By optimizing production processes, businesses can allocate resources more effectively and enhance their return on investment.Conclusion:Hardox Laser Cutting has emerged as a transformative technology, revolutionizing the metal fabrication industry. As manufacturers strive to meet the demands of an ever-evolving market, this advanced cutting technique proves to be indispensable. With its unmatched precision, improved productivity, versatility, material conservation, and cost-effective benefits, companies can now elevate their metal fabrication processes to new heights. With Hardox Laser Cutting as a reliable ally, we can expect businesses to thrive in the competitive landscape with superior quality products and timely deliveries.

Top Electric Cutting Machine: Discover the Latest Technology

Cutting Machine Electric Introduces Advanced Technology for Precision CuttingCutting Machine Electric, a leading global manufacturer of cutting machines, has introduced a new line of cutting machines that incorporate advanced technology for precision cutting. The company, which has been in the cutting machine industry for over 30 years, is dedicated to providing innovative solutions for a wide range of cutting needs.The new line of cutting machines features state-of-the-art technology that allows for more accurate and efficient cutting. With a focus on precision, the machines are equipped with high-tech sensors and cutting blades that deliver superior results. This advancement in technology ensures that the cutting process is completed with maximum precision and minimal waste, leading to cost savings for the users.The cutting machines are designed to be versatile and can be used for a variety of materials, including metal, plastic, and wood. This broad range of capabilities makes the machines suitable for a wide range of industries, including manufacturing, construction, and automotive.In addition to the advanced technology, Cutting Machine Electric is committed to ensuring that their products are user-friendly and easy to operate. The machines are equipped with intuitive controls and a user-friendly interface, making them accessible to operators with varying levels of experience.Furthermore, the company is dedicated to providing excellent customer support and service. They offer comprehensive training and support to ensure that their customers are able to fully utilize the capabilities of their cutting machines. This commitment to customer satisfaction has earned Cutting Machine Electric a reputation for reliability and excellence in the industry.The new line of cutting machines is the result of extensive research and development by Cutting Machine Electric's team of engineers and designers. The company invests heavily in research and development to stay at the forefront of technological advancements in the cutting machine industry. This commitment to innovation has allowed Cutting Machine Electric to consistently deliver cutting-edge solutions to their customers."We are proud to introduce our new line of cutting machines, which incorporate the latest technology for precision cutting," said a spokesperson for Cutting Machine Electric. "Our goal is to provide our customers with cutting machines that are not only technologically advanced but also easy to use and reliable. We believe that our new line of cutting machines will set a new standard for precision cutting in the industry."With the introduction of their new line of cutting machines, Cutting Machine Electric continues to solidify their position as a leading provider of cutting solutions. Their commitment to innovation, customer satisfaction, and reliability sets them apart in the industry, and their new line of cutting machines further cements their reputation as a trusted and innovative manufacturer.The new line of cutting machines from Cutting Machine Electric is now available for purchase, and the company is excited to see the positive impact that this advanced technology will have on the cutting industry. Customers who are interested in learning more about the new line of cutting machines can visit Cutting Machine Electric's website or contact their sales team for more information.As Cutting Machine Electric continues to push the boundaries of innovation in the cutting machine industry, they are poised to remain a key player in the market for years to come. Their dedication to excellence and customer satisfaction ensures that their products will continue to be sought after by businesses and industries looking for top-of-the-line cutting solutions.

High-Performance Co2 Laser Cnc for Precision Cutting - Latest Updates

Laser CNC Co2 technology has revolutionized the manufacturing industry, providing businesses with an efficient and precise method of cutting and engraving a wide range of materials. This groundbreaking technology has allowed companies to streamline their production processes and create high-quality products with intricate designs and patterns. One company that has been at the forefront of this innovation is {}. With their state-of-the-art laser CNC Co2 machines, they have been able to offer cutting-edge solutions to businesses across various industries.{} is a leading provider of laser CNC Co2 technology, offering a wide range of cutting and engraving machines designed to meet the needs of businesses of all sizes. Their machines are equipped with advanced features that ensure optimal precision and efficiency, allowing their customers to achieve excellent results with every project. The company takes pride in their commitment to innovation and continuous improvement, constantly pushing the boundaries of what is possible with laser CNC Co2 technology.One of the key advantages of {}'s laser CNC Co2 machines is their versatility. These machines are capable of cutting and engraving a variety of materials, including wood, acrylic, plastic, glass, and even metal. This flexibility has made it possible for businesses to explore new possibilities in product design and development, opening up a world of creative opportunities. Whether it's creating intricate patterns on wooden panels or engraving precise markings on metal components, {}'s machines have proven to be invaluable tools for businesses looking to take their manufacturing capabilities to the next level.In addition to their cutting and engraving capabilities, {}'s laser CNC Co2 machines are also known for their speed and efficiency. These machines are capable of completing projects in a fraction of the time it would take traditional methods, allowing businesses to meet tight deadlines and fulfill customer orders with ease. This has not only improved productivity for their customers but has also allowed them to take on more projects and expand their businesses.Another standout feature of {}'s laser CNC Co2 machines is their user-friendly design. The company understands that not all businesses have extensive experience with this technology, which is why they have ensured that their machines are easy to operate and maintain. With intuitive controls and comprehensive training and support, businesses can quickly master the art of laser CNC Co2 cutting and engraving, giving them the confidence to take on even the most ambitious projects.As a testament to the quality and effectiveness of their machines, {} has received glowing feedback from their customers. Businesses have praised the precision and reliability of {}'s laser CNC Co2 machines, noting that they have been able to achieve results that were previously unattainable with other cutting and engraving methods. Many have also highlighted the exceptional level of support and service provided by the company, citing their dedication to helping businesses succeed.Looking ahead, {} is committed to continuing their mission of driving innovation in the laser CNC Co2 industry. They are constantly researching and developing new technologies and features to further enhance the capabilities of their machines, enabling businesses to stay ahead of the curve and remain competitive in their respective markets. With a focus on quality, performance, and customer satisfaction, {} is poised to remain a leader in the laser CNC Co2 industry for years to come.In conclusion, the advancements in laser CNC Co2 technology have brought about a new era of manufacturing, and {} is at the forefront of this revolution. With their cutting-edge machines and unwavering commitment to excellence, they have empowered businesses to elevate their production capabilities and achieve remarkable results. As the demand for precision and efficiency continues to grow, {}'s laser CNC Co2 machines are set to play a crucial role in shaping the future of manufacturing.

Ultimate Guide to Laser Cutting Machines for Precision Plate Cutting

Title: Advanced Plate Laser Cutting Machine Revolutionizes Metal Fabrication IndustryIntroduction:In today's rapidly evolving technology landscape, innovative solutions are continuously emerging to enhance various industries' efficiency and productivity. In line with this trend, the introduction of an advanced Plate Laser Cutting Machine has taken the metal fabrication industry by storm. This cutting-edge technology is set to revolutionize the way metal components are manufactured, ultimately redefining the sector's capabilities and setting new standards of precision and quality.Product Overview and Features:The Plate Laser Cutting Machine is a state-of-the-art equipment designed to provide reliable and efficient cutting solutions for a wide range of metal plates. With its precision laser cutting technology, this machine can seamlessly cut through various metals, including steel, aluminum, copper, and stainless steel, among others. The machine is equipped with a powerful laser source, efficient cooling systems, and intelligent automation features, making it an indispensable asset for metal fabrication companies seeking enhanced output.Key Features of the Plate Laser Cutting Machine include:1. High Precision Cutting: The laser cutting technology employed by this machine ensures exceptional precision, allowing intricate designs and complex shapes to be accurately reproduced in a variety of metal plates.2. Versatile Applications: The machine's flexibility enables it to be used in numerous industries, such as automotive, aerospace, construction, and electronics. It can effortlessly handle demanding cutting tasks, whether it is creating intricate components or executing mass production requirements.3. Efficiency and Speed: The Plate Laser Cutting Machine significantly reduces production time and effort due to its fast cutting speed and automated features. This ensures optimal productivity for metal fabricators and enables them to meet tight project deadlines with ease.4. Enhanced Safety: Incorporated safety mechanisms prioritize the protection of operators and workers using the machine. The machine features automated safety guards, real-time monitoring, and emergency stop functions, ensuring a secure working environment.Benefits to the Metal Fabrication Industry:The introduction of the Plate Laser Cutting Machine marks a significant milestone in the metal fabrication industry. Its cutting-edge features offer several advantages, including:1. Improved Product Quality: The machine's high precision and accuracy guarantees flawless cuts, reducing the need for extensive post-processing and improving overall product quality.2. Streamlined Workflow: The automated features of the machine streamline the manufacturing process by reducing human intervention. This boosts efficiency and allows fabricators to allocate their resources more effectively.3. Cost Savings: The cutting-edge machine optimizes material usage, reducing waste and minimizing production costs. Additionally, its high-speed performance enhances productivity, effectively lowering labor expenses.4. Design Freedom: The Plate Laser Cutting Machine enables the production of complex designs and shapes with ease, empowering manufacturers with greater design freedom and flexibility, ultimately leading to more innovative and unique products.Company Overview:The manufacturer of the Plate Laser Cutting Machine is a highly reputable technology company committed to developing cutting-edge industrial solutions. With extensive experience and expertise, the company has consistently delivered innovative products that redefine the capabilities of various industries.Conclusion:The advanced Plate Laser Cutting Machine has heralded a significant breakthrough in metal fabrication, revolutionizing the industry by setting new benchmarks in precision cutting, speed, and overall quality. With its versatile applications and exceptional features, this cutting-edge technology is poised to reshape the metal fabrication landscape, empowering manufacturers to unlock increased productivity, efficiency, and design freedom.

Video highlights top features of CNC fiber laser cutting machines for metal materials

, CNC Fiber Laser, High Precision Cutting, Metal Cutting.In today's world, the demand for precision cutting has increased manifold. Be it in the manufacturing industry or the automobile sector, precision cutting is required in all areas of modern production. And with the advancement in technology, we have seen a significant change in the machines that are used for cutting metals.One of the most widely used machines for high precision cutting is the CNC fiber laser cutting machine. A CNC fiber laser cutting machine is a technological marvel that uses an advanced fiber laser generator and ball screw moving system to cut different kinds of metal with high precision and speed.CNC fiber laser cutting machines offer a competitive edge to businesses by increasing their productivity and efficiency. They are also easy to operate, and their maintenance or adjustment does not require much time or effort. In this blog post, we will delve into the features and benefits of CNC fiber laser cutting machines.High Precision Cutting with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their precision cutting capabilities. They use advanced fiber laser generator technology to produce a high-intensity laser beam, which is then used to cut the metal with great precision. CNC fiber laser cutting machines can cut through different thicknesses of metals, including stainless steel, carbon steel, and aluminum, with great accuracy.The precision cutting feature of CNC fiber laser cutting machines makes them a perfect tool for creating intricate shapes and patterns in metals. They are ideal for making complex cuts needed in industries like aerospace, manufacturing, and automotive.Increased Efficiency with CNC Fiber Laser Cutting MachinesCNC fiber laser cutting machines are known for their high-speed operation. They can perform cuts at a much faster pace than other cutting machines in the market. The ball screw moving system used in CNC fiber laser cutting machines ensures that the machine moves smoothly and quickly, resulting in faster processing times.The high-speed operation of CNC fiber laser cutting machines makes them an ideal choice for businesses that need to cut a large number of metal pieces in a short amount of time. This efficiency helps businesses reduce their production times and increase their output.Low Maintenance and Easy to OperateAnother significant advantage of CNC fiber laser cutting machines is their low maintenance requirements. Since the laser is transmitted by fiber, there is no need for frequent maintenance or adjustments to the laser optical path. This reduces operational costs while ensuring consistent, high-quality results.CNC fiber laser cutting machines are also easy to operate. They come with user-friendly software that allows operators to design and execute precise cuts without any hassle. The software allows for customization of shapes and patterns, enabling greater design flexibility for businesses.ConclusionCNC fiber laser cutting machines are changing the way businesses cut metals today. Their high precision, speed, and efficiency have made them a preferred choice for industries that require precise cutting and fast processing times. Their low maintenance and ease of use have made them a cost-effective tool for businesses of all sizes.If you are looking for a machine that can cut metal with precision and speed while reducing your operational costs, CNC fiber laser cutting machines are the answer. Invest in a CNC fiber laser cutting machine today and experience the benefits firsthand!

Revolutionary Fiber Laser: Next-Gen Technology Redefining Industries

Fiber Laser: Revolutionizing the Industrial SectorIn today's industrial world, precision and accuracy are the new keys to success. Companies are looking for ways to improve their productivity and enhance their product quality. With the increasing demand for sophisticated and complex industrial processes, manufacturers require advanced tools that deliver reliable and efficient results. This is where Fiber Laser technology comes into play.Fiber Laser, a leading innovator in the laser technology industry, has developed game-changing solutions for a variety of applications. The company's state-of-the-art Fiber Laser systems are designed to provide high-quality and precise results, ensuring that users to stay ahead of the curve in the competitive industrial sector.The company's Fiber Laser technology is based on the principle of stimulated emission, which produces a high-intensity beam of light. This beam passes through a fiber-optic cable, which amplifies and directs the emission towards the targeted material. The laser energy interacts with the material, causing it to heat up and eventually melt or evaporate. This process is highly accurate and reliable compared to traditional cutting and engraving methods.Fiber Laser's range of products includes laser cutting, laser welding, laser marking, and laser engraving systems, which cater to various industrial requirements. Their Laser cutting systems are capable of cutting through a wide range of materials, including metals, plastics, and ceramics. Moreover, the cutting process is so precise that it can produce intricate designs and shapes with ease.The Laser welding systems provided by Fiber Laser are highly efficient and can withstand the stresses of heavy-duty welding applications. Furthermore, these systems come equipped with advanced features such as precision controls and real-time monitoring systems, which allow users to streamline their workflow and reduce downtime.Laser marking and Laser engraving systems available from the company are equally advanced and are designed to meet the diverse needs of the industrial sector. These systems can mark and engrave materials with high precision and accuracy and offer an excellent alternative to traditional methods such as printing and stamping.Fiber Laser's innovative products are not only revolutionizing the industrial sector but also making a significant impact on the environment. The Fiber Laser technology is eco-friendly, producing no harmful emissions or waste and thus, contributing towards a cleaner and greener future.The company's Fiber Laser technology has been implemented in various industries worldwide, including automotive, aerospace, electronics, and medical. Their continued focus on innovation and quality has earned them a reputation as a trusted provider of laser technology solutions. The company's philosophy of providing excellent customer support ensures that users have access to a team of skilled professionals who can assist with any technical or service-related queries.ConclusionFiber Laser is at the forefront of the Laser technology industry, delivering cutting-edge solutions that empower manufacturers to achieve their goals. Their Fiber Laser systems are highly efficient, precise, and reliable, making them an asset in today's competitive industrial sector. The innovative technology and their commitment to quality, backed by an excellent customer support system, have earned them a reputation as a trusted provider of laser technology worldwide. As Fiber Laser's reach and influence continue to grow globally, there is no doubt that they will continue to shape the future of the industrial sector, enabling companies worldwide to stay ahead of the competition.