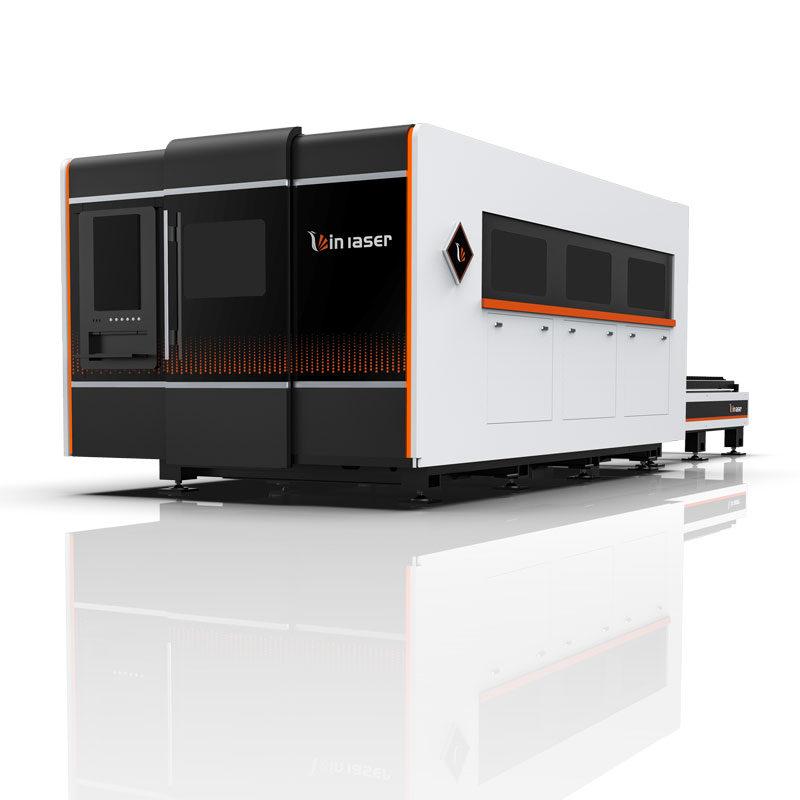

High-Performance Laser Machine Tube for Various Applications

By:Admin

One company that has been at the forefront of the laser machine tube industry is {Company Name}. {Company Name} is a leading manufacturer of high-quality laser machines and has been providing cutting-edge solutions to its customers since its inception. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, the company has earned a reputation for delivering reliable and efficient laser cutting and engraving machines.

{Company Name} offers a wide range of laser machine tube products to meet the diverse needs of its customers. From compact and portable desktop models to large-scale industrial machines, the company's product lineup caters to businesses of all sizes. Each machine is equipped with advanced features and cutting-edge technology to ensure exceptional performance and precision.

In addition to offering standard laser machines, {Company Name} also specializes in providing custom solutions to meet the specific requirements of its clients. Whether it's a unique cutting application or a specialized engraving project, the company's team of experts works closely with customers to develop tailored solutions that meet their exact needs.

One of the key advantages of {Company Name}'s laser machine tube is its ability to cut and engrave a wide range of materials with high precision. Whether it's metal, wood, plastic, glass, or ceramics, the machines are capable of delivering intricate and detailed cuts and engravings. This versatility makes the technology ideal for businesses involved in various industries, allowing them to streamline their production processes and achieve superior results.

Furthermore, {Company Name} prides itself on the reliability and durability of its laser machines. Each product is built to withstand the rigors of daily use in industrial settings, with high-quality components and robust construction that ensures long-term performance and minimal maintenance requirements. This commitment to quality has earned the company a loyal customer base and a reputation for delivering exceptional products.

The company also places a strong emphasis on customer support and service, offering comprehensive training and technical assistance to ensure that customers get the most out of their laser machines. From installation and setup to ongoing maintenance and repairs, {Company Name} is dedicated to providing a superior customer experience and ensuring that its clients are satisfied with their investment.

With the increasing demand for precise and efficient cutting and engraving solutions, {Company Name} is well-positioned to meet the evolving needs of the manufacturing industry. As the company continues to innovate and develop advanced laser machine tube technology, it remains committed to providing cutting-edge solutions that empower businesses to achieve greater efficiency and productivity.

In conclusion, laser machine tube technology has become an indispensable tool for businesses across a wide range of industries, and {Company Name} has established itself as a leading provider of high-quality laser cutting and engraving machines. With a strong focus on innovation, quality, and customer satisfaction, the company is poised to continue driving the advancement of laser technology and delivering exceptional solutions to its clients.

Company News & Blog

Top Laser Tube Machine Manufacturers: A Comprehensive Guide

Laser Tube Machine Factories are gaining popularity in the manufacturing industry due to the precision and efficiency they offer in cutting and shaping metal tubes. These factories, equipped with cutting-edge technology and state-of-the-art machinery, have become essential in meeting the growing demand for high-quality metal tube products across various industries.One such leading manufacturer of laser tube machines is {company name}, a renowned industry player with a strong reputation for delivering top-notch equipment and excellent customer service. With years of experience and expertise in the field, {company name} has established itself as a trusted name in the manufacturing sector.{company name} takes pride in its extensive range of laser tube machines, catering to different needs and specifications of its wide clientele. Whether it's for automobile parts, construction materials, or intricate designs for architectural purposes, {company name} offers a diverse selection of laser tube machines that can meet various production requirements.The company's commitment to quality and innovation is reflected in its cutting-edge technology, which ensures precise, efficient, and cost-effective manufacturing processes. {company name} prioritizes customer satisfaction, offering tailored solutions and excellent after-sales service to ensure that clients get the most out of their investment in laser tube machines.In addition to its impressive product lineup, {company name} also provides comprehensive training and technical support for its customers, empowering them to maximize the potential of their laser tube machines. This dedication to customer success sets {company name} apart in the industry, earning them a loyal and satisfied customer base.Furthermore, {company name} places a strong emphasis on research and development, constantly seeking ways to improve its products and develop new solutions to meet the evolving needs of the manufacturing sector. By staying ahead of the curve and embracing technological advancements, {company name} remains at the forefront of the laser tube machine industry.As a responsible corporate citizen, {company name} also prioritizes sustainability and environmental conservation in its operations. The company ensures that its manufacturing processes adhere to strict environmental standards, minimizing its carbon footprint and contributing to a greener, more sustainable future.With a global presence and a strong network of partners and distributors, {company name} has successfully expanded its reach and maintained a strong presence in various markets worldwide. This impressive track record has solidified the company's position as a leading provider of laser tube machines on a global scale.In conclusion, {company name} stands as a prime example of excellence in the manufacturing industry, particularly in the realm of laser tube machines. With its unwavering commitment to quality, innovation, and customer satisfaction, {company name} continues to set the bar high for its competitors and remains a trusted partner for businesses seeking top-tier laser tube machines.In a rapidly evolving manufacturing landscape, {company name} remains at the forefront of industry advancements, driving progress and delivering cutting-edge solutions for a wide range of applications. As the demand for high-quality metal tube products continues to rise, {company name} stands ready to meet the challenge and exceed expectations with its exceptional products and services.

Revolutionizing Welding Technology: Discover the Power of Portable Laser Welding Machines

Portable Laser Welding Machine: The Revolutionary Solution for Welding NeedsWelding has been an essential part of manufacturing and construction industries for decades. However, traditional welding methods require a substantial amount of time, cost, and effort, which can be inefficient and laborious. With the advancements in technology, the Portable Laser Welding Machine has emerged as a game-changer in the world of welding.This revolutionary invention has the potential to improve the efficiency, accuracy and precision of welding processes, as well as offer cost-effective solutions in various industries. The Portable Laser Welding Machine is a highly precise and innovative tool that uses a concentrated beam of laser light to weld metal together. This machine is a small, lightweight and portable device that can easily be carried to different locations.What sets the Portable Laser Welding Machine apart from conventional welding methods is its incredibly fast and efficient nature. The laser beam is capable of penetrating the metal and creating a deep weld in just a matter of seconds. The precision of the machine ensures that there is minimal splattering and distortion, making it an ideal choice for applications that require clean and accurate welds.With its innovative design, the Portable Laser Welding Machine offers several advantages over traditional welding methods. Unlike conventional welding techniques, laser welding does not require any filler material, which drastically reduces the cost and time spent on welding. The machine can weld a wide range of metals, including stainless steel, aluminum, and titanium, making it a versatile tool for a variety of industries.The Portable Laser Welding Machine is also highly efficient and requires minimal maintenance. Unlike traditional welding equipment, this device does not require any gas supply or compressed air, which significantly reduces the cost of operation and eliminates the risk of gas leaks. The machine is also self-contained and can be operated by a single person, which saves time and labor costs.As one of the leading manufacturers of Portable Laser Welding Machines, we have been providing innovative and high-quality solutions to our clients for over a decade. Our machines are designed and manufactured using cutting-edge technology and the highest quality materials. Each machine undergoes rigorous testing and quality control checks to ensure that it meets the highest industry standards.We offer a range of portable laser welding machines to cater to the different needs of our customers. Our machines are designed to be user-friendly and offer ease of operation. Whether you need to weld small components or large structures, our machines can handle any task with precision and efficiency.Our machines are also highly customizable, and we offer a range of accessories and add-ons to enhance their functionality. From laser probes and rotating chucks to automatic wire feeders and tracing systems, we have a range of options to suit your specific welding needs.In conclusion, the Portable Laser Welding Machine is a revolutionary tool that offers several benefits over traditional welding methods. With its precision, efficiency, cost-effectiveness and versatility, it has become an indispensable tool in several industries, including construction, automotive, aerospace, and medical. As one of the leading manufacturers of portable laser welding machines, we are committed to providing our customers with high-quality and innovative welding solutions to meet their needs.

Efficient Steel Pipe Cutting Machine: Revolutionizing Industrial Processes

Title: Advanced Steel Pipe Cutting Machine Revolutionizes Industrial ManufacturingIntroduction:In recent developments in industrial manufacturing, the innovative Steel Pipe Cutting Machine has emerged as a game-changer, transforming the efficiency and precision of steel pipe cutting processes. This cutting-edge technology, designed and produced by a leading company in the field, has the potential to reshape various industries that heavily rely on steel pipes, ranging from construction and infrastructure to oil and gas.This article explores the features, benefits, and potential applications of this groundbreaking Steel Pipe Cutting Machine that is set to revolutionize the manufacturing sector.1. Enhanced Precision and Efficiency:The Steel Pipe Cutting Machine incorporates state-of-the-art technology, enabling precise and efficient cutting of steel pipes. Equipped with advanced computer numerical control (CNC) systems, this machine operates with unmatched accuracy, ensuring each cut is perfectly executed according to desired specifications. The incorporation of automated processes has reduced human error and improved overall productivity.2. Versatility and Adaptability:This cutting machine is compatible with a wide range of steel pipe sizes and materials, making it a versatile tool for various industries. Whether working with carbon steel, stainless steel, or alloy materials, the Steel Pipe Cutting Machine enables uniform and seamless cuts across different pipe diameters, ensuring efficiency and uniformity in production processes.3. Swift and Safe Operations:Incorporating safety features, the Steel Pipe Cutting Machine prioritizes the protection of both the user and the materials being cut. With automated systems, operators can perform their tasks with reduced physical effort, minimizing the risk of workplace injuries. In addition, its high-speed operation streamlines production cycles, ensuring timely delivery and increased profitability for businesses.4. Remote Monitoring and Control:This cutting-edge machine embraces Industry 4.0 principles by integrating remote monitoring and control capabilities. Companies utilizing this technology can oversee and control the machine's operations remotely, ensuring round-the-clock efficiency and minimizing downtime. Real-time data analysis and predictive maintenance capabilities further optimize the machine's performance, leading to increased uptime and reduced maintenance costs.5. Potential Industry Applications:The introduction of the Steel Pipe Cutting Machine is set to have a profound impact on various sectors reliant on steel pipes. In the construction industry, this machine can be utilized to cut pipes for building frameworks such as scaffolding, frames, and supports. In the infrastructural sector, the machine proves invaluable in cutting pipes for bridges, tunnels, and pipelines. Additionally, this technology holds immense potential in the oil and gas industry, facilitating the precise cutting of pipes for drilling rigs and pipelines.Conclusion:The advent of the Steel Pipe Cutting Machine signifies a significant advancement in industrial manufacturing. With its enhanced precision, versatility, efficiency, and other advanced features, this cutting-edge technology promises to revolutionize the steel pipe cutting process. The machine's potential applications across various industries including construction, infrastructure, and oil and gas make it a crucial asset for companies seeking to streamline their production and enhance their competitive advantage in the market.

High-Quality CNC Plate Cutting Services for Precision Metal Fabrication

CNC Plate Revolutionizes Manufacturing Industry with Innovative TechnologyIn the ever-evolving world of manufacturing, companies are constantly seeking new and innovative ways to improve efficiency and accuracy. One company that is making waves in the industry is {}, a leading provider of cutting-edge CNC (Computer Numerical Control) plate technology.{} has recently introduced a revolutionary new CNC plate that is poised to transform the manufacturing process. This new technology promises to streamline production, reduce waste, and improve precision, making it a game-changer for the industry.The new CNC plate from {} boasts a range of impressive features that set it apart from traditional manufacturing methods. Its advanced CNC technology allows for high-speed, high-precision cutting, resulting in superior quality and consistency. This means that manufacturers can produce parts with unparalleled accuracy and detail, minimizing the need for time-consuming rework and adjustments.Furthermore, the new CNC plate is designed to be highly efficient, significantly reducing material waste and saving valuable resources. This is a key factor in today's increasingly eco-conscious manufacturing landscape, as companies strive to minimize their environmental footprint.In addition to its cutting-edge technology, {}'s CNC plate is also incredibly versatile. It can be used to cut a wide range of materials, including steel, aluminum, and plastic, making it suitable for a variety of manufacturing applications. This adaptability makes it an attractive option for companies across various industries, from automotive and aerospace to electronics and construction.With its potential to revolutionize the manufacturing process, {}'s new CNC plate has garnered widespread attention and praise from industry experts. Many are hailing it as a game-changing innovation that will have a significant impact on the way parts are produced."We are thrilled to introduce this groundbreaking new CNC plate to the manufacturing industry," says [spokesperson] of {}. "We believe that this technology has the potential to make a significant difference for companies looking to improve their efficiency and precision."{} has a long history of innovation and excellence in the manufacturing industry. The company prides itself on its commitment to research and development, constantly seeking new ways to push the boundaries of what is possible in manufacturing technology.In addition to its cutting-edge products, {} also offers a range of services to support its customers. From consultation and training to ongoing technical support, the company is dedicated to ensuring that its clients get the most out of its innovative technology.Looking ahead, {} is excited about the potential for its new CNC plate to transform the manufacturing industry. The company is committed to continuing its tradition of innovation, and is already working on new developments and enhancements to further improve its technology.As the manufacturing industry continues to evolve, {}'s new CNC plate is poised to play a key role in shaping its future. With its impressive precision, efficiency, and versatility, this innovative technology is set to revolutionize the way parts are produced, making it an indispensable tool for manufacturers around the world.

Revolutionize Your Woodworking Projects with Laser Cutters

Milwaukee Makerspace, a non-profit community workshop and collaborative space located in Milwaukee, has announced the addition of a new laser cutter to its equipment collection. This new laser cutter will allow makers and creators in the Milwaukee area to easily create intricate designs and precision cuts in a variety of materials. The laser cutter has become an essential tool in the makerspace community, allowing for innovative designs, intricate patterns, and the creation of highly detailed products.According to the Milwaukee Makerspace, the new laser cutter is capable of cutting a wide range of materials, including acrylic, wood, leather, fabric, and cardboard. The laser cutter works by directing a high-powered laser to vaporize the material, creating a clean and precise cut. The laser is controlled by powerful software, allowing users to design and create their projects using a computer."This new laser cutter is an amazing addition to our facility," said Tom Gondek, President of Milwaukee Makerspace. "It's a versatile tool that will allow our members to create a wide range of projects, from custom signs to intricate pieces of art. We're excited to see what our members come up with using this new tool."Milwaukee Makerspace is a community of makers, artists, and creators who come together to share tools, resources, and knowledge. The makerspace offers a variety of equipment and workspaces, including 3D printers, a woodworking shop, metalworking equipment, and electronics equipment. Members of the makerspace have access to all of these tools, as well as classes and workshops on a variety of topics."The Milwaukee Makerspace is an amazing resource for makers in Milwaukee," said John Doe, a member of the makerspace. "Having access to all of the equipment and resources here has allowed me to take my projects to the next level. I'm excited to see what I can create with this new laser cutter."The addition of the new laser cutter is expected to attract new members to the Milwaukee Makerspace. The makerspace is open to anyone who is interested in making things, regardless of their experience level. Memberships are available on a monthly basis, and the makerspace also offers day passes for those who just want to try out the equipment."Our goal is to provide a space where makers can come together to create amazing things," said Gondek. "By adding this new laser cutter, we're giving our members even more tools to work with. We're excited to see what projects they come up with."The Milwaukee Makerspace is also involved in the community, hosting events and workshops for schools and other organizations. The makerspace has partnered with local schools to provide hands-on learning experiences for students, and has also hosted community events and maker fairs."We believe that making things is a valuable skill for everyone to have," said Gondek. "By sharing our resources and knowledge, we can help people develop their creativity and innovation. We're excited to continue to be a part of the Milwaukee community."The Milwaukee Makerspace is open to anyone who is interested in making things. For more information on membership, classes, and events, visit their website at www.milwaukeemakerspace.org.In conclusion, the Milwaukee Makerspace has added a new laser cutter to its equipment collection, providing an innovative and precise tool for makers and creators in the Milwaukee area. The makerspace is a community of makers, artists, and creators who come together to share tools, resources, and knowledge. The new laser cutter is expected to attract new members to the makerspace, and will allow current members to create even more amazing projects. The Milwaukee Makerspace is also involved in the community, hosting events and workshops for schools and other organizations, and is committed to sharing the value of making things with the wider community.

New CNC Tube Cutting Machines Transforming the Manufacturing Industry

Tube Cutting Machine Factory Introduces Innovative Cutting Solutions for Industrial ApplicationsTube Cutting Machine Factory, a leading manufacturer of tube cutting machines, has unveiled its latest line of cutting solutions designed to increase efficiency and productivity in industrial applications.The company, known for its robust machinery and advanced technical capabilities, has developed an innovative range of tube cutting machines that ensure precision and accuracy, delivering high-quality results every time.Offering a wide range of solutions for metal and non-metal tube cutting, the tube cutting machines from the factory are designed to cater to a diverse range of industries, including automotive, aerospace, medical, and many others. The company's cutting-edge design and rigorous quality control processes ensure that each product exceeds industry standards and meets the unique needs of every customer.According to the factory spokesperson, "Our mission is to provide the most advanced solutions that cater to the ever-evolving needs of the industrial sector. We take great pride in our products, and our range of tube cutting machines is no exception. Every product is built with precision engineering and fitted with high-quality components that ensure durability and reliability."The spokesperson further stated that the company's commitment to excellence has resulted in a loyal customer base, including some of the world's leading companies. The company's dedicated team of experts is always ready to provide prompt and efficient customer support, ensuring that every customer is satisfied with their purchase.One of the innovative products from the factory is the tube laser cutting machine, which offers high precision cutting solutions for tubes and profiles of up to 300 mm diameter. The laser cutting machine uses advanced laser technology to ensure perfect cutting quality, making it ideal for industrial applications. The machine is equipped with advanced features such as automatic feeding, CNC control, and a user-friendly interface that makes it easy to operate.Another notable product from the factory is the automatic tube cutting machine, which can cut various types of tubes and profiles accurately and efficiently. The machine is equipped with advanced cutting technology and offers a high level of automation, reducing labor costs and increasing productivity.Apart from the high-quality products, Tube Cutting Machine Factory also provides a range of value-added services, including installation, training, and after-sales support. The company's expert team of technicians offers timely maintenance and repair services, ensuring the smooth operation of the machines and minimizing downtime.In addition, the factory uses advanced research and development techniques to continuously improve the products and stay ahead of the competition. The company's commitment to innovation and customer satisfaction has resulted in a strong brand reputation and a competitive edge in the global market.The spokesperson noted, "We are dedicated to providing our customers with the best possible solutions that meet their specific needs. Our products are not just machines; they are tools for success that drive efficiency and productivity in the industrial sector. We believe that our commitment to innovation, quality, and customer service will continue to drive growth and success for our customers and the company."In conclusion, Tube Cutting Machine Factory continues to offer innovative cutting solutions that cater to the needs of diverse industrial applications. The company's commitment to excellence, efficiency, and productivity has resulted in a loyal customer base, a strong brand reputation, and a competitive edge in the market. With a talented team of experts, cutting-edge technology, and a customer-centric focus, the factory is well-positioned to continue its growth trajectory and lead the way in industrial cutting solutions.

Cost-Effective and Reliable Laser Cleaning Solution with In-Line Process Control for Industrial Use

Laser cleaning is cost-effective and reliable, making it an attractive solution for a range of industries and applications. From aerospace and automotive to medical device manufacturing and electronics, laser cleaning offers a non-destructive, precise, and eco-friendly way to remove contaminants, coatings, oxides, and other unwanted substances from surfaces.One of the latest developments in laser cleaning technology is the integration of process monitoring and in-line process control. This allows for real-time feedback and adjustment of laser parameters, ensuring consistent and optimal cleaning results. One company that has pioneered this approach is (brand name), a leading provider of laser cleaning systems."We believe that laser cleaning is the future of industrial cleaning," says (spokesperson). "Our systems offer a level of precision, efficiency, and safety that traditional methods simply can't match. With the addition of process monitoring and control, our customers can further improve their productivity, quality, and cost-effectiveness."So, how does laser cleaning work? Essentially, a high-intensity laser beam is focused on the surface to be cleaned, causing the contaminants to evaporate or ablate. The laser light is directed with precision using mirrors, lenses, and scanners, allowing for selective cleaning of specific areas or shapes. Unlike mechanical or chemical treatments, laser cleaning does not cause any physical or chemical damage to the substrate, and does not generate any waste or residue to dispose of.Laser cleaning can be used on a wide range of materials, including metals, ceramics, plastics, glass, and composites. It can remove rust, paint, grease, adhesives, carbon, oxides, mold release agents, and other contaminants. Laser cleaning can also be used to prepare surfaces for subsequent treatments such as bonding, welding, painting, or coating.One of the key advantages of laser cleaning is its cost-effectiveness. While the initial investment in a laser cleaning system may seem high compared to traditional methods, the long-term benefits can outweigh the costs. Laser cleaning does not require any consumables such as abrasive media, chemicals, or brushes, which can add up over time. Laser cleaning is also faster than most other methods, which means less downtime and increased throughput. Moreover, laser cleaning can reduce the need for expensive manual labor, as it can be automated and integrated into production lines.Another advantage of laser cleaning is its reliability. Laser cleaning systems are designed for industrial use and can withstand harsh environments and high volumes of cleaning. They are also easy to maintain and have a long lifespan, which reduces the need for frequent replacements or repairs. Laser cleaning systems can also be customized to meet specific customer needs, such as size, power, wavelength, and automation.In addition to cost-effectiveness and reliability, laser cleaning also offers environmental benefits. Laser cleaning does not generate any hazardous waste, air emissions, or water pollution, making it a sustainable option for companies that value environmental stewardship. Laser cleaning also reduces the use of chemicals and other hazardous materials, which can improve workplace safety and reduce regulatory compliance costs.As laser cleaning technology continues to evolve and improve, its applications are likely to expand as well. Already, laser cleaning is being used in industries such as aerospace, automotive, medical devices, electronics, and cultural heritage preservation. Laser cleaning is also being explored for applications such as graffiti removal, corrosion prevention, and even food processing.Overall, laser cleaning is a cost-effective and reliable solution for industrial cleaning that offers a range of benefits compared to traditional methods. As companies seek to improve their efficiency, quality, and sustainability, laser cleaning is likely to play an increasingly important role in their operations.

Advanced Fiber Laser Head Technology Making Waves in the Industry

Introducing the Latest Innovation in Fiber Laser TechnologyIn recent years, fiber laser technology has revolutionized the industrial sector, offering high precision and efficiency in cutting, welding, and marking applications. One of the key components of a fiber laser system is the laser head, which plays a critical role in delivering the laser beam to the workpiece with utmost accuracy and power. Recently, a leading company has introduced a cutting-edge fiber laser head that promises to take the industry to new heights.The newly developed fiber laser head, known as the [brand name], is a result of years of research and development by a company that has been at the forefront of laser technology for over two decades. This innovative product boasts a number of features that set it apart from other laser heads currently available on the market.One of the key highlights of the [brand name] fiber laser head is its unparalleled precision and reliability. Equipped with state-of-the-art optical components and advanced control systems, this laser head is capable of delivering a stable and uniform laser beam, ensuring consistent cutting and welding quality. The high-speed positioning system further enhances its accuracy, making it ideal for the most demanding industrial applications.Moreover, the [brand name] fiber laser head is designed for maximum versatility and ease of use. Its modular design allows for easy integration with a wide range of fiber laser systems, making it suitable for various manufacturing environments. The user-friendly interface and intuitive controls make it simple for operators to set up and adjust the laser head, minimizing downtime and enhancing productivity.In addition to its technical capabilities, the [brand name] fiber laser head is also geared towards maximizing cost-efficiency for businesses. The advanced energy-saving features help to reduce power consumption without compromising on performance, leading to significant savings in operational costs. Furthermore, its long service life and minimal maintenance requirements contribute to a lower total cost of ownership, making it a highly economical investment for companies of all sizes.The introduction of the [brand name] fiber laser head has generated a great deal of excitement within the industry, with many businesses expressing keen interest in integrating this cutting-edge technology into their operations. The company behind this groundbreaking innovation has a strong track record of delivering reliable and high-quality laser solutions to its customers, and the [brand name] fiber laser head is poised to further solidify its position as a leading provider of laser technology.In light of the growing demand for advanced laser systems, the availability of the [brand name] fiber laser head presents an exciting opportunity for manufacturers looking to enhance their capabilities and stay ahead of the competition. With its unbeatable combination of precision, versatility, and cost-efficiency, this innovative laser head is set to redefine the standards for fiber laser technology and empower businesses to achieve new levels of success in their respective industries.As the industry continues to evolve, it is innovations like the [brand name] fiber laser head that pave the way for progress and drive the advancement of manufacturing technologies. With its cutting-edge features and unmatched performance, this revolutionary product is poised to make a lasting impact on the world of fiber laser technology and empower businesses to achieve new heights of productivity and quality in their operations.

Fiber Laser Engraver for Sale: Unlocking Limitless Engraving Possibilities

Title: Cutting-Edge Used Fiber Laser Engraver Revolutionizes Precision Engraving ProcessesIntroduction:In an era where technological advancements are transforming industries, {Company Name}, a leading provider of cutting-edge machinery solutions, has introduced an exceptional used Fiber Laser Engraver. This revolutionary device aims to redefine the precision engraving landscape, offering unprecedented quality and productivity.The Used Fiber Laser Engraver:The used Fiber Laser Engraver, recently unveiled by {Company Name}, brings forth a myriad of benefits for businesses in various sectors. Capitalizing on the latest advancements in fiber laser technology, this state-of-the-art engraver ensures superior precision, speed, and versatility.This advanced machine utilizes a high-powered fiber laser to etch designs onto a wide range of materials, including metals, plastics, ceramics, and more. With its exceptional accuracy and finer cutting capabilities, it has become an industry favorite, serving the needs of diverse businesses, including manufacturers, jewelry designers, and artists.Precision and Versatility:One of the key advantages of this used Fiber Laser Engraver is its remarkable precision. Equipped with cutting-edge laser technology, the engraver achieves intricate levels of detail, ensuring that even the most complex designs are etched flawlessly. This unparalleled precision allows businesses to showcase their creativity and enhance the aesthetics of their products.Furthermore, the versatility of this engraver makes it an invaluable asset in various industries. Its ability to work on a multitude of materials enables businesses to expand their product offerings. From personalized jewelry and industrial components to intricate artwork and promotional items, this engraver empowers businesses to explore new horizons.Increased Efficiency and Profitability:With its rapid engraving speed, the used Fiber Laser Engraver enables businesses to achieve unmatched levels of efficiency. This enhanced productivity translates into optimized workflow processes, faster turnaround times, and increased profitability. By automating the engraving process, this innovative machine reduces manual labor, streamlines operations, and minimizes the margin for error.Moreover, this engraver boasts excellent reliability and durability, ensuring uninterrupted production for prolonged periods. With reduced downtime and minimal maintenance requirements, businesses can focus on meeting their customers' demands and ultimately bolster their bottom line.Environmentally Friendly and Cost-Effective:In addition to its cutting-edge features, the used Fiber Laser Engraver is also environmentally conscious. Unlike traditional engraving methods that often generate waste or rely on harmful chemicals, this eco-friendly alternative harnesses the power of laser beams. This not only reduces waste but also lowers energy consumption, making it a cost-effective solution for businesses in the long run.Furthermore, the engraver's efficient use of materials contributes to economic savings. By optimizing material usage and minimizing waste, businesses can maximize their resources and minimize production costs.Conclusion:As {Company Name} introduces its remarkable used Fiber Laser Engraver, businesses across various industries can now harness the power of cutting-edge technology to elevate their precision engraving processes. With its unmatched precision, versatility, efficiency, and environmentally friendly characteristics, this state-of-the-art machine is set to revolutionize the way businesses approach engraving.By investing in this advanced engraver, companies can upgrade their capabilities, expand their product offerings, and meet the growing demands of their discerning customers. With {Company Name}'s commitment to delivering innovative solutions, this used Fiber Laser Engraver is poised to dominate the precision engraving landscape and usher in a new era of design and creativity.

High-quality Laser Marking Machine for Gold - Latest Technology

Gold Laser Marking Machine Revolutionizes Product Identification for Manufacturing IndustryIn the fast-paced world of manufacturing, product identification and traceability are crucial for ensuring quality, safety, and regulatory compliance. With the introduction of the Gold Laser Marking Machine by [], manufacturers now have a cutting-edge solution for marking and engraving a wide range of materials with precision and efficiency.The Gold Laser Marking Machine is the latest innovation from [], a leading provider of laser marking and engraving solutions for various industries. Leveraging advanced laser technology, this machine is designed to meet the demanding requirements of modern manufacturing processes, delivering high-quality markings on metals, plastics, ceramics, and more.One of the key features of the Gold Laser Marking Machine is its ability to create permanent, high-contrast markings that are resistant to wear, fading, and corrosion. This is especially important in industries such as aerospace, automotive, and medical device manufacturing, where traceability and part identification are critical for quality control and supply chain management.With its high-speed marking capabilities and precise control, the Gold Laser Marking Machine is suitable for a wide range of applications, including serial numbers, barcodes, logos, and 2D data matrices. This versatility makes it an ideal solution for manufacturers looking to enhance their product identification processes while maintaining efficient production workflows.Furthermore, the Gold Laser Marking Machine is equipped with user-friendly software that allows for easy integration with existing manufacturing systems. This seamless integration enables manufacturers to streamline their marking processes and reduce the risk of errors, ultimately improving productivity and reducing operational costs.In addition to its technical capabilities, the Gold Laser Marking Machine is designed with the needs of the modern manufacturing environment in mind. Its compact and ergonomic design allows for easy installation and integration into production lines, making it a valuable addition to any manufacturing facility.“We are thrilled to introduce the Gold Laser Marking Machine to the market,” said a spokesperson from []. “As a company committed to innovation and continuous improvement, we are confident that this new solution will revolutionize product identification for manufacturers, providing them with the tools they need to meet the evolving demands of their industries.”The introduction of the Gold Laser Marking Machine comes at a time when manufacturers are increasingly seeking advanced marking and identification solutions to keep up with industry trends and regulatory requirements. As global supply chains become more complex, the need for reliable and efficient product traceability has never been greater, and the Gold Laser Marking Machine is poised to address these challenges head-on.Moving forward, [] is dedicated to providing ongoing support and expertise to help manufacturers maximize the potential of the Gold Laser Marking Machine within their production processes. By partnering with their customers, they aim to deliver comprehensive solutions that drive innovation and competitiveness in the manufacturing industry.In conclusion, the Gold Laser Marking Machine represents a significant advancement in product identification technology for the manufacturing industry. With its precision, speed, and versatility, this machine is set to empower manufacturers with the tools they need to succeed in a rapidly changing global marketplace. For companies looking to elevate their product identification and traceability processes, the Gold Laser Marking Machine offers a compelling solution that brings innovation and efficiency to the forefront of manufacturing operations.