New Study Shows Laser Treatment Effectively Reduces Acne Scars

By:Admin

{Company} is a leading provider of laser solutions, offering a wide range of products and services to meet the diverse needs of its clients. With a strong focus on innovation and quality, {Company} has established itself as a trusted partner for businesses across different sectors.

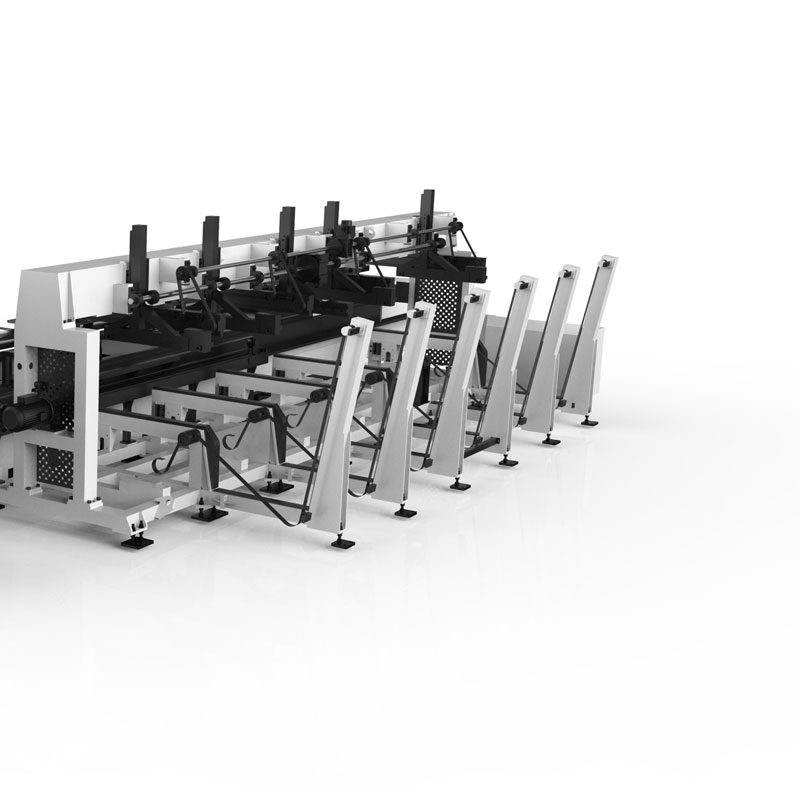

One of the key areas where {Company} has made a significant impact is in the field of manufacturing. By leveraging the power of laser technology, {Company} has helped its clients improve their production processes, achieve higher precision, and enhance their overall efficiency. Whether it's cutting, welding, marking, or engraving, {Company}'s laser solutions have been instrumental in driving productivity and quality for its customers.

In addition to manufacturing, {Company} has also been actively involved in the development of laser technology for medical and scientific applications. The company's cutting-edge laser systems have been used in research laboratories and medical facilities, contributing to advancements in various fields such as dermatology, ophthalmology, and more.

Recently, {Company} introduced a new line of laser products that have garnered significant attention in the industry. The {Product Name} series, powered by the latest laser technology, offers enhanced performance and versatility for a wide range of applications. Whether it's high-precision cutting for industrial materials or delicate surgical procedures in medical settings, the {Product Name} series is designed to deliver exceptional results.

One of the key features of the {Product Name} series is its advanced laser control technology, which allows for precise and consistent operation. This level of control is crucial for industries where accuracy is paramount, and {Company}'s new line of products has set a new standard in this regard.

Furthermore, the {Product Name} series is also designed with user convenience in mind. From intuitive interfaces to easy maintenance, {Company} has prioritized user-friendly design in the development of these new laser systems. This focus on usability has been well-received by clients who have embraced the {Product Name} series for their respective needs.

"We are thrilled to introduce the {Product Name} series to the market," said {Company} CEO. "This new line of products represents our commitment to pushing the boundaries of laser technology and providing our clients with the best-in-class solutions. We believe that the {Product Name} series will make a significant impact across various industries and continue to uphold our reputation for excellence."

In addition to the launch of the {Product Name} series, {Company} has also announced plans to further expand its research and development efforts in laser technology. The company is investing in cutting-edge equipment and talent to ensure that it stays at the forefront of innovation in this rapidly evolving field.

As the demand for laser technology continues to grow, {Company} is well-positioned to meet the needs of its clients with its comprehensive range of products and services. With a strong track record of success and a clear vision for the future, {Company} is poised to maintain its leadership in the laser technology industry.

Company News & Blog

Top Fiber Optic Lasers You Need to Know About

Fiber Optic Lasers: The Future of High-Speed, Precision TechnologyThe world of technology is constantly evolving, and one of the most exciting advancements in recent years has been the development of fiber optic lasers. These cutting-edge devices are poised to revolutionize a wide range of industries, from telecommunications and manufacturing to medical imaging and defense. With their ability to transmit data at lightning-fast speeds and with incredible precision, fiber optic lasers are on track to become an essential tool for the 21st century.Leading the charge in this revolutionary technology is [Company], a global leader in the development of advanced laser systems. Founded in [year], [Company] has been at the forefront of laser innovation for over [number] years, continually pushing the boundaries of what is possible with light-based technologies. From their state-of-the-art research and development facilities to their global network of manufacturing and distribution centers, [Company] is dedicated to bringing the power of fiber optic lasers to businesses and organizations around the world.So, what exactly sets fiber optic lasers apart from other types of lasers? The key lies in their use of optical fibers to deliver the laser light. Unlike traditional lasers, which rely on bulk optics to transmit and focus the light, fiber optic lasers use thin, flexible optical fibers to carry the laser beam to its target. This allows for much greater precision and control, as well as the ability to transmit the laser light over much longer distances without losing intensity or focus.The benefits of fiber optic lasers are clear. With their ability to transmit data at speeds exceeding [number] gigabits per second, fiber optic lasers are ideal for high-speed communications and data transfer. This makes them invaluable for telecommunications companies, data centers, and internet service providers, where the need for reliable, high-speed connections is paramount. Additionally, their precision and focus make fiber optic lasers perfect for a wide range of manufacturing and machining applications, from cutting and welding to engraving and 3D printing.In the world of medicine, fiber optic lasers are enabling a new generation of advanced imaging and surgical techniques. Their ability to deliver highly focused beams of light makes them perfect for delicate surgical procedures, such as eye surgery or tumor removal. They are also being used to develop new diagnostic tools, such as high-resolution endoscopes and imaging systems, which are revolutionizing the way doctors diagnose and treat a wide range of medical conditions.But perhaps the most exciting potential for fiber optic lasers lies in the field of defense and security. With their ability to transmit data over long distances with incredible precision, fiber optic lasers are being used to develop advanced weapons systems, surveillance technologies, and communication networks for military and law enforcement organizations. Their ability to transmit data securely and at high speeds makes them ideal for a wide range of applications, from long-range communications to precision targeting.With all of these incredible potential applications, it's no wonder that fiber optic lasers are being hailed as the technology of the future. And at the forefront of this revolution is [Company], whose extensive experience and expertise in laser technology make them the ideal partner for businesses and organizations looking to harness the power of fiber optic lasers. Whether it's developing custom laser systems for a specific application or providing ongoing support and maintenance for existing laser systems, [Company] is committed to providing their customers with the highest level of service and expertise.As we look to the future, it's clear that fiber optic lasers will play a pivotal role in shaping the world of technology and innovation. With their unmatched speed, precision, and versatility, fiber optic lasers are poised to revolutionize a wide range of industries, from telecommunications and manufacturing to medicine and defense. And with [Company] leading the way, businesses and organizations around the world can rest assured that they are in good hands as they embark on this exciting new chapter in laser technology.

State-of-the-Art Laser Co2 Engraver: Revolutionizing Engraving Techniques

Title: Laser CO2 Engraver Revolutionizing the Manufacturing IndustryIntroduction:In recent years, the manufacturing industry has witnessed significant advancements in technology, one of which is the Laser CO2 Engraver. Developed by a pioneering company, this cutting-edge engraving machine has revolutionized the manufacturing process, providing exceptional precision, efficiency, and versatility to businesses across various sectors.Company Introduction:{Company Name} is a leading innovator in laser technology, specializing in the development of state-of-the-art engraving machines. With a strong commitment to improving manufacturing processes, the company has a proven track record of introducing groundbreaking solutions that enhance productivity and quality. Through continuous research and development, {Company Name} has become a trusted name in the industry, catering to a wide range of customers globally.News Content:The Laser CO2 Engraver, developed by {Company Name}, is quickly gaining recognition for its ability to transform the manufacturing industry. This revolutionary machine harnesses the power of lasers to engrave designs and markings with unmatched precision on various materials like wood, glass, leather, and plastics.With advancements in technology, laser engraving has become an indispensable tool for businesses wanting to add intricate designs and logos to their products. The Laser CO2 Engraver surpasses expectations by providing even the most complex designs accurately and efficiently, eliminating human error and allowing for high-quality results. This has made it the preferred choice for manufacturers across industries such as electronics, jewelry, packaging, and promotional products.One of the standout features of the Laser CO2 Engraver is its ability to handle a wide range of materials. Whether it's delicate jewelry pieces or sturdy industrial parts, this engraver ensures precise markings that remain permanent and aesthetically pleasing. Moreover, the laser-based technology eliminates the need for traditional engraving tools, minimizing maintenance costs and allowing for faster turnaround times.In addition to its versatility, the Laser CO2 Engraver boasts exceptional speed. It can complete intricate engravings in a fraction of the time compared to conventional methods. This not only enhances productivity within manufacturing processes but also allows businesses to meet tight deadlines, resulting in improved customer satisfaction.Furthermore, the Laser CO2 Engraver offers environmental advantages. Unlike traditional engraving methods that emit harmful chemicals into the atmosphere, this machine operates on a clean and eco-friendly laser system. It minimizes waste and enables manufacturers to adhere to stringent environmental regulations, making it an ideal choice for eco-conscious businesses.{Company Name} has not only developed a cutting-edge engraving machine but also provides comprehensive support and training to its customers. With a team of highly skilled technicians and engineers, the company ensures that clients can maximize the efficiency and potential of the Laser CO2 Engraver. This commitment to customer satisfaction has garnered {Company Name} a loyal and expanding client base.Looking ahead, {Company Name} aims to continually refine the Laser CO2 Engraver and introduce further innovations to meet the evolving needs of the manufacturing industry. By staying at the forefront of laser technology, the company strives to empower businesses and enable them to reach new heights of success in their respective fields.Conclusion:The Laser CO2 Engraver, developed by {Company Name}, has emerged as a game-changer in the manufacturing industry. Its precision, versatility, speed, and eco-friendly operation have positioned it as a preferred choice for businesses across various sectors. With continued advancements and a commitment to customer satisfaction, {Company Name} is ensuring that manufacturing processes become more efficient, reliable, and sustainable.

Top Laser Cutting Techniques for Precision and Efficiency

The Laser Cut, a cutting-edge technology solution developed by a leading laser technology company, is revolutionizing the manufacturing industry. This innovative technology is allowing manufacturers to streamline production processes, improve precision and efficiency, and ultimately reduce costs. With its advanced features and capabilities, The Laser Cut is quickly becoming the go-to solution for businesses looking to stay competitive in today's fast-paced market.The Laser Cut utilizes state-of-the-art laser technology to cut through various materials with unparalleled accuracy. Its high-powered laser beam can cut through metal, plastic, wood, and other materials with ease, allowing for complex and intricate designs to be produced with precision. This level of accuracy and detail is essential for industries such as aerospace, automotive, and electronics, where even the smallest error can have significant consequences.In addition to its cutting capabilities, The Laser Cut also offers a range of other features that make it an indispensable tool for manufacturers. Its user-friendly interface and intuitive controls make it easy for operators to program and operate, while its automated functions allow for continuous and uninterrupted production. This not only reduces the need for manual labor but also minimizes the risk of human error, resulting in consistently high-quality output.Furthermore, The Laser Cut is equipped with a range of safety features to ensure the protection of both operators and the equipment itself. These include safety sensors, protective barriers, and emergency stop functions, all of which contribute to a safe and secure working environment. This has made The Laser Cut a preferred choice for manufacturers who prioritize workplace safety and regulatory compliance.In terms of efficiency, The Laser Cut offers significant advantages over traditional cutting methods. Its high-speed cutting capabilities and low maintenance requirements make it a cost-effective solution for companies looking to improve productivity and reduce operational expenses. By optimizing manufacturing processes and minimizing waste, The Laser Cut is helping businesses across various industries to achieve higher levels of efficiency and profitability.One of the key benefits of The Laser Cut is its versatility. Its ability to cut through a wide range of materials and its compatibility with various design software make it suitable for a diverse range of applications. From producing intricate components for the medical industry to creating custom parts for the automotive sector, The Laser Cut is proving to be an invaluable asset for manufacturers looking to diversify their product offerings and expand their capabilities.In addition to its cutting-edge technology, the company behind The Laser Cut is committed to providing exceptional customer support and service. With a team of experienced engineers and technicians, they offer comprehensive training, technical assistance, and maintenance services to ensure that customers get the most out of their investment. This dedication to customer satisfaction has helped to establish the company as a trusted and reliable partner for businesses looking to adopt advanced laser technology.As the manufacturing industry continues to evolve, The Laser Cut is poised to play a critical role in shaping its future. Its unparalleled precision, efficiency, and versatility make it a game-changing solution for businesses looking to stay ahead of the curve. With its advanced features and commitment to customer satisfaction, The Laser Cut is set to become the industry standard for laser cutting technology.

Cost-Effective and Reliable Laser Cleaning Solution with In-Line Process Control for Industrial Use

Laser cleaning is cost-effective and reliable, making it an attractive solution for a range of industries and applications. From aerospace and automotive to medical device manufacturing and electronics, laser cleaning offers a non-destructive, precise, and eco-friendly way to remove contaminants, coatings, oxides, and other unwanted substances from surfaces.One of the latest developments in laser cleaning technology is the integration of process monitoring and in-line process control. This allows for real-time feedback and adjustment of laser parameters, ensuring consistent and optimal cleaning results. One company that has pioneered this approach is (brand name), a leading provider of laser cleaning systems."We believe that laser cleaning is the future of industrial cleaning," says (spokesperson). "Our systems offer a level of precision, efficiency, and safety that traditional methods simply can't match. With the addition of process monitoring and control, our customers can further improve their productivity, quality, and cost-effectiveness."So, how does laser cleaning work? Essentially, a high-intensity laser beam is focused on the surface to be cleaned, causing the contaminants to evaporate or ablate. The laser light is directed with precision using mirrors, lenses, and scanners, allowing for selective cleaning of specific areas or shapes. Unlike mechanical or chemical treatments, laser cleaning does not cause any physical or chemical damage to the substrate, and does not generate any waste or residue to dispose of.Laser cleaning can be used on a wide range of materials, including metals, ceramics, plastics, glass, and composites. It can remove rust, paint, grease, adhesives, carbon, oxides, mold release agents, and other contaminants. Laser cleaning can also be used to prepare surfaces for subsequent treatments such as bonding, welding, painting, or coating.One of the key advantages of laser cleaning is its cost-effectiveness. While the initial investment in a laser cleaning system may seem high compared to traditional methods, the long-term benefits can outweigh the costs. Laser cleaning does not require any consumables such as abrasive media, chemicals, or brushes, which can add up over time. Laser cleaning is also faster than most other methods, which means less downtime and increased throughput. Moreover, laser cleaning can reduce the need for expensive manual labor, as it can be automated and integrated into production lines.Another advantage of laser cleaning is its reliability. Laser cleaning systems are designed for industrial use and can withstand harsh environments and high volumes of cleaning. They are also easy to maintain and have a long lifespan, which reduces the need for frequent replacements or repairs. Laser cleaning systems can also be customized to meet specific customer needs, such as size, power, wavelength, and automation.In addition to cost-effectiveness and reliability, laser cleaning also offers environmental benefits. Laser cleaning does not generate any hazardous waste, air emissions, or water pollution, making it a sustainable option for companies that value environmental stewardship. Laser cleaning also reduces the use of chemicals and other hazardous materials, which can improve workplace safety and reduce regulatory compliance costs.As laser cleaning technology continues to evolve and improve, its applications are likely to expand as well. Already, laser cleaning is being used in industries such as aerospace, automotive, medical devices, electronics, and cultural heritage preservation. Laser cleaning is also being explored for applications such as graffiti removal, corrosion prevention, and even food processing.Overall, laser cleaning is a cost-effective and reliable solution for industrial cleaning that offers a range of benefits compared to traditional methods. As companies seek to improve their efficiency, quality, and sustainability, laser cleaning is likely to play an increasingly important role in their operations.

New fiber laser cutting machines offer unparalleled precision and efficiency, with all-in-one cells to maximize savings.

Fiber Laser Cutting: The Future of Precision ManufacturingIn today's fast-paced manufacturing world, precision and speed are critical factors that determine the success of a business. To stay ahead of the competition, manufacturers are always looking for new and innovative technology to help them improve their efficiency and productivity.One such technology that is rapidly gaining popularity is fiber laser cutting. Unlike traditional cutting methods, fiber laser cutting uses a high-powered laser beam to cut through a wide range of materials with unmatched precision, speed, and efficiency.Here are some of the key benefits of fiber laser cutting:Unmatched Accuracy: One of the most significant advantages of fiber laser cutting is its unmatched accuracy. The laser beam is incredibly precise and can cut through materials with a precision of up to 0.001mm. This level of accuracy is impossible to achieve with traditional cutting methods.High Speed: In addition to accuracy, fiber laser cutting is also incredibly fast. The laser beam can cut through materials at a rate of up to 40 meters per minute, which is much faster than traditional cutting methods like sawing or milling.Versatile: Fiber laser cutting can cut through a wide range of materials, including metal sheets, tubes, pipes, and profiles. This versatility makes it an ideal solution for a wide range of industries, including automotive, aerospace, and construction.Minimal Waste: Traditional cutting methods like sawing or milling produce a significant amount of waste material. In contrast, fiber laser cutting produces minimal waste, making it a more environmentally friendly option.Cost-Effective: While fiber laser cutting machines are typically more expensive to purchase than traditional cutting machines, they offer significant cost savings over the long term. The high precision and speed of fiber laser cutting mean that less waste is produced, resulting in lower material costs.If you are interested in investing in a fiber laser cutting machine, you may be wondering about the cost of the cutting head.The cost of a fiber laser cutting head can vary depending on several factors, including the power of the laser, the size of the cutting head, and the specific features of the head.On average, a fiber laser cutting head can range in price from a few thousand dollars to tens of thousands of dollars. However, it's important to note that the cost of the cutting head is just one factor to consider when purchasing a fiber laser cutting machine.Ultimately, the cost-effectiveness of a fiber laser cutting machine will depend on several factors, including your specific business needs, the materials you plan to cut, and the volume of production required.In conclusion, fiber laser cutting is an innovative technology that offers unmatched precision, speed, and efficiency. If you're looking to improve your manufacturing processes, investing in a fiber laser cutting machine could be the solution you need. While the cost of the cutting head is an important consideration, it's just one factor to consider when evaluating the overall cost-effectiveness of the technology.

How Fiber Laser Cutting Systems Are Improving Manufacturing Processes

Fiber Laser Cutting Systems are revolutionizing the metal cutting industry with their precision, speed, and efficiency. One of the leading manufacturers of these cutting-edge machines is {Company X}, a global leader in advanced manufacturing technology. With a strong focus on innovation and customer satisfaction, {Company X} has been at the forefront of the industry for over two decades.The {Company X} Fiber Laser Cutting Systems are equipped with state-of-the-art technology that allows for fast and accurate cutting of a wide range of materials, including stainless steel, aluminum, copper, and titanium. These cutting systems are designed to meet the needs of various industries, from automotive and aerospace to medical and consumer electronics.One of the key features of {Company X} Fiber Laser Cutting Systems is their high precision, which is made possible by advanced motion control systems and intelligent software. This level of precision ensures that the finished parts meet the strictest quality standards, making them ideal for use in the most demanding applications.In addition to precision, {Company X} Fiber Laser Cutting Systems are known for their speed and efficiency. With high-powered laser sources and high-speed cutting heads, these machines can quickly and accurately cut complex shapes and intricate patterns, reducing production time and increasing overall productivity.Furthermore, {Company X} offers a range of Fiber Laser Cutting Systems to suit different production needs, from small, compact machines for smaller workshops to large, automated systems for high-volume production facilities. This flexibility makes {Company X} a preferred choice for businesses of all sizes, seeking to enhance their metal cutting capabilities.{Company X} not only provides cutting-edge machines but also offers comprehensive support and services to ensure that their customers get the most out of their investment. This includes training programs, maintenance services, and technical support, all aimed at keeping the Fiber Laser Cutting Systems running at peak performance.With a strong commitment to research and development, {Company X} is constantly pushing the boundaries of what is possible with Fiber Laser Cutting technology. Their team of engineers and technicians are always working on new innovations and improvements to further enhance the capabilities of their cutting systems, staying ahead of the curve and setting new industry standards.Through strategic partnerships and collaborations with other industry leaders, {Company X} continues to drive the advancement of Fiber Laser Cutting technology, ensuring that their customers have access to the latest and most advanced solutions for their metal cutting needs.In conclusion, {Company X} Fiber Laser Cutting Systems are setting new benchmarks in the metal cutting industry, providing unmatched precision, speed, and efficiency to a wide range of businesses. With a strong focus on innovation, customer satisfaction, and comprehensive support, {Company X} remains a trusted partner for those seeking to elevate their metal cutting capabilities. As the demand for high-quality, precision-cut parts continues to grow across various industries, {Company X} is well-positioned to meet and exceed these demands with their cutting-edge technology and unwavering commitment to excellence.

CO2 Laser Cutting Services: Precision Cutting for Your Needs

article about the advantages of CO2 laser cutting in industrial applications.CO2 Laser Cutting Technology for Industrial ApplicationsLaser cutting is a critical process that is used in industrial applications, such as fabrication, manufacturing, and construction. The technological advancements in CO2 laser cutting have made it a preferred choice in many industries due to its precision, accuracy, and cost-effectiveness. As a result, many businesses are turning to CO2 laser cutting as an innovative way to improve their manufacturing and production capabilities.CO2 laser cutting is a highly efficient technology that uses a highly focused laser beam to cut through various materials, such as metal, plastic, wood, and glass. The laser beam forms an intense and coalesced stream of light that is capable of creating precise cuts and shapes in the material. The benefits of CO2 laser cutting are numerous, including faster processing speeds, better accuracy, and cleaner cuts.Faster Processing Speeds – The CO2 laser cutting technology is capable of operating at high speeds, which is ideal for mass production. This ensures that businesses can produce large quantities of products in a relatively short period. The speed of the laser cutting machine can be adjusted to match the specific needs of the project, allowing for flexibility in production.Better Accuracy – CO2 laser cutting technology is highly accurate, and it can cut materials with great precision. The technology uses a computer-controlled system, which ensures that the machine makes accurate cuts according to the specifications of the project. The cuts are consistent, and there is minimal deviation from the desired dimensions. This level of accuracy is critical in industrial applications because it ensures that the products being produced are of a high-quality and meet the required standards.Cleaner Cuts – CO2 laser cutting technology is renowned for creating smooth, clean cuts. The laser beam is incredibly precise, and it vaporizes the material being cut, leaving no residue or debris. This results in a cleaner cut, which is especially important in industries that require high-quality finishes. For example, in the automotive industry, CO2 laser cutting technology is used to cut metal components that require a precise finish.Cost-Effective – CO2 laser cutting technology is a cost-effective method of cutting, especially when compared to traditional cutting methods. The technology is efficient, and it does not require much maintenance. Additionally, CO2 laser cutting produces minimal waste, which means that businesses can save money on material costs. This is because the machine is designed to use materials efficiently, resulting in higher material utilization rates.Versatility – CO2 laser cutting technology is versatile and can be used to cut a wide range of materials, such as metal, plastic, wood, and glass. This flexibility makes it an ideal option for businesses that deal with multiple materials because they can use the same machine to cut different materials, which saves time and money.The rise of CO2 laser cutting technology has revolutionized the manufacturing and fabrication industry. Businesses that have adopted this technology have reported significant improvements in their production capabilities, such as better accuracy, faster processing speeds, and cleaner cuts. The technology has also enabled businesses to save money on material costs and increase their material utilization rates.In conclusion, the CO2 laser cutting technology is a game-changer in the industrial sector due to its efficiency, versatility, and precision. Its vast benefits surpass its traditional counterparts, making it the most preferred cutting technology in modern industry. The technology has revolutionized how businesses approach manufacturing and fabrications, and those that have adopted it can attest to its transformative capabilities.

Top Laser CNC Machines for Precision Cutting and Engraving

The manufacturing industry has seen significant advancements in technology in recent years, especially in the field of laser CNC machines. These cutting-edge machines have revolutionized the way companies approach manufacturing, with their precision, speed, and versatility.One company that has been at the forefront of this technological revolution is {}. Established in 1995, they have been providing innovative and reliable laser CNC machines to a wide range of industries, including automotive, aerospace, medical, and electronics.Their commitment to research and development has led to the creation of the best laser CNC machine in the market, which has set a new standard for efficiency and performance. These machines are capable of cutting a variety of materials with unmatched precision, whether it's metal, plastic, wood, or even delicate materials like ceramics and glass.One of the key features that sets their laser CNC machines apart is their advanced laser technology, which ensures clean and precise cuts, resulting in high-quality finished products. Their machines also offer a high level of customization, allowing customers to tailor the machine to their specific needs and requirements.In addition to their cutting-edge technology, the company also prides itself on providing excellent customer service and support. Their team of experts is dedicated to helping customers find the best solution for their manufacturing needs, offering guidance and advice every step of the way.Furthermore, their commitment to sustainability sets them apart from the competition. Their laser CNC machines are designed to minimize waste and energy consumption, making them an environmentally friendly choice for manufacturers looking to reduce their carbon footprint.With a global presence, the company has established a strong reputation for delivering reliable and high-performing laser CNC machines to customers around the world. Their machines have been used in a wide range of applications, from small-scale businesses to large-scale industrial operations, proving their versatility and reliability.The company's dedication to innovation and quality has earned them numerous accolades and certifications, solidifying their position as a leader in the laser CNC machine industry. They continue to invest in research and development, ensuring that their machines remain at the cutting edge of technology.In conclusion, the best laser CNC machine offered by {} represents the pinnacle of technological innovation and quality in the manufacturing industry. With their advanced features, customization options, and commitment to sustainability, it's no wonder they are the go-to choice for businesses looking to elevate their manufacturing processes.Whether it's precision cutting, intricate designs, or high-volume production, their laser CNC machines deliver unmatched performance and reliability. With their dedication to customer satisfaction and continuous improvement, {} is poised to remain a dominant force in the laser CNC machine industry for years to come.

Top Cutting and Bending Machine: A Complete Guide

Cutting and Bending Machine revolutionizes metalworking industryThe metalworking industry has taken a significant leap forward with the introduction of the cutting and bending machine by a leading manufacturing company. This innovative machine is designed to streamline the metal fabrication process and improve efficiency in a wide range of applications.The cutting and bending machine is capable of precisely cutting and shaping various types of metal, including steel, aluminum, and copper. Its advanced technology and precision-engineered components enable it to deliver accurate and consistent results, making it a valuable asset for manufacturers and fabricators.The machine's cutting capabilities are especially impressive, as it is able to cut through thick metal sheets with ease and precision. This is particularly beneficial for industries that require intricate and complex metal components, such as the aerospace and automotive sectors. In addition, the machine's bending capabilities allow for the creation of custom metal shapes and structures, offering endless possibilities for creative and innovative designs.One of the key features of this cutting and bending machine is its user-friendly interface, which makes it easy to operate and adjust for different applications. This intuitive interface, combined with the machine's high-speed performance, allows for increased productivity and reduced downtime, leading to cost savings for manufacturers.Furthermore, the cutting and bending machine is equipped with advanced safety features to ensure the well-being of operators and prevent accidents in the workplace. This includes protective barriers and emergency stop buttons, as well as automatic shut-off mechanisms in case of a malfunction.The company behind this cutting and bending machine is a renowned leader in the manufacturing industry, with a long-standing reputation for delivering high-quality and reliable machinery. With a commitment to innovation and customer satisfaction, the company has continuously invested in research and development to create cutting-edge solutions for the metalworking industry.In addition to the cutting and bending machine, the company offers a comprehensive range of metal fabrication equipment and services, including laser cutting machines, press brakes, and welding systems. This full suite of products and expertise enables the company to provide end-to-end solutions for its clients, from design and prototyping to production and assembly.The company's dedication to excellence is further demonstrated through its emphasis on customer support and after-sales service. With a team of experienced technicians and engineers, the company offers training, maintenance, and technical assistance to ensure that its clients maximize the potential of their equipment and achieve optimal results.As a testament to its commitment to quality and innovation, the company has received numerous accolades and certifications for its products and services. This includes ISO 9001 certification for its quality management system, as well as industry awards for its cutting-edge machinery and technological advancements.In light of the growing demand for efficient and reliable metal fabrication solutions, the cutting and bending machine is set to make a significant impact on the industry. Its ability to deliver precise and high-quality results, combined with the expertise and support provided by the manufacturing company, positions it as a game-changer for manufacturers and fabricators seeking to stay ahead in a competitive market.Overall, the cutting and bending machine represents a new era in metalworking, offering unprecedented capabilities and efficiency for a wide range of applications. With its innovative technology, user-friendly interface, and comprehensive support, it is poised to redefine the standards of metal fabrication and set new benchmarks for the industry as a whole.

Benefits of Laser Welding Machine in Industrial Welding Processes

Laser Welding Machine Manufactured by Chinese Company Boasts High QualityA Chinese company has recently developed a state-of-the-art laser welding machine that promises to revolutionize the welding industry. The machine has been designed to offer high quality welding services with minimal effort, and has already become a popular choice among manufacturing companies across the globe.The Fiber Welding Machine, as it's called, uses laser technology to weld metal and other materials together. It's a non-contact process, which means that there's no need to physically touch the materials being welded, resulting in a clean and precise finish.One of the main advantages of this machine is that it produces a smooth and uniform welding surface, with no protruding welding spots. This eliminates the need for post-weld grinding and polishing, which makes the entire welding process more efficient and cost-effective.According to the company spokesperson, "Our Fiber Welding Machine is incredibly accurate and reliable. It's designed to handle a wide range of materials, from thin sheet metals to thick blocks of steel. And because it's a non-contact process, it minimizes the risk of distortion or damage to the materials being welded."The laser technology used in this machine is known for its precision and speed. The laser beam is controlled by a computer program, which ensures that the welding process follows a specific pattern and shape. This makes it ideal for mass production processes, where speed and efficiency are key factors.Furthermore, the Fiber Welding Machine takes up very little space in the manufacturing facility. It's compact and easy to move around, making it perfect for small workshops or factories with limited space. It's also relatively low maintenance, which means it doesn't require a lot of upkeep or repair work.The Chinese company behind this innovation has been in the welding business for many years. They've worked with some of the biggest names in the industry, providing quality welding services for a wide range of applications. Their experience and expertise have helped them develop this cutting-edge technology, which is now being used by companies all over the world.The Fiber Welding Machine has received glowing reviews from its users. "This machine has transformed the way we do welding," says one satisfied customer. "It's so easy to use and produces excellent results every time."Another customer adds, "We were struggling with post-weld polishing and grinding, which was taking up a lot of time and resources. But with this machine, we don't have to worry about that anymore. It saves us a lot of time and money."The Chinese company is now working to improve the machine even further, by adding more features and capabilities. They're also investing in research and development, with the goal of bringing even more advanced welding machines to the market.In conclusion, the Fiber Welding Machine is a game-changer for the welding industry. Its precision, speed, and efficiency make it an ideal choice for manufacturing companies looking to increase their productivity and reduce their costs. As this technology continues to evolve, we can expect even more exciting innovations from this Chinese company.